The Importance of Slitting Line Machines in Modern Manufacturing

In today’s fast-paced manufacturing landscape, efficiency and precision are paramount. Among the various types of machinery that contribute to these goals, slitting line machines play a critical role. These machines are specifically designed for processing wide coils of metal or other materials, cutting them into narrower strips with high accuracy and minimal waste.

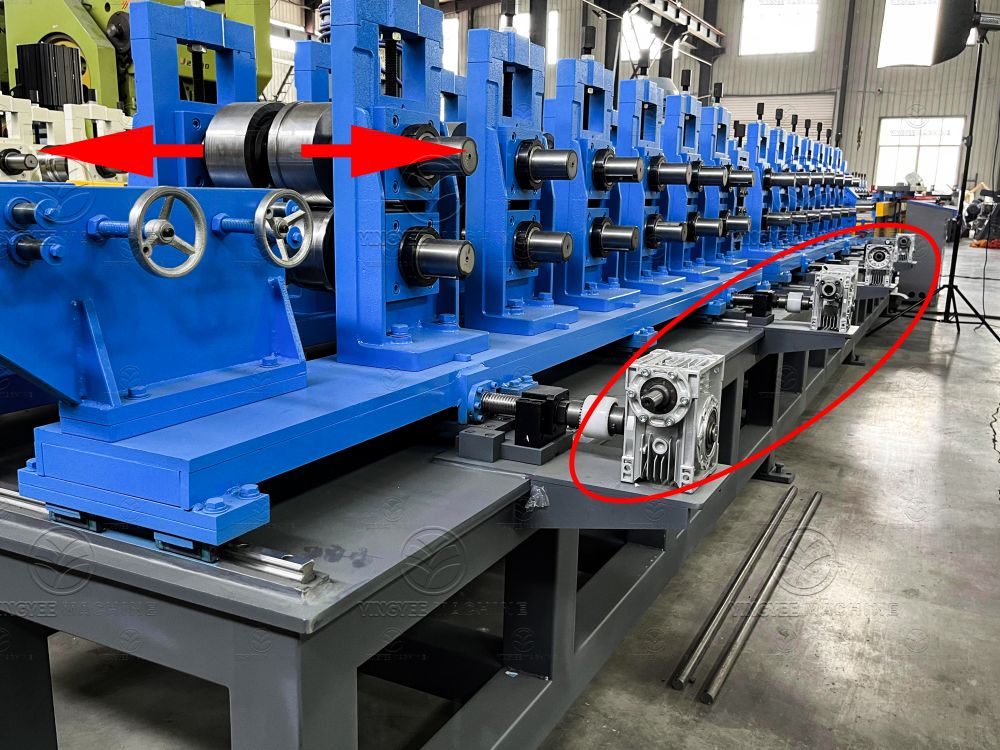

A slitting line typically consists of several key components unwinding reels, slitting knives, a tension control system, and recoiling units. The process begins with the unwinding of a large coil of material, which is fed into the machine. As the material passes through, the slitting knives perform the vital function of cutting the material into specified widths. This operation requires not only sharp blades but also precise control over the speed and tension of the material to ensure uniform cuts.

One of the primary benefits of utilizing slitting line machines is the significant reduction in material waste. Modern slitting lines are engineered to optimize the cutting process, allowing manufacturers to maximize yield from the raw materials. This efficiency not only saves costs but also supports sustainable manufacturing practices by minimizing waste.

Flexibility is another significant advantage offered by slitting line machines. Many contemporary models come equipped with advanced features that allow operators to modify the machine settings quickly to accommodate different materials and thicknesses. This adaptability is essential in industries such as automotive, construction, and appliance manufacturing, where varying specifications are the norm.

Moreover, advancements in technology have enhanced the capabilities of slitting line machines. Automation and computer-controlled systems improve the consistency and quality of the cuts, reducing the likelihood of human error. Incorporating sensors and feedback mechanisms allows for real-time monitoring of the slitting process, enabling immediate adjustments to be made if any deviations from the desired parameters occur.

In addition to improving the efficiency of the cutting process, slitting line machines often contribute to the overall safety of manufacturing operations. By automating the more hazardous aspects of metalworking, these machines reduce the risk of injury to workers. Furthermore, the precise nature of these machines ensures that materials are cut accurately, minimizing the need for rework and additional handling that can pose safety risks.

In conclusion, slitting line machines are an indispensable component of modern manufacturing. Their ability to efficiently process materials with precision not only enhances productivity but also supports sustainability and safety in the workplace. As industries continue to evolve, the importance of investing in advanced slitting line technology cannot be overstated. Manufacturers that leverage these machines are likely to achieve competitive advantages in both cost-effectiveness and product quality, securing their position in an increasingly competitive market.