Steel Curving Unistrut Roll Forming Machine An Essential Tool for Modern Construction

In the evolving landscape of construction and manufacturing, efficiency and versatility are paramount. Among the essential tools that have emerged to meet these demands is the steel curving unistrut roll forming machine. This innovative piece of equipment plays a critical role in the production of steel channels used in a variety of applications, from electrical applications to structural supports, making it a cornerstone in modern construction projects.

The main function of the steel curving unistrut roll forming machine is to shape steel into the desired profiles and curves. Unistrut, known for its channel framing systems, provides a robust solution for mounting lighting, HVAC systems, and other mechanical components within buildings. With the roll forming machine, manufacturers can create high-quality, precision-formed steel components efficiently and cost-effectively.

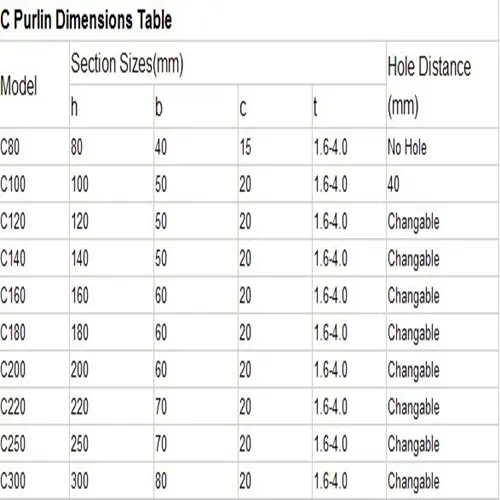

One of the most significant advantages of using a roll forming machine is its ability to produce consistent and uniform profiles. The machine operates by feeding a flat metal strip through a series of rollers, which gradually shape the steel until it reaches its final form. This process allows for minimal material wastage and higher accuracy compared to traditional methods. Additionally, the machine is capable of accommodating various thicknesses and widths of metal, enabling manufacturers to tailor their products to specific project requirements.

Curving capabilities bring another level of versatility to the table. The ability to curve unistrut channels allows for innovative designs in architectural and engineering applications. Whether it's constructing arches or creating complex frameworks, the steel curving unistrut roll forming machine enables designers to push the boundaries of what's possible in construction. The consistent quality of curves produced also ensures structural integrity, making it a preferred choice for many contractors.

Moreover, modern roll forming machines are often equipped with advanced technology, such as PLC (Programmable Logic Controller) systems, which facilitate user-friendly operation and precise control over the manufacturing process. Operators can easily adjust settings to accommodate different specifications, ensuring that production runs are optimized without compromising quality.

The demand for steel curving unistrut roll forming machines has steadily increased as construction projects become more sophisticated and customized. Industries are increasingly seeking out this technology to gain a competitive edge, improve production capabilities, and reduce lead times. With an ever-growing emphasis on sustainable practices, the efficiency that these machines provide supports reduced waste and lower energy consumption, aligning with global sustainability goals.

In conclusion, the steel curving unistrut roll forming machine is a vital asset in today’s construction industry. Its ability to produce precise, high-quality steel profiles and curves not only enhances design possibilities but also boosts efficiency and sustainability. As the industry continues to innovate, these machines will play an even more prominent role in shaping the future of construction, meeting the demands of an increasingly complex market. Whether for large-scale commercial projects or bespoke design works, the steel curving unistrut roll forming machine stands out as an indispensable tool in modern manufacturing.