The Advantages of Steel Cable Tray Making Roll Forming Machines

In today’s fast-paced industrial landscape, efficient production methods are crucial for meeting the growing demand for high-quality products. Steel cable trays are vital components in various sectors, including construction, telecommunications, and electrical systems. To cater to this demand, the steel cable tray making roll forming machine has emerged as an invaluable asset for manufacturers.

What is a Roll Forming Machine?

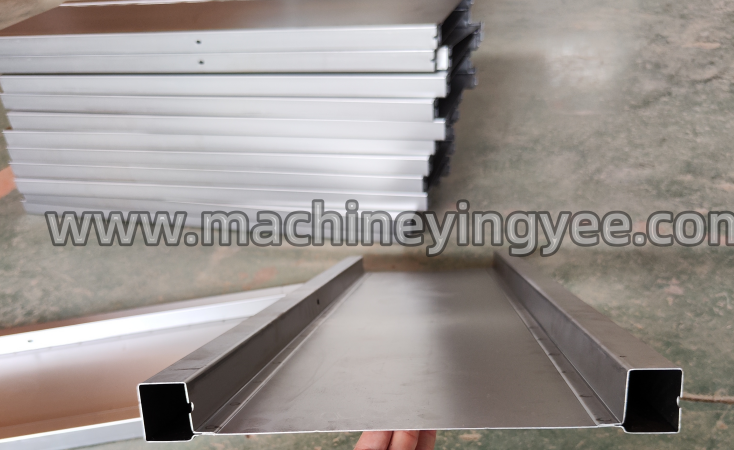

A roll forming machine is a versatile piece of equipment used for fabricating metal profiles. The process involves feeding a flat metal sheet, typically made of steel, through a series of rollers that gradually shape it into the desired profile. This method is particularly effective for producing high-volume, uniform products like cable trays. The roll forming process ensures consistency, precision, and efficiency, making it ideal for manufacturers looking to optimize production lines.

Benefits of Steel Cable Tray Making Machines

1. High Efficiency and Speed The roll forming process is known for its ability to produce large quantities of metal profiles quickly. Once set up, the machine can continuously feed and shape steel into cable trays with minimal downtime. This efficiency is crucial for manufacturers who need to meet tight deadlines and fulfill large orders.

2. Cost-Effectiveness While the initial investment in a roll forming machine may be significant, the long-term savings can be substantial. These machines reduce labor costs because they require fewer operators and minimize material waste due to precise shaping. Over time, the operational savings can outweigh the upfront costs, making it a wise investment for businesses.

3. Customization One of the standout features of steel cable tray making machines is the ability to produce a variety of tray sizes and designs. Manufacturers can easily adjust the rollers to create different profiles, accommodating various project requirements. This flexibility allows for customized solutions that can meet specific client needs without the need for additional tooling or extensive modification.

4. Durability and Quality Steel cable trays require high strength and durability, especially in demanding environments. Roll forming machines are capable of producing robust trays that can withstand heavy loads and harsh conditions. The continuous manufacturing process also ensures that the product maintains high quality and uniformity, crucial for safety and reliability in electrical systems.

5. Eco-Friendly Steel is a recyclable material, and using a roll forming process minimizes waste. The efficiency of the method means that there is less scrap material generated compared to other manufacturing processes, making it an environmentally friendly option for producing cable trays.

Conclusion

In conclusion, the steel cable tray making roll forming machine represents a significant advancement in manufacturing technology. Its combination of efficiency, cost-effectiveness, customization capabilities, durability, and environmental benefits makes it an essential tool for any manufacturer in the electrical and construction industries. As demand for high-quality cable management solutions continues to grow, investing in a steel cable tray making machine could prove to be a strategic move for businesses looking to enhance production and remain competitive in the market.