Understanding Standing Seam Bending Tools An Essential for Metal Roofing

In the realm of modern roofing, the standing seam metal roof has carved a niche for itself due to its durability, weather resistance, and aesthetic appeal. One critical component in the installation of standing seam roofs is the bending tool, a specialized device designed to create the unique seams that hold the roofing panels together. This article aims to delve into the intricacies of standing seam bending tools, exploring their functions, types, and significance in the roofing industry.

What is a Standing Seam Roof?

Before discussing bending tools, it's essential to understand what a standing seam roof entails. A standing seam roof consists of vertical panels that are connected by raised seams, which are typically joined with mechanical clips or fasteners. This design prevents water accumulation and facilitates effective water runoff, making it particularly suitable for various climates. The aesthetic appeal and clean lines of standing seam roofs have made them a popular choice for both residential and commercial buildings.

The Role of Bending Tools

Bending tools for standing seam roofing are designed specifically to shape the edges of metal panels, allowing the seams to interlock securely. The bending process is crucial for ensuring that the panels fit together perfectly, preventing leaks and enhancing the overall structural integrity of the roof. Properly bent seams also contribute to the roof's visual appeal, with consistent seams providing a polished look.

Types of Bending Tools

Several types of bending tools are available for standing seam roofs, each with distinct features to suit various project requirements

1. Manual Benders These are handheld tools suitable for small projects or for roofing professionals who value portability. Manual benders are typically less expensive and can effectively bend metal up to a certain thickness. However, they require considerable effort and skill to produce consistent bends.

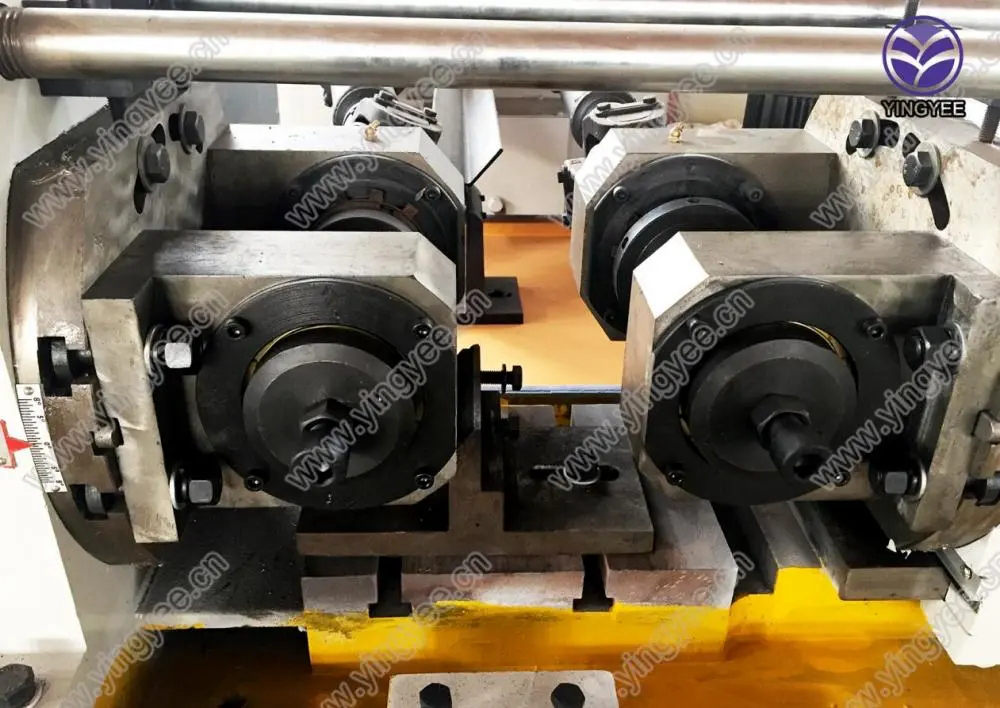

2. Electric Benders For larger projects or when precision is paramount, electric benders are the tool of choice. They offer consistent and accurate bends with less manual labor involved. Electric benders can handle thicker sheets of metal and are often used in professional settings.

3. Hydraulic Benders These tools utilize hydraulic pressure to bend larger sheets of metal with ease. Hydraulic benders are ideal for high-volume operations and are often used in commercial applications where speed and efficiency are critical.

4. Handheld Seamers Often used in conjunction with bending tools, handheld seamers create a tight seal at the seams, enhancing durability and water resistance. These tools help finish the seam after bending is complete.

Importance of Using the Right Bending Tool

Selecting the appropriate bending tool for the job is crucial for several reasons. Firstly, the right tool ensures that the seams are both aesthetically pleasing and functional, helping to prevent water leaks and prolonging the lifespan of the roof. Moreover, using the correct tool can significantly improve efficiency and reduce labor costs, making it a smart investment for contractors.

Conclusion

Standing seam bending tools are indispensable in the installation and maintenance of standing seam metal roofs. By understanding the different types of bending tools available and their respective applications, roofing professionals can ensure that they choose the right tool for their projects. In turn, this leads to improved quality, enhanced durability, and greater satisfaction for both contractors and homeowners. As the demand for metal roofing continues to rise, mastering the use of standing seam bending tools will be essential for anyone looking to thrive in this dynamic industry.