Understanding the Pricing of Slitting Line Machines

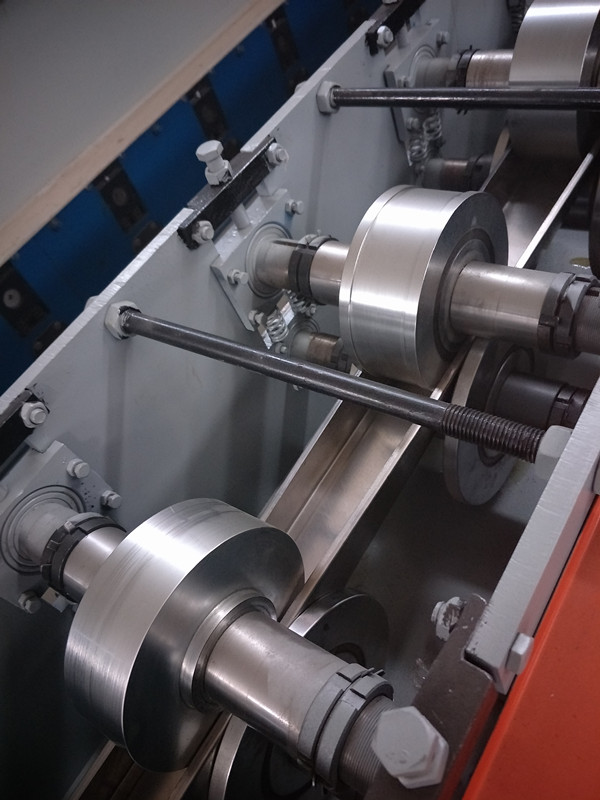

Slitting line machines play a crucial role in the metal processing industry, specifically for the cutting of coils into narrower strips. They are essential for manufacturers who require precise cutting and handling of steel, aluminum, and other materials. This article aims to provide an overview of the factors affecting the prices of slitting line machines and what potential buyers can expect from different price ranges.

Factors Influencing Slitting Line Machine Prices

1. Machine Specifications The configuration and capabilities of a slitting line machine are primary determinants of its price. Machines designed for higher throughput, greater precision, or additional features such as automatic tension control or thickness adjustment will naturally cost more. Standard machines with fewer features may be more affordable, but may not meet the exact needs of high-demand operations.

2. Production Capacity Slitting line machines vary in their production capacities, typically measured in millimeters or inches of material that can be processed per minute. Higher production speeds generally lead to higher prices. Businesses must consider their production needs; investing in a high-capacity machine may yield better returns for companies with extensive slitting requirements.

3. Material Type The type of material being processed can also affect the price of the slitting line machine. Machines designed to cut harder materials like stainless steel or specialty alloys may require enhanced cutting capabilities and durability, leading to increased costs. Conversely, machines suitable for softer materials like aluminum may be less expensive.

4. Automation and Technology The integration of advanced technology and automation into slitting lines can drive up initial costs but may reduce labor costs and improve efficiency over time. Features such as automated feeding systems, real-time monitoring, and advanced safety systems can influence pricing significantly but should also be weighed against potential long-term savings.

5. Brand Reputation and Quality The reputation of the manufacturer plays a significant role in pricing. Well-established brands with proven reliability and quality assurance often charge a premium for their machines. This investment can be worthwhile for companies looking for dependable equipment that will last over time.

Price Ranges and Expectations

Generally, the price of slitting line machines can range from $50,000 to over $500,000, depending on the factors mentioned above. Entry-level models designed for smaller operations may be at the lower end of this spectrum, whereas high-performance machines with tailored specifications and advanced features will be positioned at the higher end.

When evaluating the price of slitting line machines, potential buyers should conduct thorough research, comparing different manufacturers, and understanding their unique features and capabilities. It is essential to assess both the initial investment and the machine's operational costs, including maintenance, labor, and energy consumption, to determine the overall value.

Conclusion

Investing in a slitting line machine can be a significant financial decision for many businesses. By understanding the various factors that influence pricing, companies can make well-informed choices tailored to their production needs. Ultimately, the right machine can significantly enhance productivity and efficiency, yielding substantial returns on investment in the competitive metal processing industry.