The Steel Cable Tray Making Roll Forming Machine An Innovative Solution for Modern Infrastructure

In today's rapidly advancing industrial landscape, the demand for efficient and durable cable management solutions is paramount. Steel cable trays have emerged as a vital component in electrical infrastructure, providing support and protection for electrical cables in various settings, from industrial plants to commercial buildings. To meet the growing market demands, the steel cable tray making roll forming machine has become an essential piece of equipment for manufacturers.

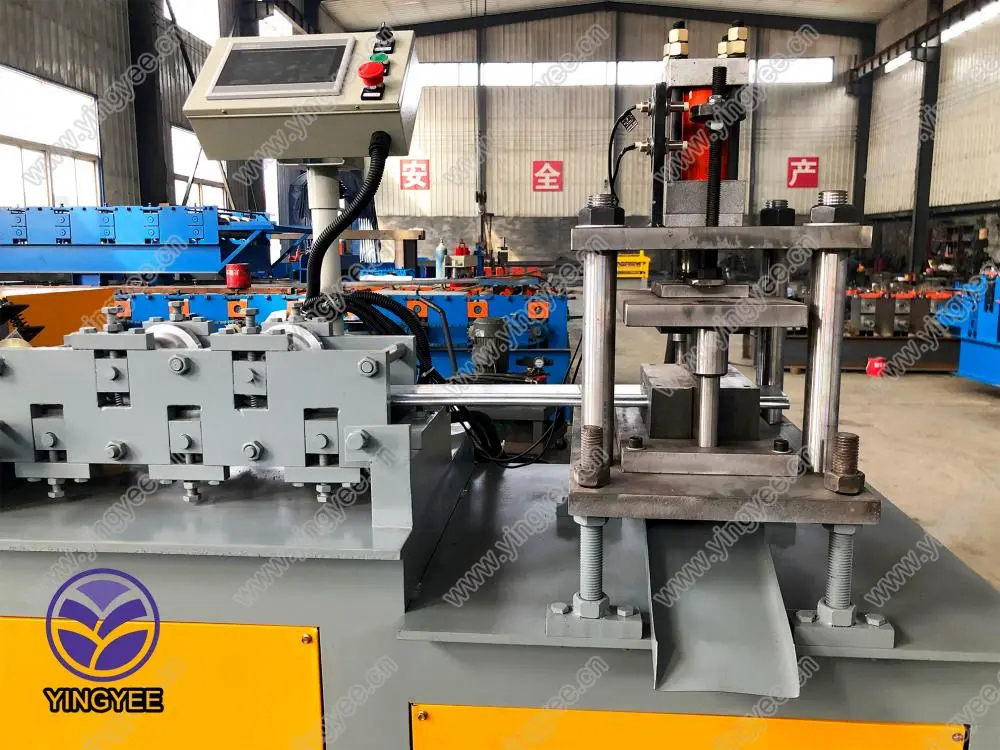

The roll forming machine is a specialized apparatus designed to convert flat steel sheets into intricate profiles through a continuous bending process. This method is particularly advantageous for producing steel cable trays, as it allows for high-volume production with consistent quality. Additionally, the flexibility of the roll forming process enables manufacturers to customize tray designs to meet specific requirements, such as size, thickness, and load capacity.

One of the key advantages of the steel cable tray making roll forming machine is its efficiency. The machine can produce a significant length of cable tray in a relatively short period, reducing labor costs and increasing output. This is crucial for manufacturers looking to maximize productivity while minimizing downtime. Furthermore, the precise nature of the roll forming process ensures that each tray maintains uniform dimensions, which is essential for installation and compatibility with existing systems.

Another notable benefit of using a roll forming machine for cable tray production is the reduction of material waste. The continuous feeding of steel sheets into the machine allows for a seamless transition from raw material to finished product, optimizing the use of steel and contributing to cost savings. Additionally, the strong and durable nature of steel ensures that the final products can withstand the rigors of various environmental conditions, making them suitable for both indoor and outdoor applications.

Operation of the steel cable tray making machine is user-friendly, typically featuring advanced controls and automation systems that facilitate the production process. Modern machines often include options for integrating additional features, such as perforation and welding, which can further enhance the functionality of the manufactured trays. With the ability to produce multiple designs and sizes with minimal setup time, manufacturers benefit from increased versatility and adaptability to market demands.

In terms of sustainability, the use of steel in cable tray production aligns well with eco-friendly practices. Steel is a recyclable material, and using it in cable tray manufacturing promotes responsible resource management. Additionally, the efficiency of the roll forming process contributes to lower energy consumption compared to other manufacturing methods.

In conclusion, the steel cable tray making roll forming machine represents a significant advancement in the production of cable management solutions. With its efficiency, versatility, and commitment to quality, this innovative equipment meets the demands of modern infrastructure while promoting sustainability. As industries continue to evolve, the role of roll forming machines in facilitating reliable and durable electrical management systems will undoubtedly grow, paving the way for a more organized and efficient future.