Understanding Standing Seam Metal Roof Machines

In the realm of modern construction, standing seam metal roofs have emerged as a popular choice for both residential and commercial buildings. These roofs are characterized by their vertical seams that interlock and stand slightly above the roof plane, providing superior weather resistance and aesthetic appeal. The efficiency and precision of installing such roofs significantly depend on the technologies and machinery used, particularly standing seam metal roof machines.

Understanding Standing Seam Metal Roof Machines

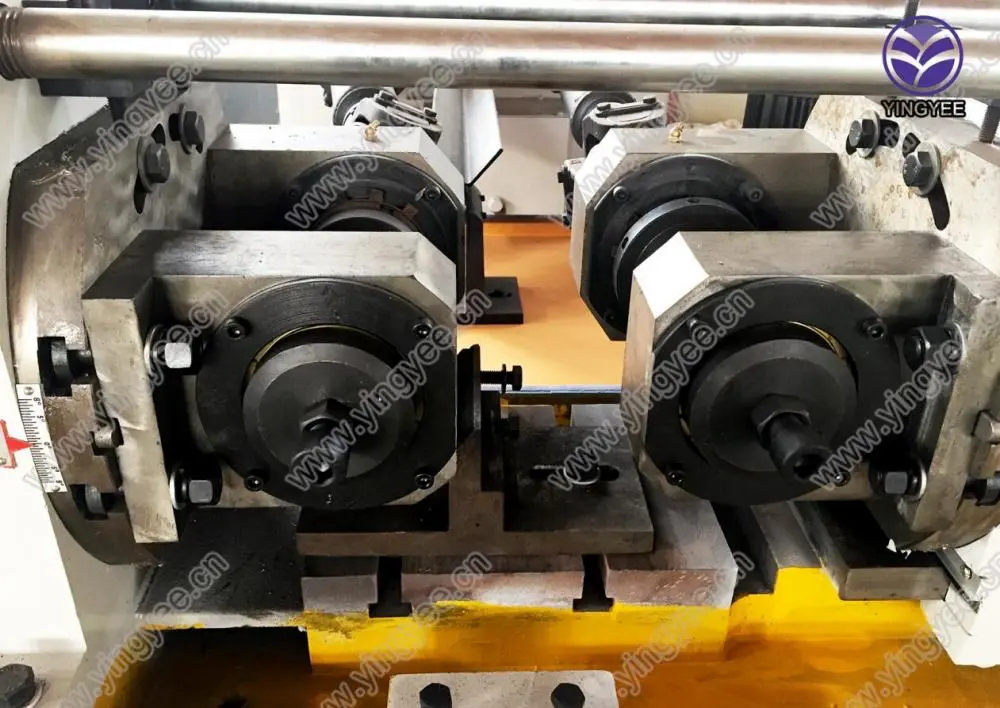

One of the primary advantages of using a standing seam metal roof machine is its ability to create custom panels that meet specific design requirements. These machines can handle various materials, including aluminum, steel, and copper, allowing for versatility in roofing options. Additionally, machines equipped with computer numerical control (CNC) technologies can produce panels with complex profiles and precise measurements, ensuring that each piece is tailored for the unique contours of a building.

Installation speed is another critical factor where these machines excel. Traditional roofing methods can be time-consuming and labor-intensive, often leading to extended project timelines. In contrast, standing seam metal roof machines can significantly reduce installation time. With the ability to manufacture panels on-site, contractors can immediately install them, minimizing delays associated with transportation and waiting for pre-fabricated materials. This efficiency is particularly beneficial for projects with tight schedules or adverse weather conditions.

Moreover, standing seam roofs are known for their durability and longevity. The interlocking seam design not only enhances the roof’s ability to withstand harsh weather conditions, such as heavy rain, snow, and high winds, but also contributes to lower maintenance costs over time. Using these machines ensures that the panels are produced with high standards, leading to fewer issues related to leaks or warping.

From an economic perspective, the initial investment in standing seam metal roof machines can be justified by the cost savings achieved through increased efficiency and reduced labor. Additionally, the long-term benefits of energy efficiency and low maintenance associated with standing seam roofs can appeal to environmentally conscious builders and homeowners alike.

In conclusion, standing seam metal roof machines have transformed the roofing industry by enhancing fabrication processes and installation speed. With the capability to produce durable, high-quality roofing panels tailored to specific needs, these machines play a vital role in modern construction practices. As the demand for energy-efficient and aesthetically pleasing roofs continues to rise, the importance of standing seam metal roof machines will undoubtedly grow, shaping the future of building design and construction.