In the realm of modern construction and industrial manufacturing, the standing seam metal roll forming machine stands as a pivotal innovation. Known for transforming metal coils into structured panels, this machinery has revolutionized how roof and wall cladding systems are devised and installed. With years of meticulous engineering and application across various projects, its rising significance in construction cannot be overstated.

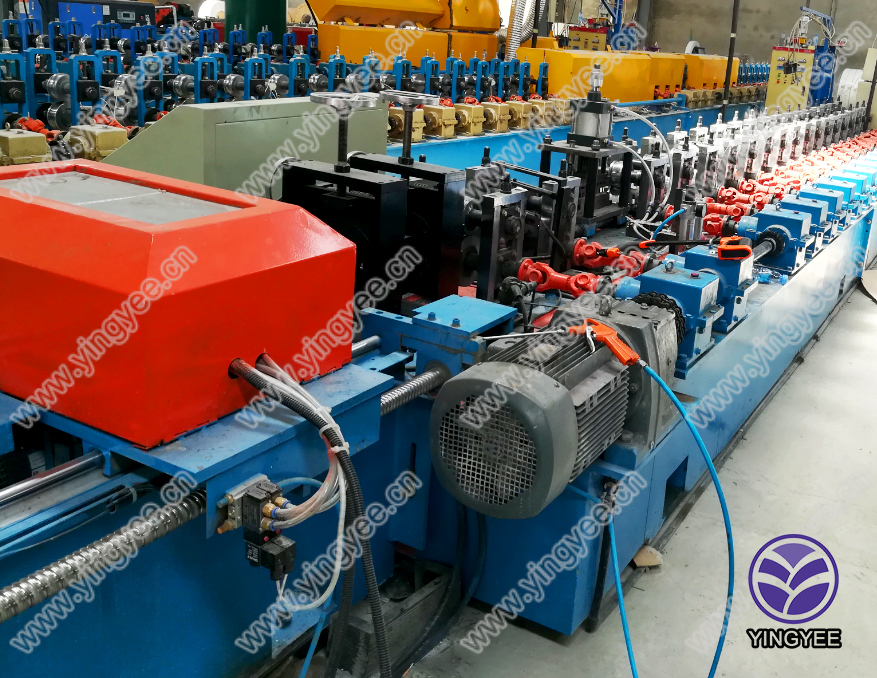

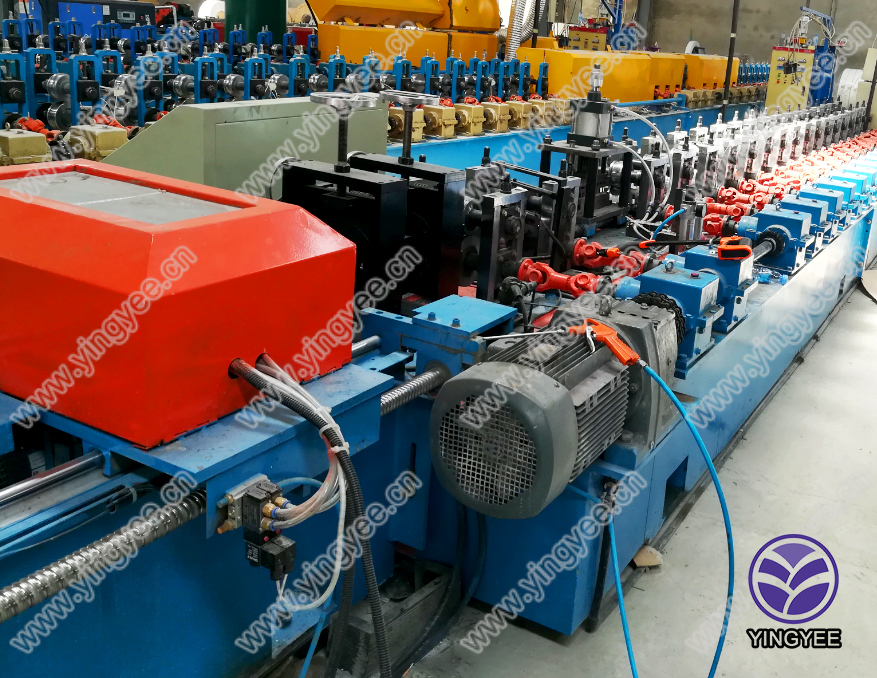

A standing seam metal roll forming machine operates with unmatched proficiency, offering versatility and precision. These machines are crafted to shape metal roofing materials, tailoring them to suit a plethora of architectural designs and structural requirements. The formation process involves passing flat metal sheets through a series of carefully aligned and calibrated rollers.

The outcome is a series of panels with continuous seams running from ridge to eaves.

From an expert perspective, the true strength of these machines lies in their customization capabilities. Not only do they permit adjustments in terms of panel width and seam height, but they also accommodate different metal types, including steel, aluminum, and copper. This kind of versatility is invaluable for contractors who must adapt to specific project requirements, ensuring both aesthetic appeal and functional longevity.

Technical prowess aside, the authoritative stance comes from recognizing the machine’s economic appeal. By investing in such technology, businesses can significantly curtail material waste and labor expenses. The precision of these machines minimizes human error, leading to flawless installations and reduced after-sales service or maintenance. Furthermore, the ability to fabricate panels onsite cuts transportation costs and mitigates potential damage during delivery.

standing seam metal roll forming machine

From a trustworthiness standpoint, renowned manufacturers ensure that each standing seam metal roll forming machine undergoes rigorous quality control processes. Understanding that the construction sector demands tools capable of enduring harsh climates and intensive usage, leading brands in the industry dedicate resources to innovation and rigorous testing. This commitment to quality guarantees durability, sustaining trust with contractors and architects worldwide.

Moreover, the real-world experience of using these machines elucidates their pivotal role in modern architecture. Professionals well-versed in deploying roll forming machines can attest to their operational efficacy and the consistent quality of panels produced. The seamless integration into the workflow not only expedites project timelines but also enhances the structural integrity of finished buildings.

The rise in demand for eco-friendly and energy-efficient construction materials dovetails with the capabilities of standing seam metal roll forming machines. Metal roofs, known for their energy-saving potential and recyclability, align perfectly well with green building initiatives. This harmony between environmental sustainability and advanced engineering further solidifies the machine’s standing in sustainable construction practices.

In conclusion, standing seam metal roll forming machines are not merely tools but vital components in the edifice of modern construction. They embody a confluence of precision engineering, economic efficiency, and sustainable building practices. As the construction industry continues to evolve, the role of such machinery in bridging the gap between traditional craftsmanship and future-ready solutions cannot be undermined. For stakeholders across the board, from machinists to architects, these machines represent a potent blend of reliability, efficiency, and innovation, ultimately reshaping the industry’s landscape.