Understanding Square Pipe Roll Forming Machines

In the realm of modern manufacturing, the square pipe roll forming machine has emerged as a pivotal piece of equipment. This specialized machinery is designed to produce square pipes from metal sheets, offering a streamlined and efficient process that has transformed how structural elements are fabricated. In this article, we delve into the functionality, advantages, and applications of square pipe roll forming machines.

What is a Square Pipe Roll Forming Machine?

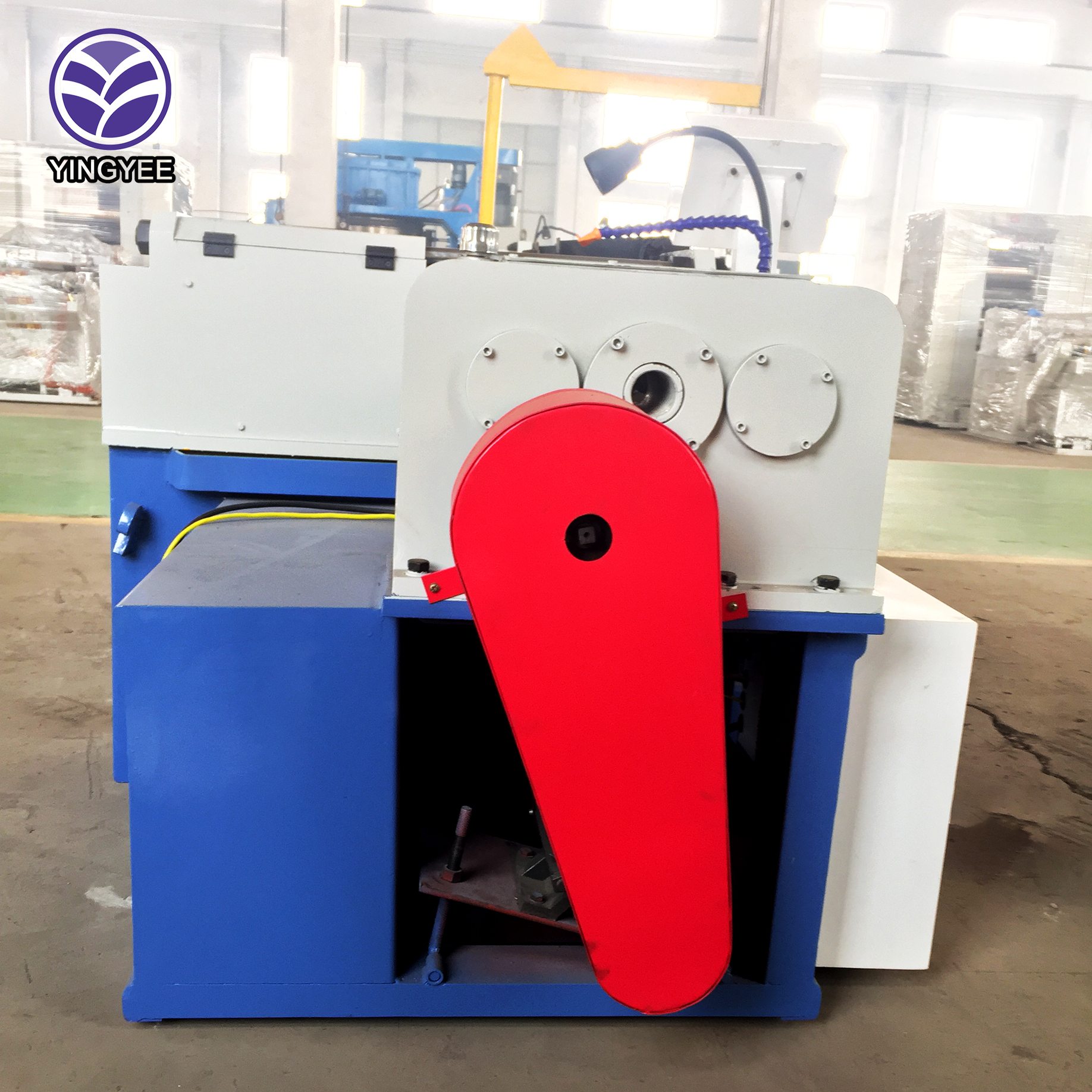

A square pipe roll forming machine is a type of machinery that continuously shapes metal sheets into square or rectangular pipes. The process begins with feeding a flat metal sheet into the machine, where it is gradually and precisely formed through a series of rollers. Each roller is designed to bend the metal at specific angles, ultimately leading to the final shape of the square pipe. Once the desired shape is achieved, the edges of the pipe are typically welded together to ensure structural integrity.

Key Features and Components

Square pipe roll forming machines typically consist of several key components

1. Feeding Mechanism This part of the machine ensures the metal sheet is fed accurately into the roll forming section. Proper alignment is crucial to maintaining the quality of the final product.

2. Roller System The heart of the machine, the roller system features multiple rollers that progressively bend the metal sheet into the desired shape. The arrangement and design of these rollers are essential for achieving the correct dimensions and tolerances.

3. Welding Unit After the pipe has been formed, a welding unit is employed to secure the edges of the pipe, transforming it into a fully functional square pipe.

4. Cutting Mechanism The cutting unit detaches the finished pipe from the continuous roll, allowing it to be collected for further processing or shipping.

Advantages of Using Square Pipe Roll Forming Machines

1. Efficiency and Speed One of the most significant advantages of roll forming machines is their ability to produce square pipes rapidly. The continuous nature of the process allows for high-volume production, making it an ideal choice for manufacturers needing large quantities of pipe.

2. Precision Roll forming machines are designed for high precision. The use of advanced technologies ensures that the pipes produced have consistent dimensions and high-quality finishes, which is crucial for structural applications.

3. Material Utilization These machines can effectively utilize materials with minimal waste. The process optimally shapes the metal sheets without generating excessive scrap, contributing to cost efficiency and sustainability.

4. Versatility Square pipe roll forming machines can handle various materials, including steel, aluminum, and other alloys. This versatility allows manufacturers to produce a wide range of products for different industries.

Applications of Square Pipes

Square pipes are widely used across various industries due to their strength and adaptability. Common applications include

- Construction Square pipes are used in building frameworks, railings, and support structures owing to their robust nature.

- Automotive In the automotive industry, square pipes are often used in the manufacturing of chassis and other structural components.

- Furniture These pipes are also popular in furniture design, providing a modern aesthetic while maintaining durability.

- Agricultural Equipment Square pipes find applications in agricultural machinery and structures, aiding in the construction of barns, sheds, and other facilities.

Conclusion

In conclusion, square pipe roll forming machines play an integral role in the manufacturing landscape. Their efficiency, precision, and versatility make them an invaluable asset for producers of square pipes, catering to diverse industries. As manufacturing technologies continue to advance, the role of such machines will only grow, paving the way for innovative applications and enhanced production capabilities. Embracing these machines not only improves operational efficiency but also contributes significantly to the overall quality of the products manufactured.