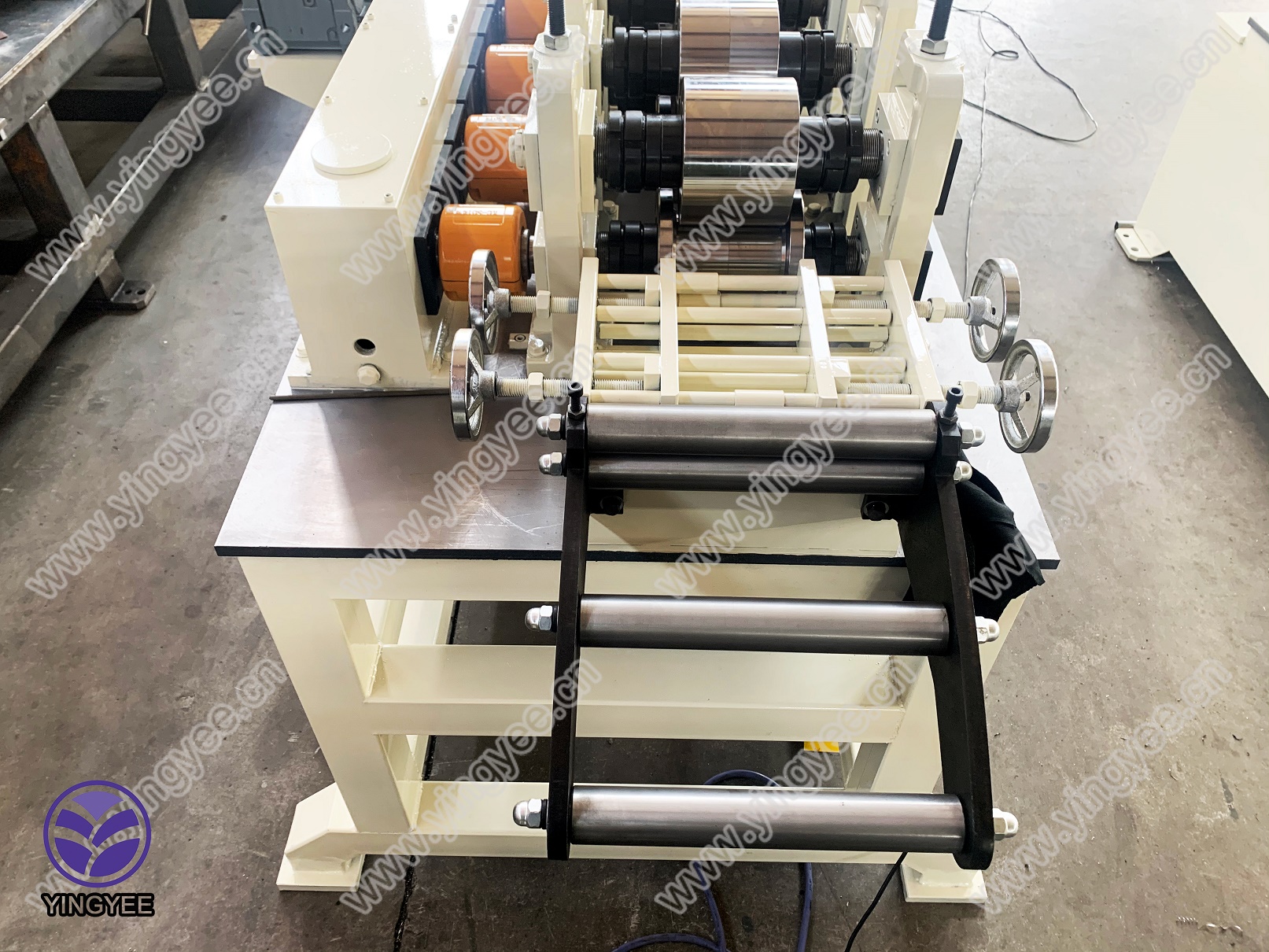

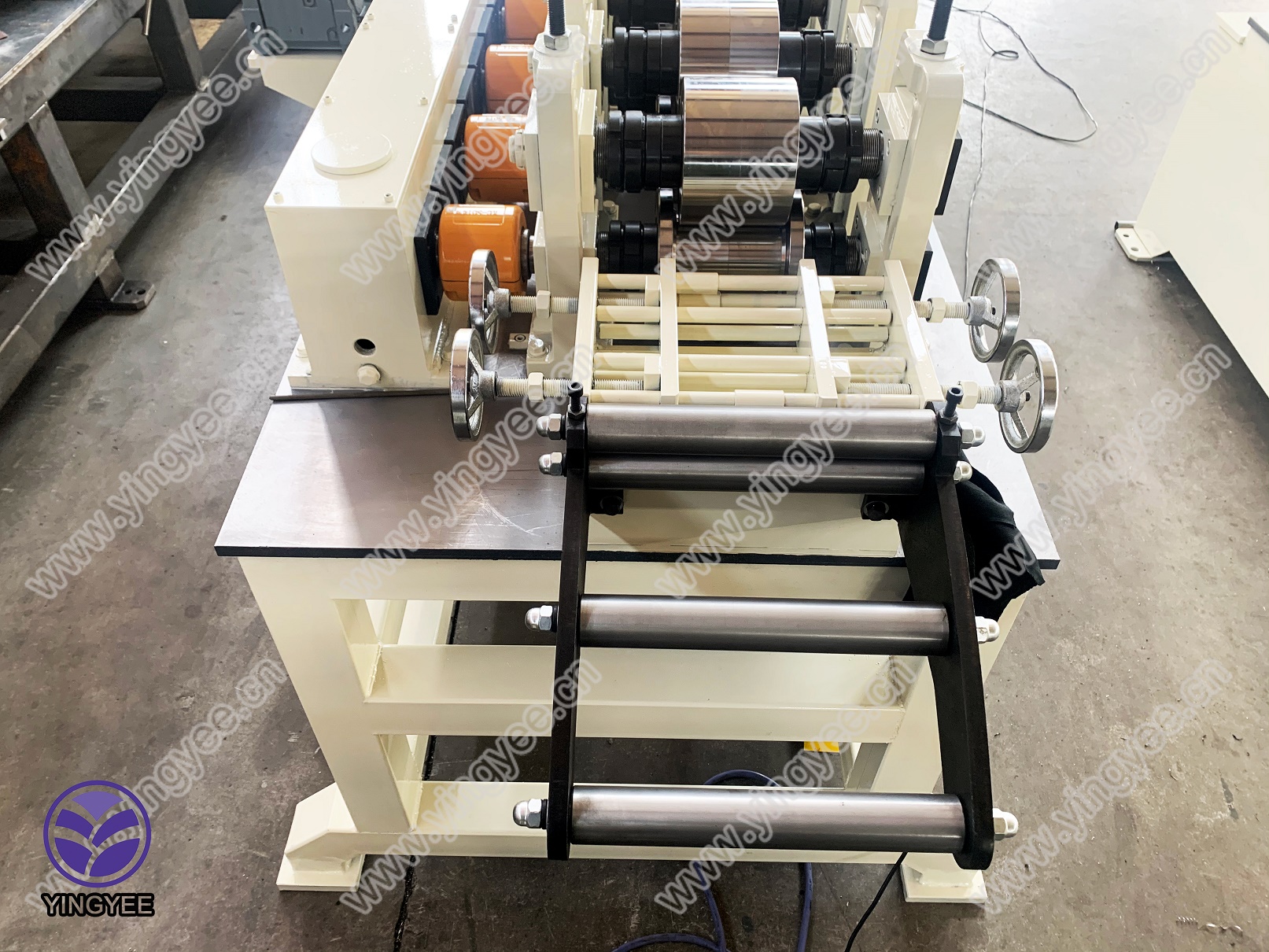

When it comes to the realm of industrial manufacturing, efficiency and precision are paramount. A simple slitting line often stands at the core of processing tasks, transforming rolls of material into manageable pieces with precision and speed. The relevance of this machinery cannot be overstated, particularly for industries that require high-volume, custom-sized flat sheets from coils, such as metal fabrication, paper production, and plastic processing.

Expertise in the field of slitting lines emphasizes their sheer importance. These machines are not simplistic by any means; rather, the term “simple” refers to their ingenious design that allows for efficient, repeated operations. At its core, a slitting line is designed to uncoil, slit, and recoil materials. The simplicity of its function belies its capability to handle complex tasks such as adjusting for different material thicknesses or varying slit widths. This adaptability makes the equipment indispensable for tailored manufacturing processes.

Experience in the operation of simple slitting lines reveals the nuanced handling required to optimize their performance. It involves mastering the art of material tension, precision alignment, and understanding the characteristics of different materials. An experienced operator knows that the quality of the end product depends significantly on the initial setup of the slitting line. The correct setup minimizes burrs, reduces edge waves, and prevents potential damage to the slit material edges, thus ensuring a superior quality finish.

