Stainless Steel Pipe Making Machine Revolutionizing Modern Manufacturing

In the realm of manufacturing, the demand for high-quality, durable materials has never been higher. One of the unsung heroes in this industrial revolution is the stainless steel pipe making machine. These sophisticated machines play a crucial role in producing pipes that are essential in various sectors, including construction, automotive, aerospace, and pharmaceuticals. In this article, we will explore the importance of stainless steel pipe making machines, their operational principles, and the advantages they offer to the manufacturing process.

The Importance of Stainless Steel Pipes

Stainless steel pipes are favored for their exceptional strength, corrosion resistance, and aesthetic appeal. These qualities make them ideal for applications in harsh environments, such as chemical processing plants or marine applications. Additionally, their longevity and low maintenance requirements contribute to their economic viability. As industries continue to expand, the need for reliable sources of high-quality stainless steel pipes has surged, ushering in a new era of manufacturing capabilities facilitated by advanced machinery.

Operational Principles of Stainless Steel Pipe Making Machines

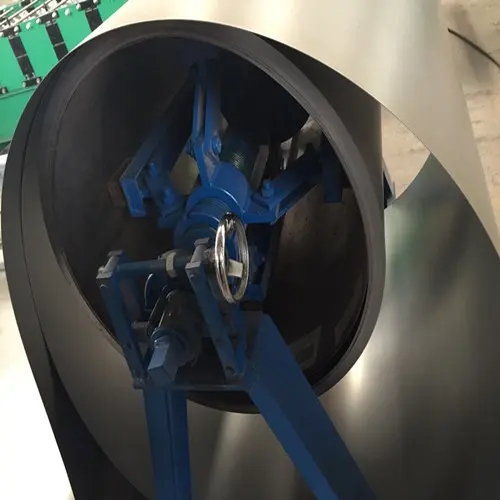

Stainless steel pipe making machines operate through a combination of processes, including slitting, forming, welding, and finishing. The process typically begins with a coil of stainless steel sheet, which is slit to the desired width. This slit strip is then fed into a series of rollers that shape it into a cylindrical form.

The critical stage of welding follows, where the edges of the strip are joined together. Modern machines employ various welding techniques, such as high-frequency induction welding or TIG (Tungsten Inert Gas) welding. These methods ensure a strong bond while minimizing heat input to maintain the integrity of the stainless steel.

Once welded, the pipes undergo several finishing operations, including deburring, polishing, and cutting to length. These finishes are vital not only for aesthetic purposes but also for functional requirements, such as ensuring a smooth internal surface for fluid flow or meeting specific regulatory standards.

Advantages of Using Stainless Steel Pipe Making Machines

1. Efficiency and Speed The automation and advanced technology incorporated into modern stainless steel pipe making machines significantly enhance manufacturing efficiency. These machines can produce large quantities of pipes in a relatively short time, thereby reducing production lead times and costs.

2. Precision and Quality Control With integrated sensors and automated control systems, these machines ensure that the pipes produced meet stringent specifications. This precision is critical for industries where tolerances are tight, such as in aerospace or medical applications.

3. Versatility Stainless steel pipe making machines can produce pipes in various sizes and shapes, accommodating different industry standards and customer requirements. This flexibility is essential as it allows manufacturers to diversify their offerings without needing multiple machines.

4. Minimal Waste Modern machines are designed with waste reduction in mind. They optimize material usage during the cutting and forming processes, ensuring that excess material is minimized, thus lowering overall production costs.

5. Sustainability As the world shifts towards greener practices, stainless steel pipe making machines contribute to sustainability efforts. Stainless steel itself is recyclable, and these machines often incorporate energy-efficient technologies that reduce the carbon footprint of the manufacturing process.

Conclusion

In conclusion, stainless steel pipe making machines are a pivotal component of modern manufacturing. Their advanced functionalities not only enhance efficiency and quality but also ensure that industries can meet the increasing demand for high-quality stainless steel pipes. As technology continues to evolve, so too will the capabilities of these machines, paving the way for even greater innovation in the manufacturing sector.