In the rapidly evolving landscape of industrial manufacturing, the square and round downspout roll forming machine stands as a paragon of engineering excellence. As an essential tool in the production of building components, this machine exemplifies precision, efficiency, and innovation pertinent to today's construction demands. This article explores the exceptional qualities and technical nuances of the square/round downspout roll forming machine, offering insights that highlight its pivotal role.

The square and round downspout roll forming machine epitomizes a fusion of advanced technology and robust engineering. Designed to produce precisely shaped downspouts from metal coils, it is engineered to meet the diverse needs of modern architecture. These machines are essential for creating functional and aesthetically pleasing drainage systems, which complement the design of both residential and commercial structures. The ability to produce both square and round downspouts with a single unit is a testament to its versatility, helping manufacturers respond swiftly to changing market demands.

Armed with cutting-edge technology, these machines are built with state-of-the-art PLC systems offering unmatched operational control. Operators can easily adjust parameters, ensuring high precision in the roll forming process. This level of automation not only enhances productivity but also ensures consistency in product quality, a critical factor in the competitive manufacturing sector. The robust construction of the machine ensures minimal downtime, providing reliable performance that manufacturers can count on to meet their production quotas.

The expertise required to operate and maintain these machines underscores their complexity and sophistication. It is recommended that companies invest in trained personnel who understand the intricacies of roll forming technology. Expert operators can maximize machine performance, ensuring that each downspout meets exact specifications. Given the substantial investment, the long-term returns on maintaining optimal operational efficiency are significant.

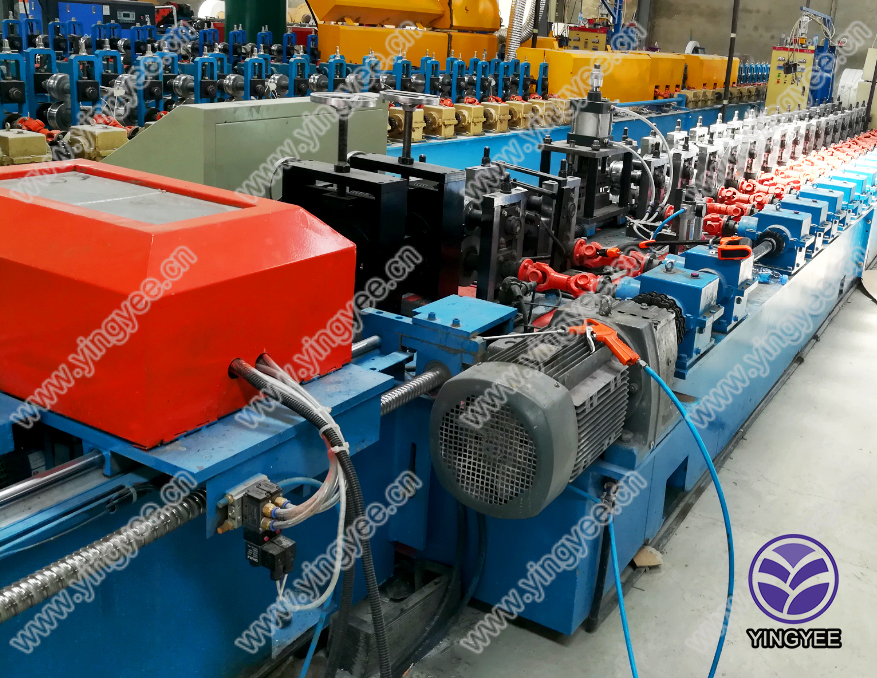

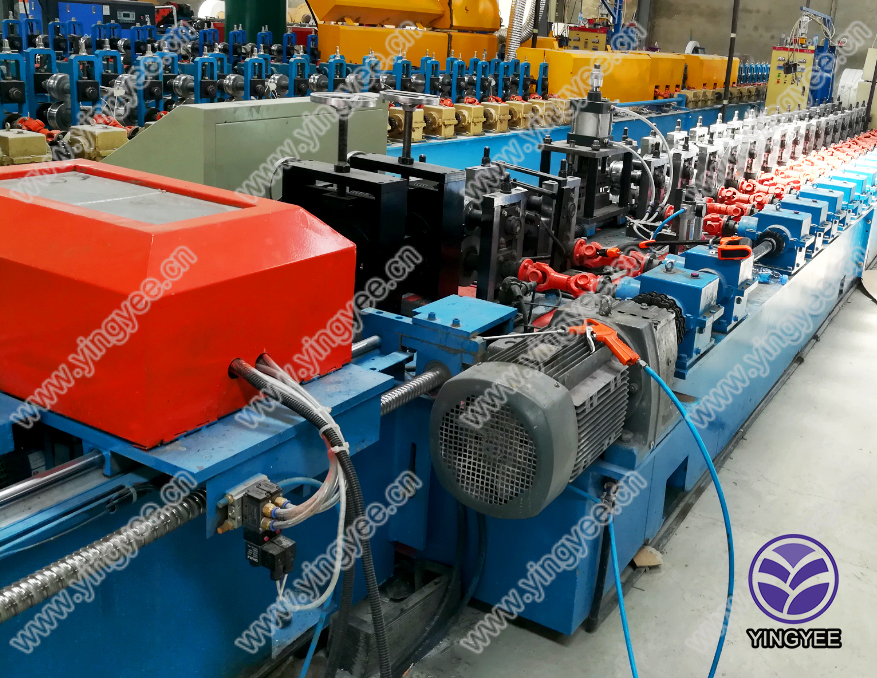

square/round downspout roll forming machine

Authoritativeness is inherent in the design and functionality of these machines. Developed by leading manufacturers worldwide, these roll forming systems are backed by years of research and development. The integration of research-driven innovations ensures that the machines remain at the forefront of industry standards. Moreover, the trustworthiness of these machines is reflected in their capacity to deliver consistent performance, bolstered by comprehensive warranty and support services from manufacturers.

In terms of real-world application, the square and round downspout roll forming machine is vital to sectors focusing on sustainable building practices. The precision it offers ensures downspouts that efficiently channel water, reducing potential damage to building foundations and enhancing the longevity of structures. This environmental consideration is a crucial facet in modern construction, where sustainability and durability go hand in hand.

Thus, for businesses aiming to lead in the production of metallic downspouts, investing in a square/round downspout roll forming machine is a strategic imperative. These machines not only streamline production but also enhance the quality and competitiveness of their products. Employing the expertise necessary to leverage this equipment effectively can propel a manufacturer to new heights, ensuring they remain a step ahead in a demanding market.

In conclusion, the square and round downspout roll forming machine represents a critical innovation in the realm of building component manufacturing. Its integration into production lines signifies a commitment to excellence, sustainability, and technological advancement. As industries continue to evolve, those that harness the potential of such cutting-edge equipment will undoubtedly secure their position at the vanguard of industrial progress.