Square Pipe Roll Forming Machine Revolutionizing Metal Fabrication

In the realm of modern metal fabrication, square pipe roll forming machines have emerged as essential tools that significantly enhance efficiency and precision. These advanced machines are designed to convert metal strips into square or rectangular pipes through a series of precisely organized rolls. The process not only streamlines production but also ensures the uniformity and durability of the finished products, making it an invaluable asset in various industries.

Understanding the Roll Forming Process

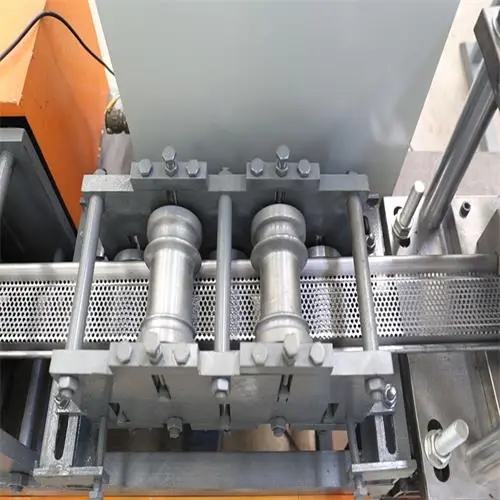

The roll forming process begins with feeding metal strips, typically made from steel or aluminum, through a series of rollers that progressively shape the metal into the desired cross-section. As the strip passes through each set of rollers, it gradually takes on the intricate shape required for square pipes. This method is highly efficient, particularly for high-volume production, as it allows for continuous processing without the need for additional cutting or jointing techniques.

Unlike traditional methods of pipe manufacturing, such as welding or extruding, the roll forming process minimizes waste and maximizes the structural integrity of the product. Since the metal is formed at room temperature, the risk of distortion or changes in material properties is significantly reduced, leading to high-quality outputs that meet stringent industry standards.

Key Features of Square Pipe Roll Forming Machines

1. Customization One of the standout features of square pipe roll forming machines is their customizable nature. Manufacturers can easily alter the design of the rollers to create pipes of various dimensions, thicknesses, and profiles, catering to specific customer requests or project requirements.

2. Automation Many modern machines are equipped with automation technology, enabling precise control over the entire forming process. Features such as programmable logic controllers (PLCs) help streamline operations, reduce manual labor, and enhance overall productivity.

3. Efficiency and Speed These machines are engineered for high-speed operations, allowing manufacturers to produce large quantities of square pipes in a relatively short period. This efficiency not only increases output but also reduces production costs, making it a financially viable solution for many businesses.

4. Quality Control Integrated quality control systems are often employed within these machines to monitor various parameters, such as material thickness and dimensions, throughout the forming process. This ensures that every piece meets the required specifications, reducing the need for rework and waste.

Applications of Square Pipes

Square pipes produced through roll forming are widely used in construction, automotive, furniture manufacturing, and many other sectors. They serve as structural components for buildings, frameworks for machinery, and even as aesthetic elements in contemporary furniture design. The versatility of square pipes makes them indispensable across multiple applications.

Conclusion

Square pipe roll forming machines are transforming the way metal fabrication is approached in industries worldwide. With their efficiency, precision, and ability to produce high-quality products, these machines not only meet the demands of modern manufacturing but also pave the way for innovation and growth in the field. As technology continues to advance, we can only expect further improvements in roll forming techniques, enhancing the capabilities of square pipe production and expanding their applications in the industrial landscape. Embracing these cutting-edge machines is crucial for manufacturers aiming to stay competitive and deliver superior products to their clients.