The Evolution and Importance of Simple Slitting Lines in Modern Manufacturing

In the realm of modern manufacturing, efficiency and precision are paramount. One of the unsung heroes in this arena is the simple slitting line, a vital component in the processing of various materials, particularly in the steel and aluminum industries. A simple slitting line is a machine designed to cut wide rolls of material into narrower strips, creating finished products that can be readily used in different applications. This article explores the significance, operation, and advancements in simple slitting lines.

Understanding Simple Slitting Lines

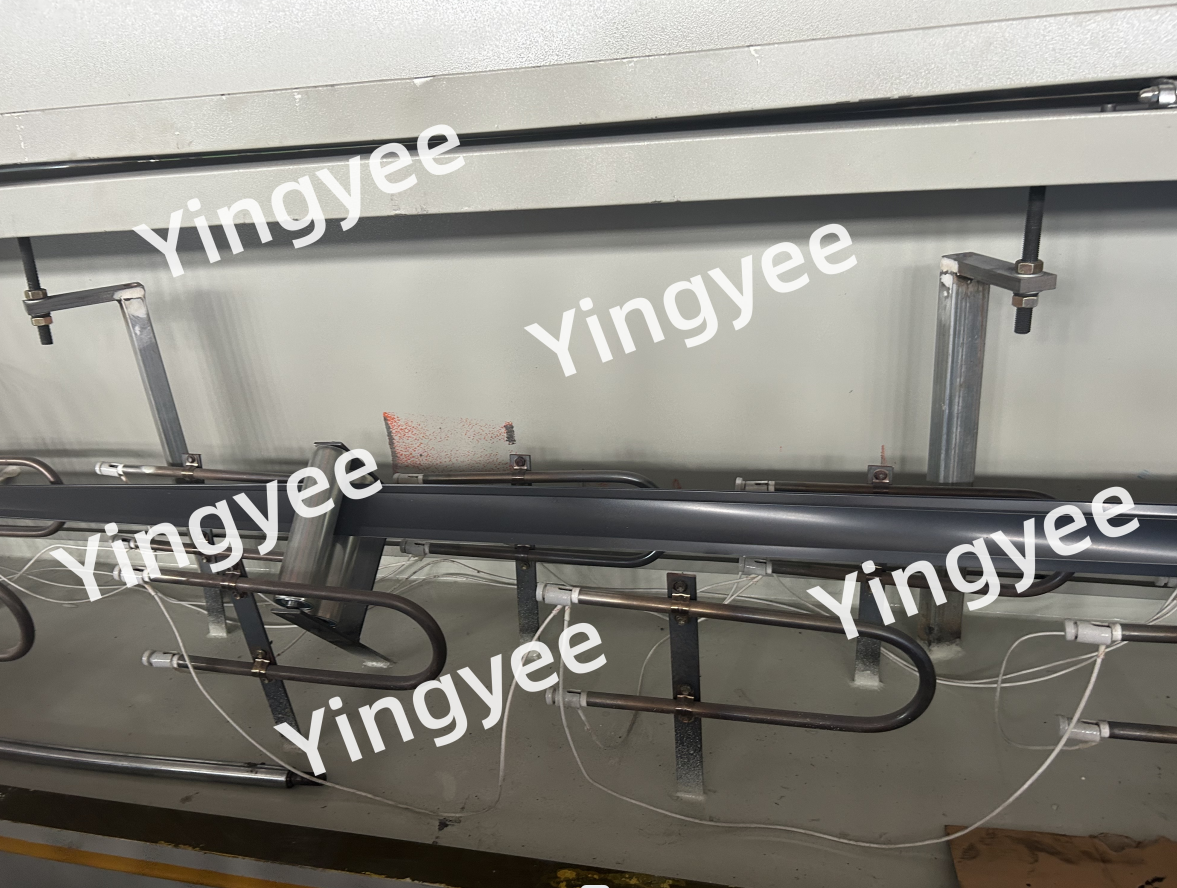

At its core, a simple slitting line consists of several key components, including a pay-off reel, slitting blades, and shear or rewind systems. The process typically begins with a large coil of material, known as a master roll, which is placed on the pay-off reel. This roll unwinds as the material is fed through the machine. The slitting blades, which can vary in number and width depending on the desired final product, slice the material into narrower strips. After slitting, the material is either recoiled into smaller rolls or cut to length, depending on customer specifications.

The Benefits of Simple Slitting Lines

One of the primary advantages of simple slitting lines is their ability to enhance productivity. By efficiently processing large rolls of material into smaller, more manageable widths, manufacturers can reduce waste and optimize usage. This is particularly important in industries where material costs are high, as it allows companies to maximize the utility of each roll of material.

Moreover, simple slitting lines offer versatility

. They can handle a variety of materials, from thin foils to thick sheets, making them suitable for a wide range of applications, including automotive, construction, and packaging. This adaptability means that manufacturers can respond promptly to market demands without the need for extensive equipment changes.

Advances in Technology

Over the years, simple slitting lines have undergone significant technological advancements. Modern machines are equipped with computer numerical control (CNC) systems, allowing for precise measurements and cuts. This level of accuracy not only improves the quality of the finished products but also reduces the potential for errors and waste. Additionally, features such as automatic tension control and real-time feedback systems have further enhanced operational efficiency.

An emerging trend is the integration of smart technology in simple slitting lines. Manufacturers are beginning to adopt Industry 4.0 principles, which incorporate connected machines and data analytics into production processes. This shift allows for real-time monitoring of equipment performance, predictive maintenance, and optimization of production schedules, leading to increased efficiency and reduced downtime.

Environmental Considerations

As the manufacturing industry becomes increasingly focused on sustainability, simple slitting lines are also adapting to eco-friendly practices. Newer models are designed to minimize energy consumption and waste generation. For instance, some machines are designed to reclaim and recycle scrap materials, thereby contributing to a circular economy. Moreover, the shift towards using lighter and more sustainable materials in manufacturing processes complements the capabilities of slitting lines.

Conclusion

Simple slitting lines play a crucial role in the manufacturing landscape, providing efficiency, versatility, and precision in the processing of materials. As technology continues to advance, these machines are becoming more sophisticated, integrating smart features that enhance productivity and sustainability. As industries strive to meet modern production demands and environmental standards, simple slitting lines will undoubtedly remain a critical component of manufacturing operations. The ongoing evolution of these machines underscores their importance in shaping the future of production, adapting to new challenges, and meeting the diverse needs of the market.