The Role of Solar Mounting Brackets Roll Formers in Modern Solar Energy Systems

In recent years, the surge in solar energy adoption has been propelled by a growing awareness of the need for sustainable energy sources. As solar panels become a common sight on rooftops and open fields, the components that support these solar arrays play a crucial role in ensuring their efficiency and durability. One such component is the solar mounting bracket, and its manufacturing process through roll forming is a fundamental aspect of the solar industry's infrastructure.

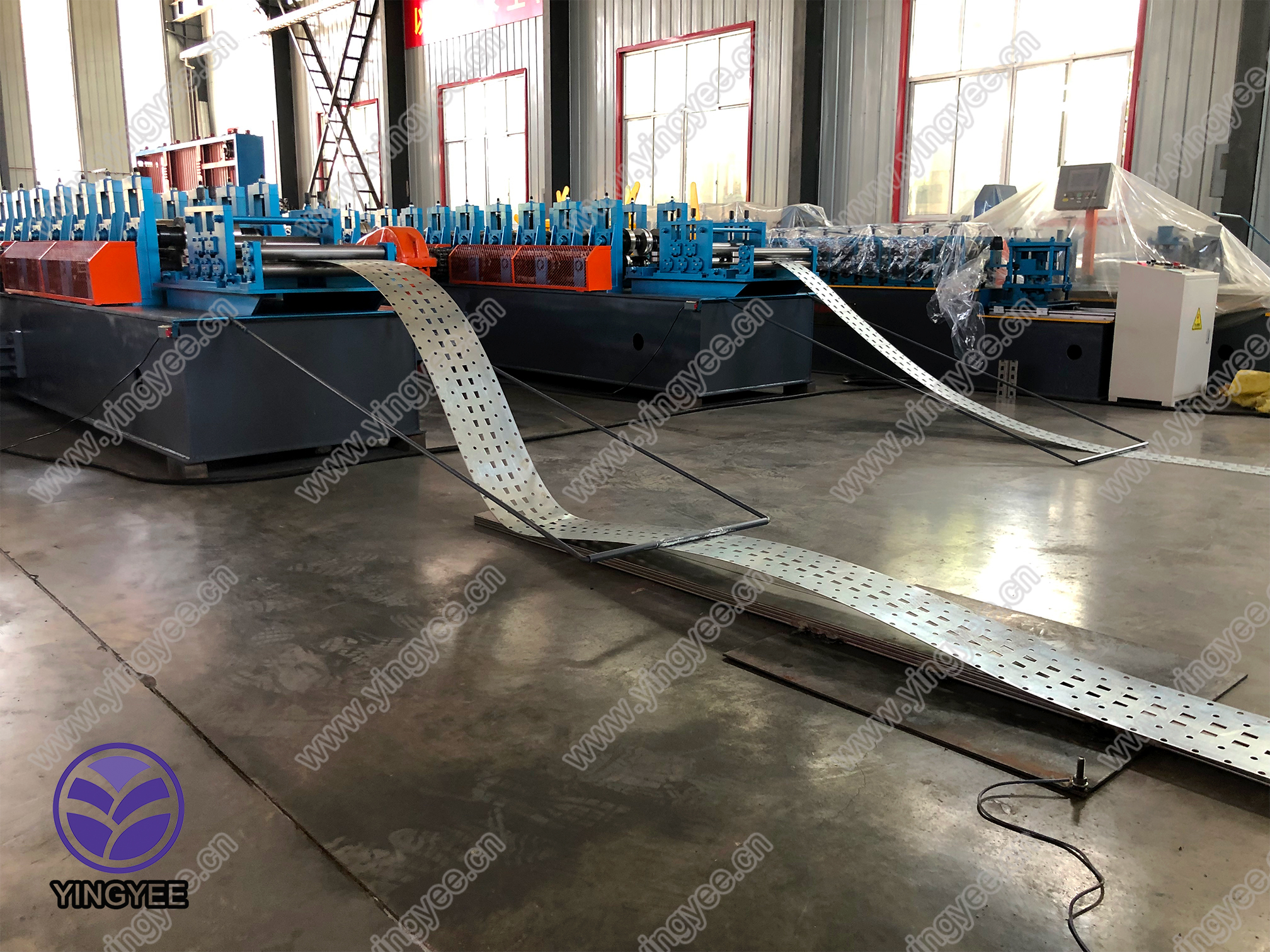

Solar mounting brackets are essential for securing solar panels in place, ensuring they remain stable and oriented correctly to capture maximum sunlight. As the demand for solar energy increases, the need for effective, efficient, and durable mounting solutions has also risen. This is where the roll former comes into play. Roll forming is a process that involves feeding a strip of metal through a series of rollers that progressively shape it into a desired profile. This method is particularly advantageous for producing mounting brackets due to its ability to turn out long lengths of uniform and precise components with minimal waste.

Efficiency and Precision in Manufacturing

One of the standout features of using roll formers in the production of solar mounting brackets is their ability to maintain high levels of precision while ensuring rapid production. These machines can create intricate designs that meet specific structural requirements, thus providing manufacturers the flexibility to cater to different solar panel configurations and installation environments. The precision of roll forming is vital, as any slight deviation in the mounting brackets can compromise the entire solar installation's performance and safety.

Moreover, roll forming is known for its efficiency in material usage. By utilizing a continuous strip of metal, manufacturers can significantly reduce scrap material compared to traditional cutting methods. This efficiency not only decreases the overall cost of production but also aligns with the sustainability goals of the solar energy sector. As green building practices become more prevalent, reducing waste in the production process is a crucial aspect of the industry's evolution.

Material Versatility and Durability

The adaptability of roll formers allows for the use of a variety of materials, such as aluminum and stainless steel, which are commonly used for solar mounting brackets. The choice of material is vital, as it must withstand harsh environmental conditions while remaining lightweight and easy to install. Aluminum, for instance, is corrosion-resistant and lightweight, making it an ideal option for various mounting applications. Stainless steel, while heavier, offers exceptional strength and durability, making it suitable for ground-mounted solar systems that endure more extreme weather conditions.

Furthermore, advanced roll forming technology allows for the integration of additional features into the mounting brackets during the manufacturing process. Holes for mounting bolts, channels for wiring, or even integrated designs that improve wind resistance can be included without the need for additional processes. This capability enhances the functionality of the brackets and simplifies the installation process, providing further benefits to both manufacturers and installers.

Future Innovations and Trends

As the solar energy sector continues to grow, the role of roll formers in producing solar mounting brackets is likely to expand and evolve. Innovations in manufacturing technology, such as automation and the use of artificial intelligence, promise to increase production speeds and further enhance precision. Moreover, the increasing importance of renewable energy and new regulatory standards may drive more manufacturers to adopt advanced roll forming techniques.

Additionally, customization will become a defining trend. As solar installations become more complex and tailored to individual needs, the ability to quickly modify designs and production runs will be critical. Roll formers are uniquely positioned to meet this demand, enabling manufacturers to adapt swiftly to changing client requirements, thus supporting the growth of the solar industry.

In conclusion, solar mounting brackets play a pivotal role in the installation and efficiency of solar energy systems, and the roll forming process is central to their production. With its blend of efficiency, precision, and adaptability, roll forming offers a sustainable and practical solution for meeting the growing demands of the solar market. As technology continues to advance, the future of solar mounting bracket production looks bright, heralding a new era of innovation in renewable energy manufacturing.