The Evolution and Importance of Square Pipe Making Machines

In the dynamic world of manufacturing, square pipe making machines have become vital components for numerous industries. These machines have transformed the way square pipes are produced, ensuring higher efficiency, precision, and quality in the final product. Understanding the functioning, applications, and benefits of square pipe making machines sheds light on their crucial role in modern manufacturing processes.

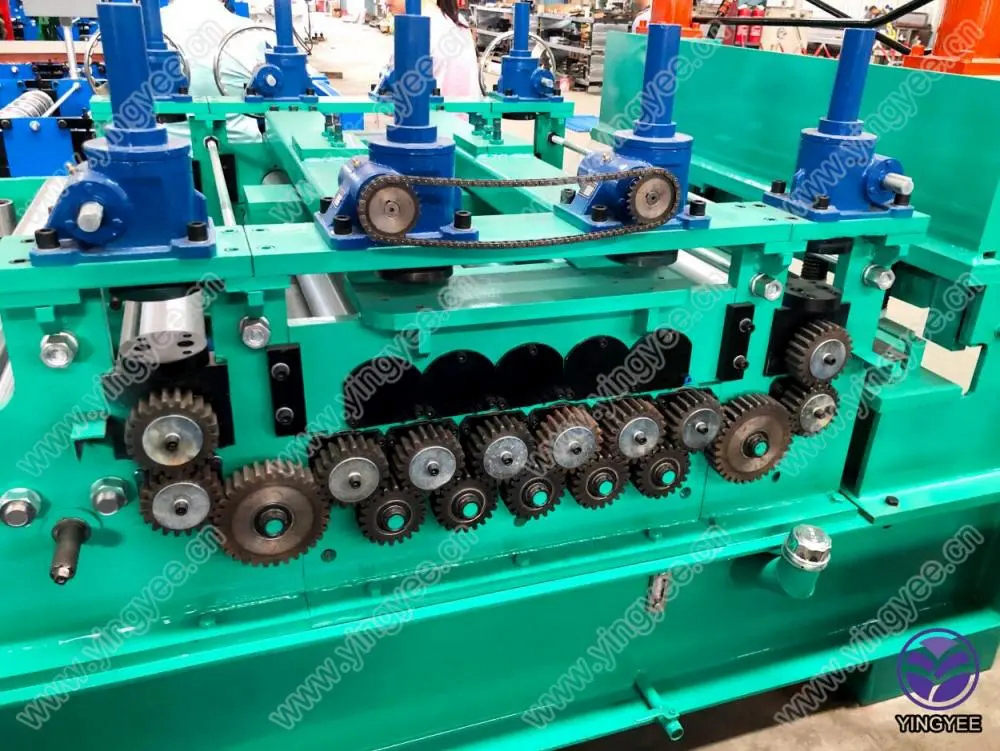

Understanding Square Pipe Making Machines

A square pipe making machine is engineered to produce square-sectional pipes from raw materials, typically steel or stainless steel. The conventional process involves feeding flat steel strips into the machine, which then undergoes various stages of forming, welding, and cutting to produce the final square pipe product. Key processes involved include de-coiling, slitting, forming, welding, and trimming. Advanced models incorporate technologies like computerized controls and automation, enabling precise adjustments and significantly minimizing production errors.

Applications of Square Pipes

Square pipes are widely used across multiple sectors, ranging from construction and infrastructure to automotive and furniture manufacturing. Their structural integrity and uniform shape make them ideal for applications requiring robust strength, such as building frameworks, scaffolding, and handrails. In automotive manufacturing, square pipes serve as critical components for vehicle frames and support structures, contributing to the overall safety and durability of automobiles.

The furniture industry also leverages square pipes for various applications. From the structures of tables and chairs to decorative elements, the aesthetic appeal combined with the strength of square pipes makes them a favored choice among designers. Additionally, they find applications in HVAC systems, electrical conduits, and plumbing, showcasing their versatility across different domains.

Benefits of Square Pipe Making Machines

One of the foremost advantages of square pipe making machines is their impressive efficiency. Automation and advanced technology have eradicated many manual steps in the production process, leading to higher output rates. This increase in productivity allows manufacturers to meet high demand while optimizing resource utilization.

Moreover, the accuracy of these machines ensures consistent dimensions and quality in finished products. This precision is critical, especially in industries where exact specifications are mandatory for safety and performance standards. Manufacturers can reduce waste and rework thanks to the uniformity achieved in production, translating into cost savings in materials and labor.

Environmental considerations also play a role in the relevance of square pipe making machines. Many modern machines utilize energy-efficient technologies and are designed to minimize material waste. By optimizing the production process, companies can reduce their carbon footprint, aligning with global sustainability goals.

Future Trends in Square Pipe Manufacturing

As technology continues to evolve, so too will the square pipe making machines. Innovations such as Industry 4.0, where interconnected machinery and data analytics drive efficiencies, are set to redefine manufacturing norms. Smart machines equipped with IoT capabilities can monitor production processes in real time, leading to better decision-making and predictive maintenance, which minimizes downtime.

Furthermore, the trend towards lightweight materials will influence the development of square pipe making machines to accommodate new materials without compromising strength. Manufacturers will need to adapt to these changes to maintain their competitive edge in the market.

Conclusion

In summary, square pipe making machines play an integral role in an array of industries, thanks to their ability to produce strong, high-quality pipes efficiently. With their capabilities set to evolve with technological advancements, these machines will remain key players in ensuring that manufacturing meets the growing demands of modern society. As industries continue to innovate, square pipe making machines will adapt, contributing to a sustainable and efficient future in manufacturing.