Single Z Purlin Forming Machine Revolutionizing Construction and Design

In the realm of modern construction, the importance of structural integrity and efficiency cannot be overstated. One of the pivotal components in achieving these objectives is the use of purlins. Purlins are horizontal members used to support roofing and wall systems and play a crucial role in distributing loads within a structure. Among various types of purlins, the Single Z purlin stands out for its unique design and functionality. The development of Single Z Purlin Forming Machines has revolutionized the manufacturing process, making it more efficient and economically viable for builders and contractors.

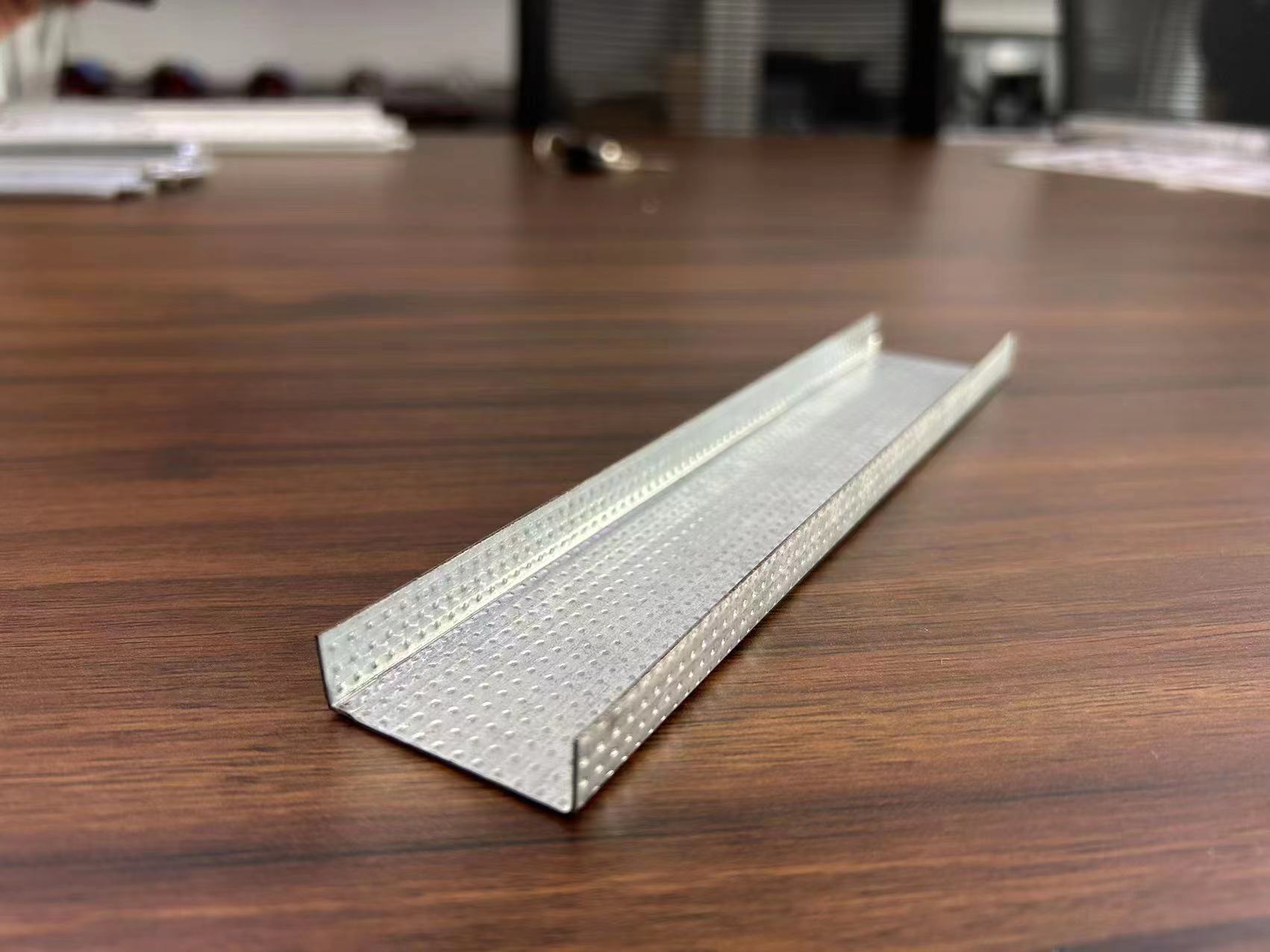

What is a Single Z Purlin?

Single Z purlins are distinguished by their Z shape when viewed in cross-section. They are typically used in steel buildings and structures to provide support for roof sheeting and wall cladding. The design of the Single Z purlin allows for effective load distribution, practical installation, and enhanced structural stability. Made primarily from high-strength steel, Z purlins are lightweight yet incredibly strong, allowing for longer spans and reducing the overall amount of material needed. This not only optimizes construction costs but also minimizes the environmental footprint of building projects.

The Role of Single Z Purlin Forming Machines

Single Z Purlin Forming Machines are specialized equipment designed to produce these essential structural components efficiently. The machines utilize advanced technology to transform flat steel sheets into accurately shaped Z purlins through a series of processes including shearing, bending, and cutting. This automation improves productivity and significantly reduces the labor required for manual fabrication.

Advantages of Single Z Purlin Forming Machines

1. Precision Manufacturing One of the standout features of Single Z Purlin Forming Machines is their ability to produce high-precision components. These machines are equipped with computerized control systems that ensure consistent quality in every batch of purlins produced.

2. Customization The machines can be easily adjusted to create purlins of various sizes and thicknesses, accommodating the specific requirements of different construction projects. This flexibility allows manufacturers to meet diverse market demands without the need for extensive retooling.

3. Cost-Effectiveness With the automation of the forming process, manufacturers can significantly reduce production costs and time. The efficiency gained through these machines translates to overall lower prices for contractors, enabling them to take on more projects and compete better in the market.

4. Durability and Strength The materials processed through Single Z Purlin Forming Machines are chosen for their durability. The resulting purlins not only meet but often exceed industry standards for strength, ensuring safety and reliability in structures.

5. Reduced Waste Advanced forming technologies help minimize scrap and waste during the manufacturing process, further enhancing the sustainability of using Single Z purlins in construction.

Conclusion

The advent of Single Z Purlin Forming Machines has marked a significant advancement in construction technology, enabling the efficient production of high-quality structural components. As demand for sustainable and cost-effective building solutions continues to rise, single Z purlins, facilitated by innovative forming machines, will play an increasingly vital role in the construction industry. This evolution not only highlights the technological advancements in manufacturing but also supports the broader goals of sustainability and efficiency in modern architecture and construction practices.