The Slitting Line An Essential Process in Metal Fabrication

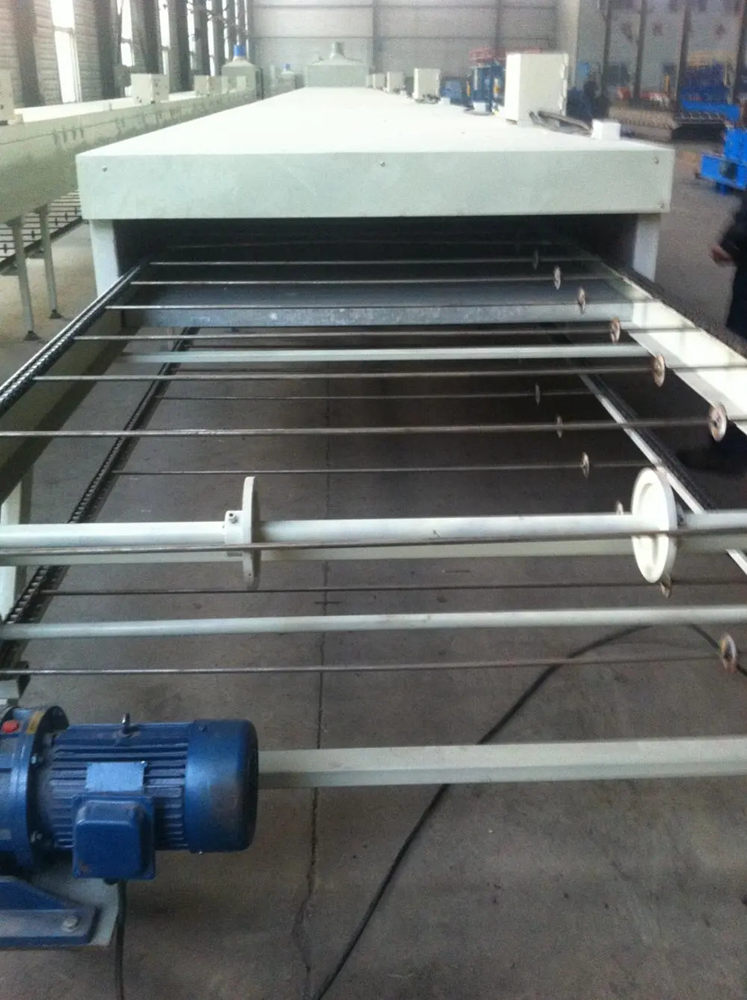

In the realm of metal fabrication, the slitting line plays a crucial role in the production of various metal products. This sophisticated machinery is designed to convert large coils of metal into narrower strips with precise dimensions, making it an integral part of industries such as automotive, construction, and electronics.

The slitting process starts with the unwinding of a large metal coil—often made of steel, aluminum, or other alloys—on an unwinding stand. This coil typically weighs several tons and can measure anywhere from 30 to 60 inches in width. Once the coil is securely positioned on the uncoiler, it is fed through a series of tension controls and guides to ensure smooth feeding into the cutting section of the slitting line.

At the heart of the slitting line are the slitting blades, which are designed to cut the metal coil into multiple strips. These blades can vary in size and shape, depending on the thickness and type of metal being processed. The precision of the slitting blades is vital, as it directly affects the quality of the finished strips. The blades typically operate at high speeds, cutting through the metal with greater efficiency than traditional shearing methods.

After the cutting process, the newly formed strips are collected and rewound onto payoff reels. These reels can be customized according to customer specifications, allowing for a wide variety of strip widths and lengths. The finished products are then ready for further processing, such as punching, forming, or even direct shipment to customers.

One of the key advantages of using a slitting line is its ability to maintain high levels of precision and quality. Modern slitting lines are equipped with advanced technology that allows for consistent strip widths and minimal tolerance variations. This precision is essential for applications where exact measurements are critical, such as automotive component manufacturing.

Additionally, the slitting line process contributes to waste reduction. By optimizing the cutting patterns and using advanced software to plan the slitting process, manufacturers can ensure that they minimize scrap material. This not only enhances the overall efficiency of production but also aligns with sustainability goals, a growing concern in today’s industrial landscape.

In conclusion, the slitting line is a fundamental tool in metal fabrication that ensures high efficiency, precision, and productivity. As industries continue to evolve and demand more customized products, the importance of slitting lines will only increase. By integrating advanced technologies and innovative practices, manufacturers can continue to meet the challenges of the modern market while maintaining quality and efficiency.