The Square Downpipe Roll Forming Machine An Essential Tool for Modern Construction

In the construction and building materials industry, the efficiency and quality of components are crucial for any successful project. One innovative solution that has gained popularity is the square downpipe roll forming machine. This equipment seamlessly transforms metal sheets into square downpipes, essential for effective rainwater drainage systems. In this article, we will explore the significance, working principle, advantages, and applications of square downpipe roll forming machines.

Significance of Square Downpipes

Square downpipes play a vital role in directing rainwater from roofs to drainage systems. Their design ensures that water is channeled efficiently, reducing the risk of water damage and enhancing the durability of structures. The square shape allows for better aesthetics and integration with modern building designs. Therefore, the demand for high-quality square downpipes is ever-growing in the construction industry.

Working Principle of the Machine

The square downpipe roll forming machine operates through a systematic process that involves several key steps

1. Feeding The process begins with feeding a metal coil into the machine. This coil is typically made of materials such as galvanized steel, aluminum, or stainless steel, ensuring durability and resistance to corrosion.

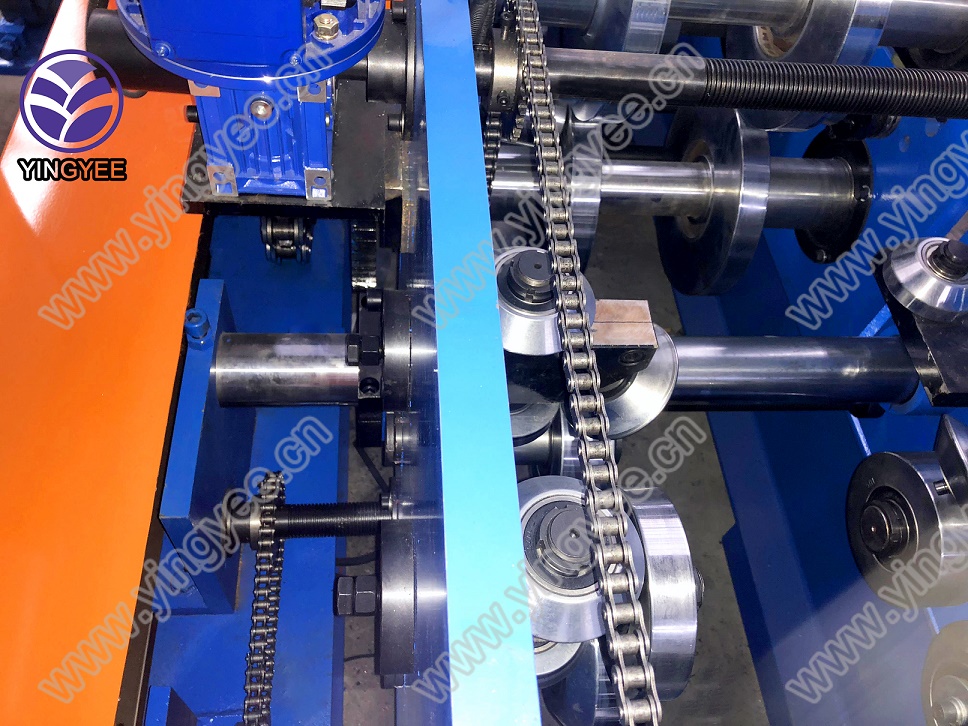

2. Forming As the coil moves through the machine, a series of rollers shape the flat metal strip into a square profile. The alignment of these rollers is crucial, ensuring that each segment of the downpipe maintains exact dimensions while avoiding any distortions.

3. Cutting Once the desired shape is formed, a cutting mechanism trims the downpipe to the specified length. This precision cutting guarantees uniformity across all produced downpipes.

4. Stacking The finished downpipes are then stacked neatly for easy handling and transportation.

This streamlined process significantly reduces production time and labor costs compared to traditional manufacturing methods.

Advantages of Square Downpipe Roll Forming Machines

1. Efficiency The automated process minimizes workforce requirements and maximizes output, allowing manufacturers to meet high demands efficiently.

2. Cost-Effectiveness Reduced material waste during the forming process leads to lower production costs. Additionally, the durability of the products ensures a longer lifespan, benefiting both manufacturers and end users.

3. Customization These machines can be easily adjusted to produce different sizes and shapes, allowing for custom orders to meet individual project needs.

4. Quality Control The precision of roll forming delivers high-quality end products, ensuring that all downpipes meet industry standards and specifications.

Applications

Square downpipe roll forming machines find extensive applications in various sectors, including residential, commercial, and industrial construction. They are particularly popular in regions with high rainfall, where effective drainage systems are critical. Furthermore, they can be used in the manufacturing of custom rainwater harvesting systems, showcasing their versatility.

Conclusion

The square downpipe roll forming machine represents a significant advancement in the production of essential construction components. With its efficiency, cost-effectiveness, and ability to produce high-quality products, it has become indispensable in modern architectural projects. As demand for sustainable construction practices continues to rise, investing in such innovative machinery is not only a smart business move but also a commitment to contributing to responsible building practices. Embracing technology like the square downpipe roll forming machine is vital for any manufacturer looking to thrive in today’s competitive market.