The Stainless Steel Tube Mill Revolutionizing the Manufacturing Process

In the modern industrial landscape, the efficiency of manufacturing processes often dictates the overall success of the production chain. One of the significant advancements in this sector is the development of the stainless steel tube mill. This specialized machinery has revolutionized the way stainless steel tubes are produced, catering to a diverse range of industries, including construction, automotive, healthcare, and aerospace.

Understanding Stainless Steel Tube Production

The process of manufacturing stainless steel tubes begins with the selection of high-quality raw materials. Stainless steel, known for its corrosion resistance and strength, is the preferred choice. The production process employs several stages, including the slitting of stainless steel coils, forming, welding, and finishing, each requiring precision and expertise.

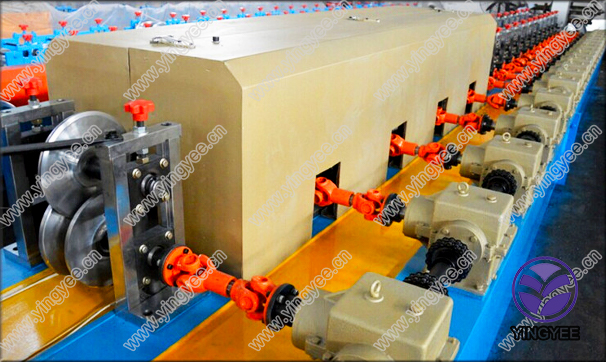

Stainless steel tube mills are designed to handle various shapes and sizes of tubing, with the ability to produce both seamless and welded tubes. The distinction lies in the manufacturing techniques employed. Seamless tubes are made from a solid round steel billet, which is heated and pushed through a die to create the desired shape. Conversely, welded tubes are formed by rolling flat rolled stainless steel material and welding the edges together, ensuring a continuous product.

The Importance of Efficiency

A key advantage of stainless steel tube mills is their ability to enhance production efficiency. The integration of advanced technology, such as automated systems and computer numerical control (CNC), ensures that the production process is streamlined. Automated settings allow for precise measurements and consistent quality, reducing the likelihood of defects and wastage.

Moreover, tube mills can operate at high speeds while maintaining a high degree of accuracy. This not only increases output but also decreases the manufacturing time, allowing companies to meet growing demand without compromising quality. The level of automation also minimizes the need for manual labor, reducing operational costs and improving worker safety.

Versatility and Customization

Stainless steel tube mills are renowned for their versatility. They can produce a wide array of tube shapes, including round, square, and rectangular tubes, making them suitable for a vast range of applications. Additionally, manufacturers can customize specifications, such as wall thickness, length, and surface finish, to meet the unique requirements of various industries.

For instance, in the healthcare sector, the demand for high-purity stainless steel tubing is on the rise, particularly for applications involving medical devices and surgical instruments. The tube mills can be adjusted to fabricate products that meet stringent hygienic standards while ensuring structural integrity.

Environmental Impact and Sustainability

Another critical aspect of the stainless steel tube mill industry is its commitment to sustainability. Stainless steel is infinitely recyclable, which means that the production of stainless steel tubes can significantly reduce waste. Many modern tube mills incorporate sustainability practices, such as utilizing scrap metal and energy-efficient technologies, which not only lower carbon footprints but also promote responsible manufacturing practices.

Furthermore, the durability of stainless steel enhances its sustainability profile. Products made from stainless steel tubes have longer lifespans, reducing the need for replacements and consequently conserving resources.

Future Trends in Stainless Steel Tube Production

As technological advancements continue to evolve, the stainless steel tube mill industry is embracing innovations such as artificial intelligence (AI) and the Internet of Things (IoT). These technologies offer real-time data and analytics, enabling manufacturers to optimize their processes, predict maintenance needs, and enhance product quality.

Additionally, the demand for lightweight yet sturdy materials is driving research into advanced materials and composites, which may influence the future design and functionality of stainless steel tubing. The industry can anticipate more eco-friendly manufacturing methods and a continued emphasis on quality and precision.

Conclusion

The stainless steel tube mill stands as a testament to modern engineering and manufacturing prowess. With its ability to produce high-quality products efficiently, it plays a vital role in various industries. As the sectors it serves continue to grow and evolve, so too will the technologies and processes behind stainless steel tube mills. Embracing innovation and sustainability will ensure that this industry remains a cornerstone of modern manufacturing for years to come.