Steel Cable Tray Making Roll Forming Machine

In today's rapidly evolving industrial landscape, the demand for efficient and effective production processes is paramount. One of the key components facilitating this efficiency is the steel cable tray making roll forming machine. This innovative machinery plays a crucial role in the manufacturing of cable trays, which are essential for supporting and securing electrical cables in various settings, including commercial buildings, industrial facilities, and data centers.

The Importance of Cable Trays

Cable trays serve a critical function in electrical and data network setups. They help organize and protect cables, ensuring safety and preventing damage. By providing a structured environment for cable routing, these trays facilitate easier maintenance and upgrades. As construction and technology industries grow, the need for high-quality, durable cable trays has surged, driving demand for efficient manufacturing solutions.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, typically steel, is passed through sets of rollers to achieve the desired cross-sectional profile. The process is highly efficient, producing consistent, precise shapes with minimal waste. The use of a roll forming machine for cable tray production streamlines the manufacturing process, allowing for large volumes of product to be created with high repeatability.

Features of Steel Cable Tray Making Roll Forming Machines

Modern steel cable tray making roll forming machines are equipped with advanced features that enhance production capabilities

. These features commonly include1. High-Speed Operation Advanced roll forming machines can operate at high speeds, significantly increasing output while maintaining product quality.

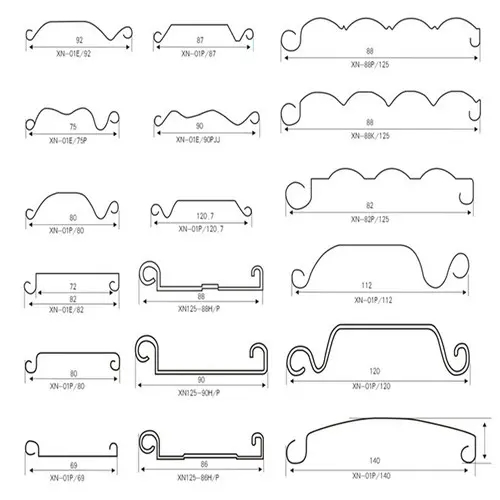

2. Adjustable Roll Sets Many machines offer adjustable roll sets, allowing manufacturers to easily change designs and accommodate various tray widths and heights.

3. Material Versatility While steel is the primary material used, many machines can also process aluminums, creating opportunities for businesses to diversify their product offerings.

4. Integrated Cutting and Punching Most modern machines come with integrated cutting and punching functionalities, allowing for real-time adjustments during the forming process. This integration reduces production time and enhances efficiency.

5. Computer Numerical Control (CNC) The inclusion of CNC technology in roll forming machines enables precise control over the forming process, resulting in minimal tolerance errors and consistent quality.

Applications in Industry

The applications of steel cable tray making roll forming machines are vast. Industries ranging from telecommunications to power distribution benefit from the high-quality cable trays produced using this technology. Utilities often require extensive cable management systems that can protect and support high-voltage lines. Similarly, data centers need efficient cable management solutions to handle the numerous cables necessary for operations, making these machines invaluable.

Conclusion

The steel cable tray making roll forming machine represents a significant advancement in manufacturing technology. It not only boosts production efficiency but also ensures the high-quality output needed in modern industries. As the demand for organized and safe cable management systems continues to grow, investing in such machines is becoming increasingly vital for manufacturers seeking to stay competitive in the market. By following the trends and adopting state-of-the-art technology, companies can meet the evolving needs of their customers while optimizing their own production processes.