Understanding Square and Round Downspout Roll Forming Machines

In the modern construction and building industry, the efficiency and precision of manufacturing components are key factors that can significantly influence project timelines and costs. One essential machine facilitating this is the square and round downspout roll forming machine. This equipment is specially designed to produce downspouts used in drainage systems, ensuring both functionality and aesthetic appeal.

What is a Downspout?

Before delving into the specifics of roll forming machines, it's crucial to understand what downspouts are. Downspouts are vertical pipes that direct rainwater from gutters down to the ground or drainage system, preventing water damage to buildings by managing the flow of rainwater. Their design can be either square or round, catering to different architectural styles and drainage requirements.

The Role of Roll Forming Machines

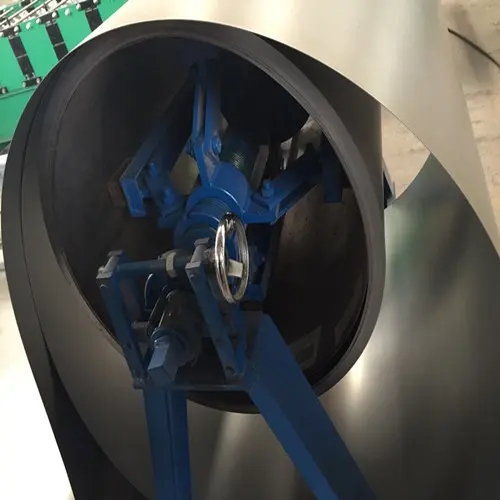

Roll forming machines are critical in the mass production of various metal components. These machines utilize continuous bending processes to create complex shapes from metal strips. The square and round downspout roll forming machines transform flat metal coils into precisely shaped downspouts quickly and efficiently.

Features of Square and Round Downspout Roll Forming Machines

1. Versatility One of the standout features of these machines is their ability to produce both square and round downspouts. This versatility means manufacturers can cater to various client specifications without needing multiple machines.

2. High Precision Modern roll forming machines are equipped with advanced technology that ensures high precision in the dimensions and shapes produced. This accuracy is crucial in ensuring that downspouts fit seamlessly into existing drainage systems.

3. Efficiency Roll forming machines can produce large quantities of downspouts in a relatively short time. This efficiency not only boosts productivity but also reduces labor costs associated with the manufacturing process.

4. Durability and Quality Most roll forming machines work with high-quality steel or aluminum, resulting in sturdy downspouts that can withstand harsh weather conditions. The machines often include a strict quality control process to ensure the final product meets industry standards.

5. Customizability Many manufacturers offer custom options where clients can specify particular dimensions, materials, and finishes. This adaptability is essential for meeting the diverse needs of construction projects.

Applications in Construction

The downspouts produced by roll forming machines are used in various construction applications. They are integral to residential homes, commercial buildings, and industrial facilities. Well-designed downspouts help manage water runoff effectively, protecting properties from water-related problems such as erosion, mold, and foundation damage.

Conclusion

The square and round downspout roll forming machine exemplifies the advancements in manufacturing technology within the construction industry. By enabling the production of high-quality, precise, and efficient downspouts, these machines play a vital role in modern building practices. As architects and builders continue to seek both functionality and aesthetics in design, the importance of efficient manufacturing processes like roll forming will only continue to grow. Investing in such technology will not only enhance operational efficiency but also contribute to the overall quality and longevity of construction projects.