The Simple Slitting Line An Overview of Process and Benefits

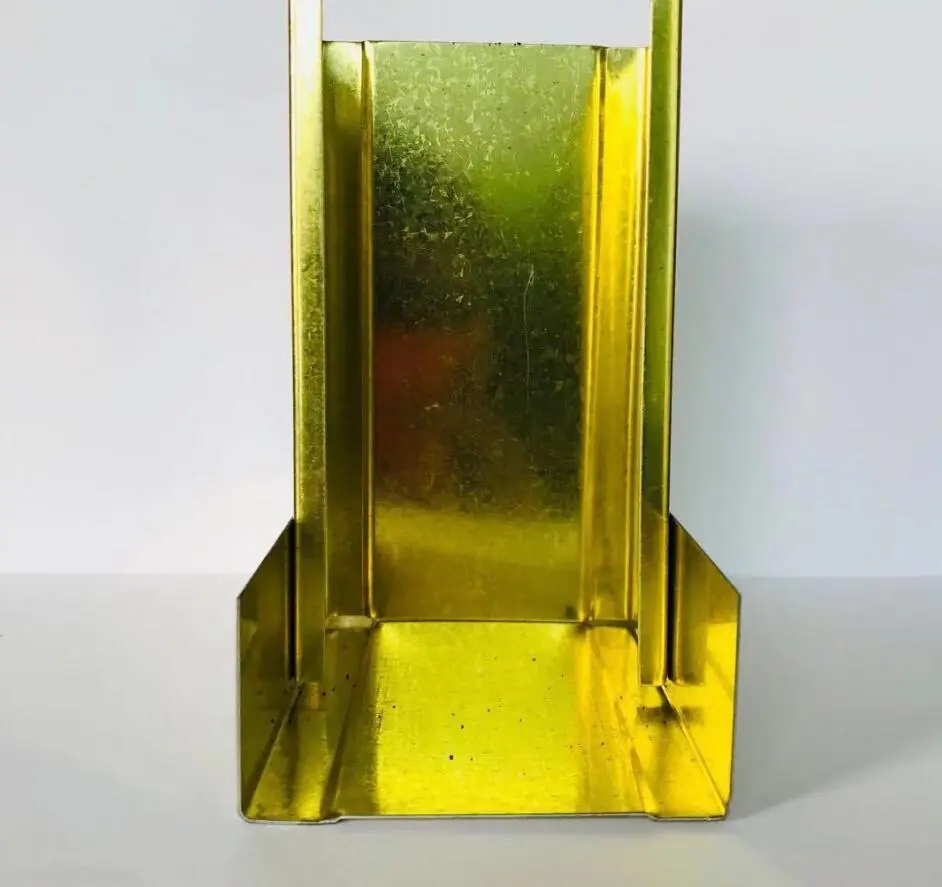

In the modern manufacturing landscape, efficiency and precision are paramount. One of the key processes that has gained significant attention is slitting, particularly through the use of a simple slitting line. Designed for high efficiency, a simple slitting line is an automated system that cuts wide rolls of materials into narrower strips, suitable for various applications in industries such as automotive, electronics, and packaging. This article provides an overview of what a simple slitting line is, how it works, and its benefits.

What is a Simple Slitting Line?

A simple slitting line is a type of equipment used to convert large rolls of material, usually metal or plastic, into narrower rolls or strips. The primary operation involves unwinding a master roll, cutting it into the desired widths, and then rewinding the finished strips into new rolls. This process can involve various materials, including steel, aluminum, copper, and other flexible materials, making slitting lines versatile tools in manufacturing.

How Does a Simple Slitting Line Work?

The operation of a simple slitting line can be broken down into several key steps

1. Unwinding The first step involves the unwinding of a large coil of material. The unwind stand, equipped with tension control, allows for smooth and controlled release of the material, which minimizes any damage or deformation.

2. Slitting As the material is unwound, it passes through a series of sharp blades or knives. These blades can be adjusted to cut the material into various widths, depending on the specifications required by the end user. The quality of the cut is crucial, as it affects the usability of the final product.

3. Rewinding After the material has been cut into narrow strips, the next stage involves rewinding the individual strips onto cores. This process can be performed by a set of rewind stands, which maintain constant tension to ensure that the strips are tightly wound and free from defects.

4. Finished Product Once the winding is complete, the finished rolls are ready for packaging or direct shipment to customers. Quality checks are conducted at various stages to ensure that the final products meet industry standards.

Benefits of a Simple Slitting Line

The implementation of a simple slitting line offers numerous advantages to manufacturers

1. Increased Efficiency Automated slitting lines can operate at high speeds, significantly reducing the time it takes to produce finished products. This efficiency translates into higher output and lower labor costs.

2. Precision Cutting The use of precise blades and automated controls allows for consistent and accurate cutting. This precision minimizes waste and ensures that customers receive high-quality materials that meet their specifications.

3. Versatility Simple slitting lines can be designed to handle a variety of materials and can be easily adjusted to accommodate different cutting widths. This versatility makes them suitable for various industries, from automotive to consumer goods.

4. Reduced Material Waste By optimizing the cutting process and utilizing advanced technology, manufacturers can significantly reduce material waste. This not only lowers production costs but also aligns with sustainable manufacturing practices.

5. Ease of Operation Modern slitting lines are designed to be user-friendly, allowing operators to quickly set up and adjust the machines as needed. This ease of operation helps reduce training time and enhances overall productivity.

Conclusion

In conclusion, a simple slitting line is an essential tool in the manufacturing sector, offering a streamlined process for converting wide rolls of material into precise strips. The benefits of increased efficiency, precision cutting, and reduced waste position simple slitting lines as a valuable asset for businesses looking to enhance their production capabilities. As industries continue to evolve, the demand for reliable and efficient processing technologies will undoubtedly grow, making simple slitting lines a crucial component of modern manufacturing strategies. The ongoing developments in slitting technology promise to further enhance the capabilities of these systems, paving the way for more innovative and efficient manufacturing processes in the future.