Understanding Solar Structure Roll Forming Machines

In recent years, the increasing demand for renewable energy sources has propelled the solar industry to new heights. Among the essential components of solar energy systems are the structural supports that hold solar panels in place. The efficiency and durability of these structures depend heavily on the manufacturing processes, and this is where solar structure roll forming machines come into play.

What is a Roll Forming Machine?

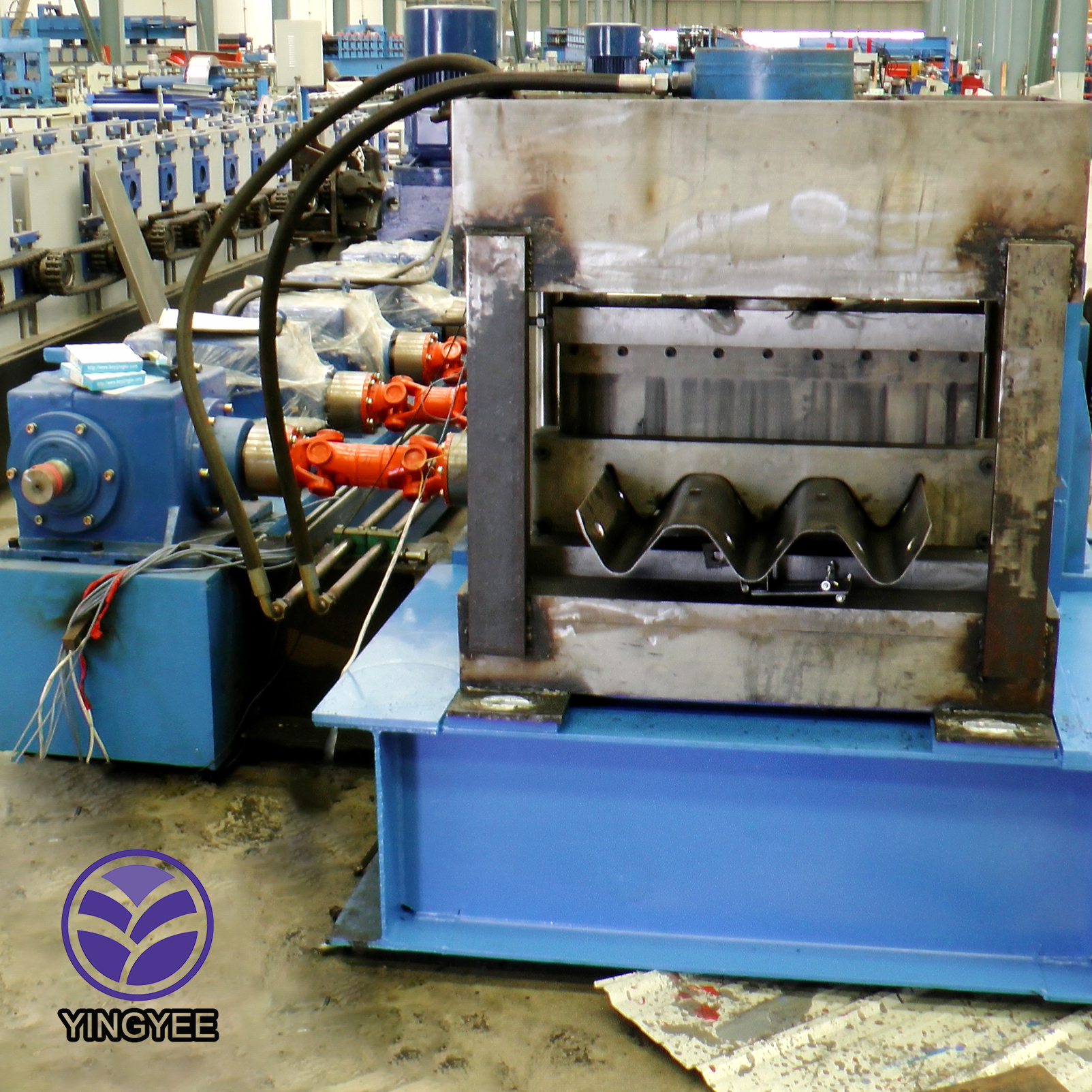

Roll forming is a continuous manufacturing process used to shape metal into specific cross-sectional profiles. A roll forming machine consists of a series of rollers that gradually bend flat metal strips into the desired shape as they pass through the machine. This method is highly efficient and suitable for producing long lengths of uniform profiles, making it particularly adaptable for solar structure components, such as mounting frames, brackets, and racking systems.

The Significance of Solar Structure Roll Forming Machines

1. Efficiency and Speed One of the primary advantages of roll forming machines is their speed. They can produce substantial lengths of profile quickly, which is essential given the rising demand for solar energy solutions. The continuous nature of the process allows for high output rates, reducing labor costs and production time.

2. Precision and Quality Solar structure roll forming machines are designed to deliver high precision. By using advanced technology and computer numerical control (CNC), manufacturers can create profiles that meet specific design and strength requirements. This ensures that each component fits perfectly during assembly, minimizing waste and enhancing the overall quality of the solar system installation.

3. Material Versatility Roll forming machines can process various materials, including steel, aluminum, and other alloys. This versatility allows manufacturers to select materials best suited for particular environmental conditions or application requirements. For instance, aluminum profiles may be preferred for their lightweight and corrosion-resistant properties, ideal for rooftop solar installations.

4. Customizability Another key benefit of solar structure roll forming machines is the ability to customize profiles. Different solar projects may require specific structural designs; roll forming allows for the quick adaptation of machine settings to produce unique profiles tailored to individual project specifications.

5. Cost-Effectiveness Although the initial investment for a roll forming machine may be significant, the long-term savings can be substantial. The efficiency, reduced waste, and lower labor costs associated with roll forming can lead to a favorable return on investment. Additionally, the durability of the produced components translates into lower maintenance costs over time.

Trends and Innovations

As the solar industry continues to evolve, so too does the technology behind solar structure roll forming machines. Innovations such as automated handling systems, integrated quality control measures, and enhanced software for design flexibility are becoming increasingly common. These advancements not only improve the efficiency and precision of manufacturing processes but also contribute to the overall sustainability of solar energy production.

Furthermore, as research progresses in materials science, manufacturers are exploring lighter and more robust materials, providing new opportunities for design improvements in solar structures.

Conclusion

In conclusion, solar structure roll forming machines are critical to the efficient and high-quality production of components necessary for solar energy systems. With their ability to provide fast, precise, and customizable manufacturing solutions, these machines play a vital role in propelling the growth of renewable energy. As technology continues to advance, the potential for enhancing the efficiency and sustainability of solar structures will only increase, making these machines indispensable in the fight against climate change. The future of solar energy looks brighter than ever, with roll forming technology at its core.