The authority of simple slitting lines is demonstrated by their ubiquitous presence in manufacturing plants globally. Their design is continuously refined by leading industry manufacturers to cater to the exigencies of modern production standards. Improvements in automation, digital controls, and material handling have cemented their role as a trusted workhorse of the industry. Educational institutes and industry workshops often incorporate slitting line operation and maintenance into their curriculum, underscoring their fundamental status in industrial processes.

simple slitting line

Trustworthiness in the context of simple slitting lines is attained through a combination of robust engineering and reliable performance. Manufacturers often subject these machines to rigorous quality control and stress testing, ensuring that they can withstand high-speed operations over extended periods without failure. Moreover, the availability of comprehensive maintenance manuals and prompt customer support enhances their dependability, allowing operators to maintain peak operational efficiency.

From a product perspective, the selection of a simple slitting line should be driven by specific production needs – the type of material, required speed, width, and thickness capabilities. The right choice promises not only operational efficiency but also a significant return on investment due to reduced material wastage, minimized labor costs, and increased production throughput.

In conclusion, the elegance of a simple slitting line lies in its ingenious design and operational capability. Its role in the manufacturing process is undeniably critical, promoting efficiency and precision across various industries. Investing in a simple slitting line is invariably investing in a higher standard of production efficiency, and when equipped with the right knowledge and maintenance practices, it provides unparalleled value and reliability.