The Significance of Slitting Lines in Modern Manufacturing

In the fast-paced world of manufacturing, efficiency and precision are critical. One of the key technologies that have emerged to support these demands is the slitting line. Slitting lines are specialized machines designed to cut wide coils of material, such as steel or aluminum, into narrower strips with exceptional accuracy. This process is essential in various industries, including automotive, construction, and appliance manufacturing. Understanding the functionality and benefits of slitting lines can shed light on their significance in modern manufacturing.

What is a Slitting Line?

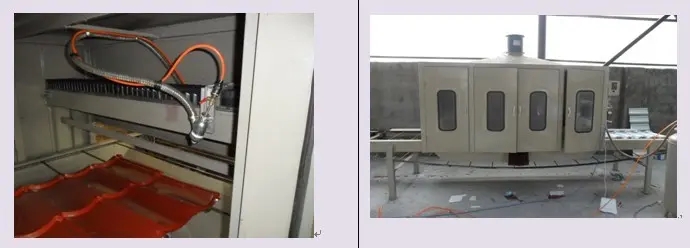

A slitting line primarily consists of several important components a pay-off reel that feeds the coil, a slitting head where the actual cutting occurs, a scrap removal system, and a recoiler that collects the finished strips. The process begins with an oversized coil, which is unwound and fed into the slitting machine. As the coil passes through the slitting head, rotary knives slice the material into narrower strips based on specified widths. Once cut, these strips are recoiled onto a new reel, ready for further processing or distribution.

Applications Across Industries

The versatility of slitting lines allows them to serve a wide array of industrial applications. In the automotive industry, for example, slitting lines are critical for producing parts that require specific dimensions and tolerances. These components may include car frames, body panels, or other structural elements. The flexibility of slitting lines enables manufacturers to tailor the widths and thicknesses of coils to meet precise specifications, ensuring that they can produce high-quality parts efficiently.

Similarly, the construction industry relies heavily on slitting lines for producing materials such as steel studs, tracks, and other framing members. The need for lightweight yet robust materials is paramount in modern construction, and slitting lines facilitate the production of customized sizes to cater to various building requirements.

Moreover, appliance manufacturers utilize slitting lines to supply materials for everything from refrigerators to washing machines

. The ability to generate narrow strips from large coils allows for effective resource utilization, minimizing waste and optimizing production processes.

Advantages of Slitting Lines

The implementation of slitting lines brings numerous advantages to manufacturing operations. First and foremost, precision is a hallmark of slitting machines. These systems operate with tight tolerances, ensuring that each strip meets the required specifications. This precision reduces the likelihood of defects, which can lead to costly rework or scrap.

Additionally, slitting lines enhance production efficiency. Instead of cutting sheets of material individually, which can be time-consuming, a slitting line processes large coils in a continuous manner. This not only speeds up production but also reduces manual labor, as the automation of the process minimizes human intervention.

Cost savings are another significant benefit. By optimizing the material utilization and generating precisely sized strips, manufacturers can reduce waste and lower material costs. Furthermore, the ability to produce a diverse range of strip widths allows companies to respond quickly to market demands, fostering customer satisfaction through timely delivery of varied product sizes.

The Future of Slitting Lines

As industries evolve, so too do slitting lines. Advances in technology, including automation and Industry 4.0 integration, are paving the way for smarter slitting machines. Future developments may include enhanced monitoring systems that analyze production processes in real-time, allowing for instant adjustments to maintain optimal efficiency and quality.

Moreover, the increasing demand for sustainable manufacturing practices has prompted slitting line manufacturers to explore eco-friendly innovations. This includes designs that minimize energy consumption and waste generation, aligning with global sustainability goals.

In conclusion, slitting lines play a pivotal role in modern manufacturing, providing essential capabilities that contribute to efficiency, precision, and adaptability across various industries. As technological advancements continue to shape the landscape of manufacturing, slitting lines will undoubtedly evolve, further solidifying their importance in the quest for optimized production processes. By embracing innovation, the future of slitting lines looks promising, poised to meet the challenges of a dynamic market and the ever-increasing demands for high-quality, customized products.