Square downpipe roll forming machines have carved a niche in the metal forming industry with their precision and efficiency. These machines are instrumental in shaping square downpipes, an essential component in modern construction for efficient water drainage systems. With technological advancements, manufacturers have refined these machines to meet the growing demands of the market. This article delves into the core features, benefits, and insights based on real-world experience with square downpipe roll forming machines, showcasing their indispensable role in today's manufacturing landscape.

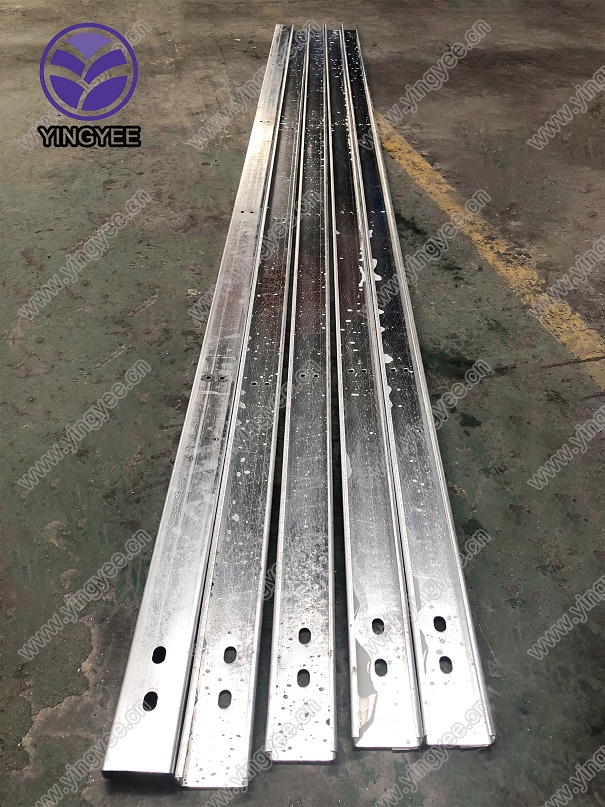

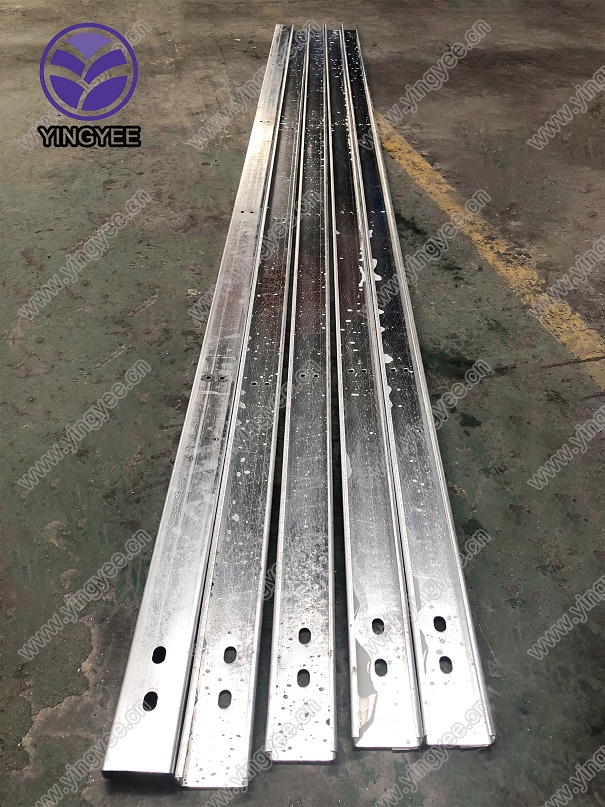

Square downpipe roll forming machines stand out due to their capability to produce uniform and high-quality downpipes consistently. The precision in the forming process ensures that each downpipe meets the specifications required for optimal performance. This precision is achieved through advanced control systems and robust roller designs that seamlessly shape the metal sheets into square downpipes. For manufacturers, this means reduced wastage and a higher yield of usable product, which directly correlates to increased profitability.

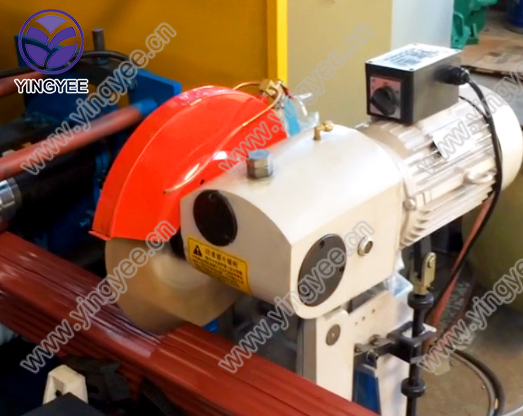

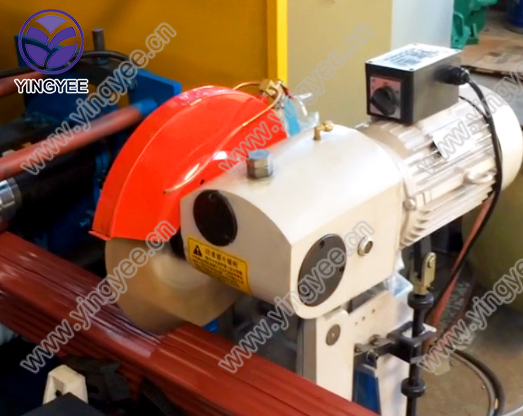

From an expert standpoint, the expertise infused in the design of these machines cannot be overstated. They incorporate cutting-edge technology such as Computer Numerical Control (CNC), which allows for high precision and flexibility in operations. Operators can adjust parameters with ease, catering to different sizes and thicknesses of metal sheets. The adaptability of these machines significantly reduces downtime and enhances productivity—a key aspect influencing the purchasing decision for manufacturers globally.

Authoritativeness within this domain comes from the integration of international standards and guidelines in the machine design and process. Leading manufacturers ensure their machines comply with various safety and quality standards, which are crucial for maintaining credibility and trust with users. Furthermore, many manufacturers provide certifications and regular updates to keep up with technological progress and maintain alignment with industry best practices. This adherence to high standards not only assures quality but also enhances the trustworthiness of the machines in customer operations.

square downpipe roll forming machine

The trustworthiness of square downpipe roll forming machines is further affirmed by their long-standing performance in diverse industrial settings. Users have reported significant improvements in production efficiency and consistency after integrating these machines into their operations. The reliability of the technology is backed by extensive testing and years of field usage, providing potential buyers with confidence in their investment. Additionally, comprehensive warranties and after-sales support offered by reputable manufacturers further underline the commitment to customer satisfaction and operational excellence.

Customer testimonials and case studies present compelling evidence of the efficacy of square downpipe roll forming machines. In practice, users have highlighted the ease of operation and maintenance, stemming from intuitive machine interfaces and robust build quality. This user-friendly nature is essential in reducing operator error and ensuring continuous operation. Real-life experiences demonstrate how businesses have scaled their production capabilities while maintaining stringent quality controls, thus maximizing their return on investment.

In conclusion, square downpipe roll forming machines prove to be a critical asset in the metal forming industry, embodying a perfect blend of expertise, authority, and trustworthiness. Their design reflects thoughtful engineering and an acute understanding of industrial requirements. As the demand for efficient drainage solutions grows, these machines will inevitably continue to play a pivotal role in meeting both current and future challenges in production dynamics. For businesses seeking to optimize their operational efficiency and product quality, embracing the capabilities of square downpipe roll forming machines is a strategic choice poised for enduring returns.