Square Downpipe Roll Forming Machine An Overview

The square downpipe roll forming machine is an essential piece of equipment in modern construction and manufacturing. This innovative machine is designed to produce square downpipes, which are vital components in drainage systems, roofing, and various architectural applications. Utilizing advanced roll forming technology, these machines ensure high precision, efficiency, and durability in the manufacturing process.

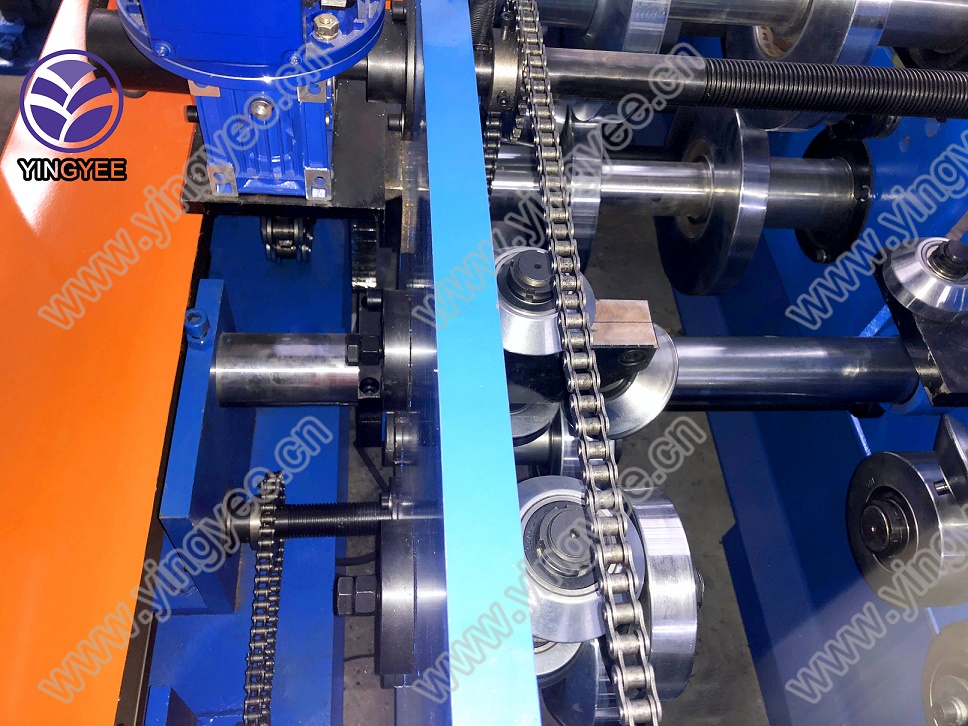

The production process begins with the feeding of flat metal sheets, typically made of galvanized steel, aluminum, or other suitable materials, into the machine. As the sheets pass through a series of rollers, they are gradually shaped into the desired square profile. The roll forming process is continuous, allowing for the creation of long lengths of downpipe with minimal waste. This is particularly advantageous for manufacturers looking to optimize their production lines and reduce material costs.

One of the key benefits of using a square downpipe roll forming machine is its ability to produce customizable products. Manufacturers can easily adjust the settings and rollers to create various sizes and thicknesses of downpipes, catering to specific client needs. This flexibility not only enhances product variety but also allows for rapid prototyping and quicker response times to market demands.

Moreover, the square downpipe roll forming machine integrates modern technology such as PLC control systems, which facilitate automation and improve operational efficiency. These systems enable precise adjustments to the roll formation process, ensuring consistency in product dimensions and reducing human error. Operators can monitor the production line in real time, making adjustments as necessary to maintain optimal performance and quality standards.

Another significant advantage of these machines is their low maintenance requirements. Designed for durability, the roll forming components are built to withstand prolonged usage without frequent breakdowns. This reliability translates to higher uptime and decreased production delays, making the investment in this machinery worthwhile for manufacturers.

In conclusion, the square downpipe roll forming machine is a vital asset in the manufacturing of high-quality downpipes. With its ability to produce customizable products, integrate advanced technology, and minimize maintenance needs, it addresses the challenges faced by modern manufacturers. As the construction and architectural industries continue to evolve, the importance of such machinery will undoubtedly grow, making it essential for companies to consider investing in this innovative technology.