The Evolution and Significance of Stainless Steel Tube Mills

Stainless steel tube mills play a pivotal role in the manufacturing industry, providing essential components for a variety of applications ranging from automotive to construction. Over the years, these mills have evolved significantly, driven by technological advancements and increasing demand for durable and corrosion-resistant materials.

Stainless steel is known for its unique properties such as high strength, resistance to corrosion, and aesthetic appeal. This metal is particularly vital in industries where hygiene and cleanliness are paramount, like food processing, pharmaceuticals, and medical equipment. Stainless steel tube mills facilitate the production of tubes that meet stringent industry standards, ensuring that the final products maintain their integrity and performance under challenging conditions.

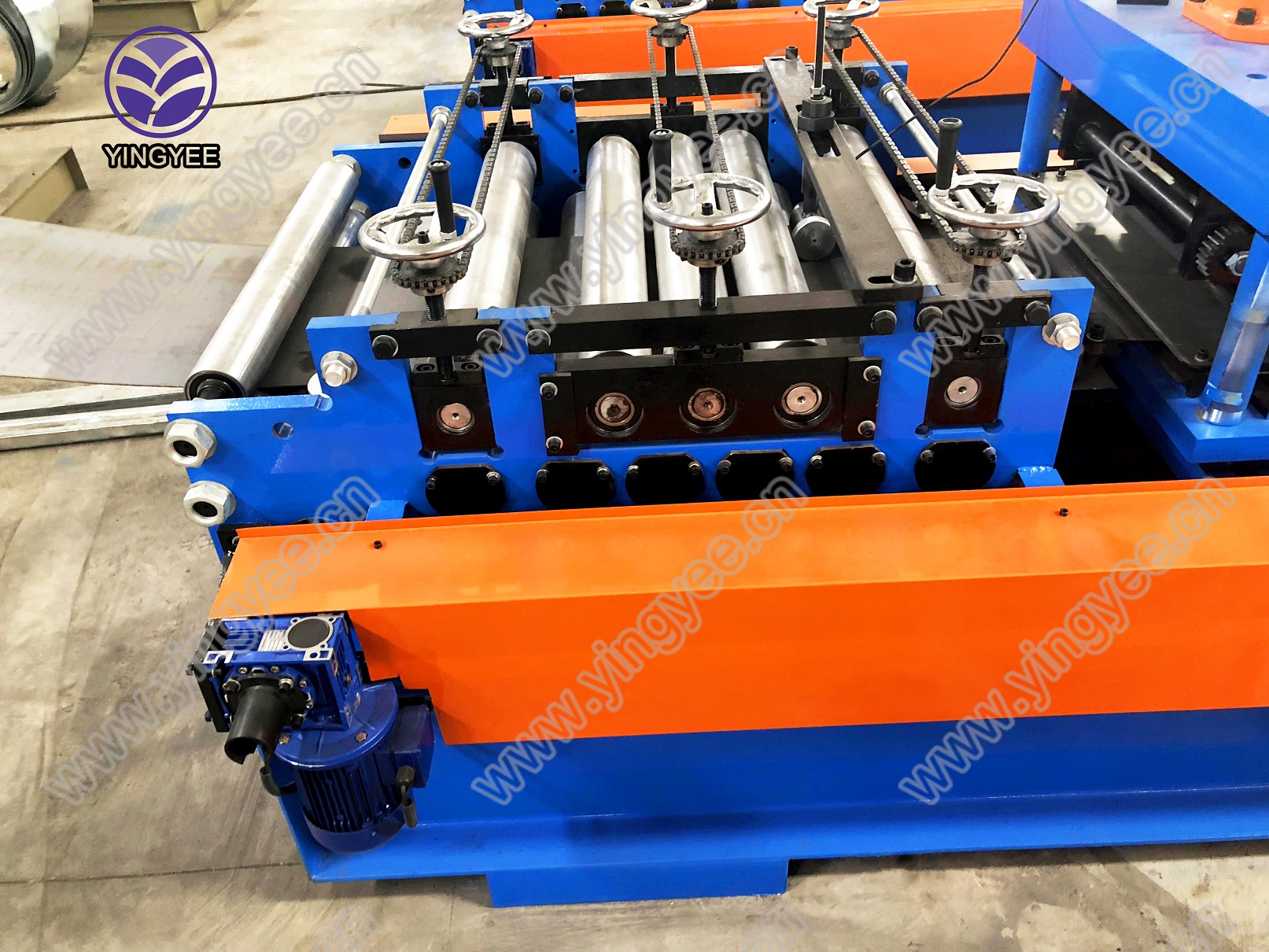

The process of manufacturing stainless steel tubes typically involves several stages, including the formulation of raw materials, welding, and finishing. The initial step begins with the selection of high-quality stainless steel alloys, which are then processed into sheets or strips. These sheets are shaped into tubes using advanced techniques such as welding or seamless methods. The welding process, which includes techniques like TIG and MIG welding, ensures that the seams are strong and can withstand internal pressures.

Modern stainless steel tube mills employ state-of-the-art technology, including CNC machinery and automated systems, to enhance efficiency and precision. These technological advances not only improve production rates but also reduce material waste, making the process more eco-friendly. Furthermore, the rise of digitalization and Industry 4.0 has led to smarter manufacturing processes, where data analytics and IoT devices are used to monitor production in real-time, ensuring quality control and minimizing downtime.

The global market for stainless steel tubes continues to expand, with increasing applications in sectors such as energy, automotive, and construction. For instance, the demand for stainless steel tubes in renewable energy projects, like wind turbines and solar panels, underscores their importance in supporting sustainable initiatives.

As the industry progresses, stainless steel tube mills are expected to innovate further, exploring new alloys and manufacturing techniques. The focus on sustainability and reducing carbon footprints will also shape future developments, as manufacturers seek to align with global environmental goals.

In conclusion, stainless steel tube mills are integral to modern manufacturing, providing essential products that meet diverse industrial needs. As technology advances and markets evolve, these mills will continue to play a crucial role in ensuring the availability of high-quality, reliable stainless steel tubes for various applications.