Understanding Square Downpipe Roll Forming Machines

In the world of metal fabrication and construction, efficiency and precision are paramount. Among the most innovative technologies that have emerged to meet these demands is the square downpipe roll forming machine. Designed for producing square downpipes in various sizes, this equipment has revolutionized the way contractors and manufacturers approach their projects.

What is a Square Downpipe Roll Forming Machine?

A square downpipe roll forming machine is a specialized piece of machinery used to create square and rectangular downpipes from metal sheets or coils. The process involves feeding flat metal strips into the machine, which then continuously bends and shapes the metal into the desired profile through a series of rollers. This process is known as roll forming, and it allows for a high degree of precision and repeatability in the production of downpipes.

Key Components of the Machine

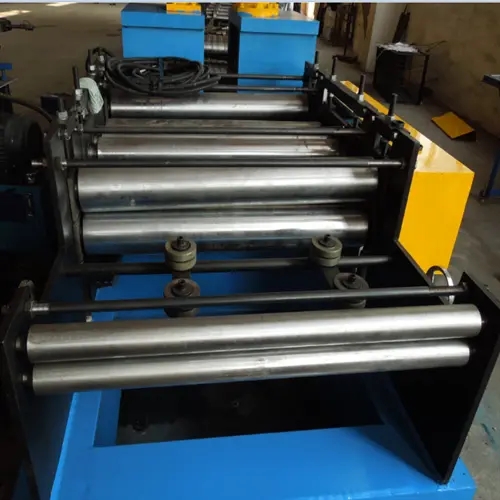

The typical roll forming machine consists of several key components

1. Rollers The heart of the machine, rollers shape the metal as it passes through. Each roller is designed to perform a specific bending operation, allowing for smooth and consistent shaping of the material.

2. Roller Stands These are the structures that hold the rollers in place. They ensure that the rollers maintain proper alignment and provide stability during the forming process.

3. Material Feed System This component regulates the feed of the metal strip into the machine, ensuring that it is fed at the correct speed and tension.

4. Cutting Unit Once the desired length of the downpipe is formed, the cutting unit trims the product to size. This unit can be equipped with various cutting technologies, including shearing or flying cutter systems.

5. Control System Modern machines come equipped with advanced control systems that allow operators to monitor and adjust parameters such as speed, tension, and cutting length. Many machines also include touch-screen interfaces for easier operation.

Advantages of Square Downpipe Roll Forming Machines

One of the main benefits of using a square downpipe roll forming machine is the efficiency it brings to production. Traditional methods of fabricating downpipes can be time-consuming and labor-intensive. However, with a roll forming machine, manufacturers can produce large volumes of high-quality downpipes quickly and with minimal waste.

1. Precision and Consistency

The roll forming process inherently provides high precision, resulting in uniform products that meet strict quality standards. This is crucial for applications in construction where dimensional accuracy is essential for fitting parts together.

2. Material Efficiency

Roll forming optimizes the use of raw materials. The continuous process reduces scrap and waste, making it a more sustainable option for manufacturers aiming to minimize their environmental impact.

3. Versatility

Square downpipe roll forming machines can be customized to produce a variety of profiles and sizes. This versatility allows manufacturers to cater to different project requirements without needing multiple machines.

4. Cost-Effectiveness

Though the initial investment in a roll forming machine can be significant, the reduction in labor costs and material waste typically leads to lower production costs in the long run. Additionally, the speed of production can result in faster turnaround times and enhanced profitability.

Applications in the Industry

Square downpipes are essential components in various construction and roofing systems. They are primarily used to direct rainwater from roofs and gutters down to the ground or drainage systems. Their durability and resistance to corrosion make them ideal for both residential and commercial applications. The demand for square downpipes in building construction, infrastructure development, and urban drainage systems continues to grow, highlighting the importance of efficient manufacturing methods.

Conclusion

In summary, square downpipe roll forming machines represent a significant advancement in the metal fabrication industry. By providing high efficiency, precision, and versatility, these machines enable manufacturers to meet the growing demand for high-quality square downpipes. As construction projects become increasingly complex and require more specialized components, the role of roll forming technology is only expected to expand, making it a critical investment for forward-thinking manufacturers in today's competitive market.