Simple Debugging for Right Channel Roll Forming Machine

Roll forming is a popular manufacturing process that involves bending metal sheets into specific shapes through a series of rollers. One of the common applications of roll forming machines is to create right channel profiles, which are widely used in construction, automotive, and other industries. However, like any machinery, roll forming machines can face challenges, particularly during the debugging phase. Proper debugging not only ensures the efficiency of the machine but also improves product quality and reduces waste. This article aims to provide a simple guide for debugging a right channel roll forming machine.

Debugging a roll forming machine can be broken down into several critical steps inspecting components, checking alignment, adjusting settings, and testing the output.

1. Inspecting Components

The first step in debugging a roll forming machine is to thoroughly inspect all the components. This includes checking the rollers, drive system, and controls. Ensure that the rollers are free from dust, debris, or any foreign material that may affect their performance. Additionally, inspect the condition of the rollers for wear and tear. If any roller is damaged or excessively worn, it should be replaced immediately. Checking the drive system is also crucial; make sure that belts and gears are properly aligned and not exhibiting any signs of wear.

Next, ensure that the machine is correctly aligned. Misalignment can result in uneven or defective products. Use a leveling tool to check the horizontal and vertical alignment of the machine components. The rollers should be aligned parallel to each other; any discrepancies could lead to uneven shaping of the right channel. If misalignment is found, adjust the positioning of the rollers and locking devices until the machine is properly aligned.

3. Adjusting Settings

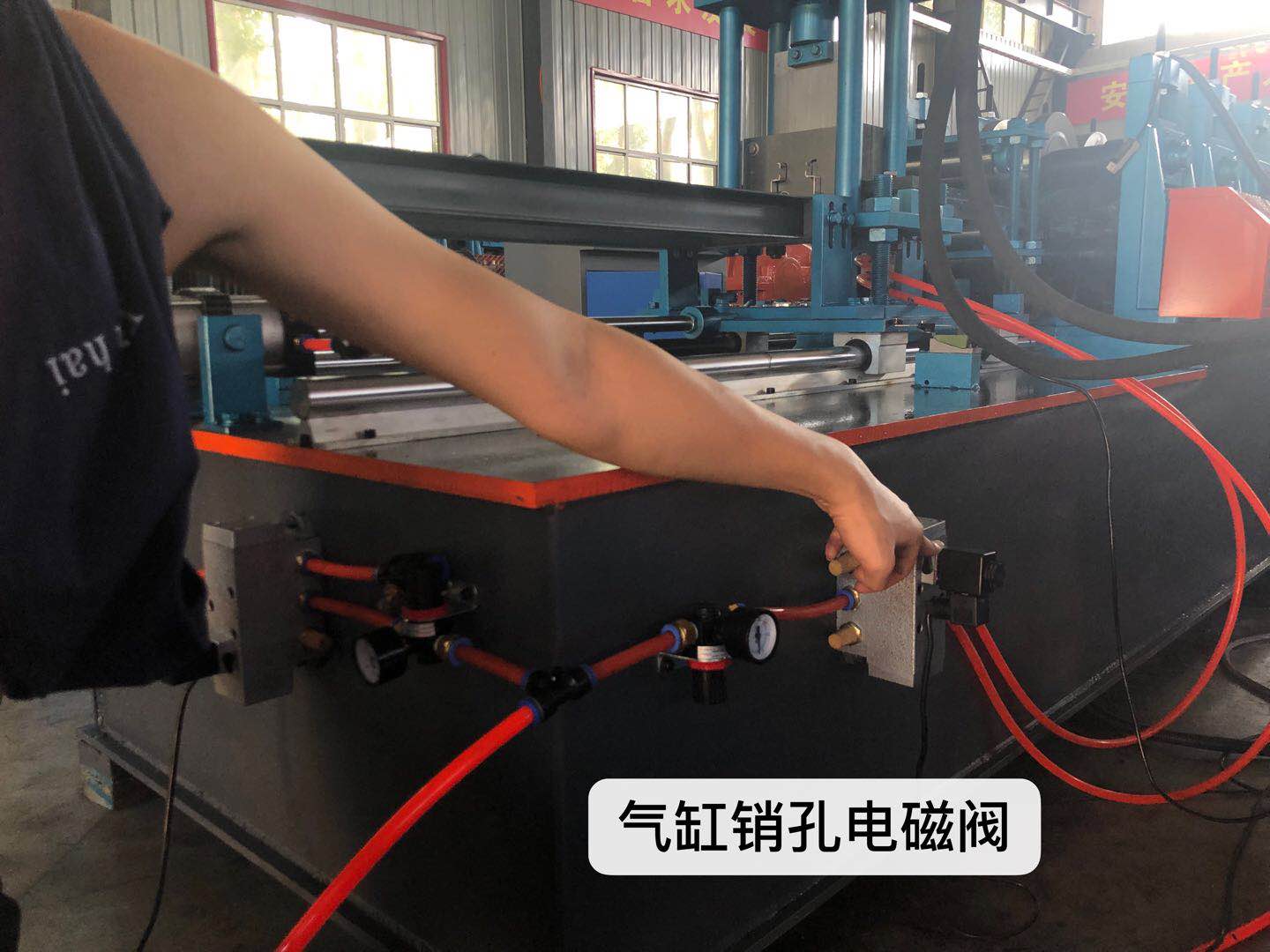

Once the machine is inspected and aligned, the next step is to adjust the settings according to the specifications of the right channel profile being produced. This includes setting the correct roll gap, speed, and material feed rate. Each of these settings plays a critical role in the quality of the final product. If the gap between rollers is too tight, it can cause material deformation or damage; if too loose, it may lead to improper shaping. Adjust the speed according to the material thickness and type to maintain optimal performance.

4. Testing the Output

After completing the above steps, the final part of the debugging process is to test the output of the roll forming machine. Run a small batch of materials through the machine while closely monitoring the right channel profiles as they are produced. Check for any inconsistencies in shape, size, or surface finish. If any issues arise, go back to the previous steps to readjust and refine settings, recheck alignments, or inspect components.

Conclusion

Debugging a right channel roll forming machine is essential for ensuring quality production, reducing downtime, and facilitating smooth operations. By following these simple steps—inspecting components, checking alignment, adjusting settings, and testing output—operators can effectively troubleshoot and resolve issues. A proactive approach to debugging not only maximizes machine performance but also contributes to better product quality and operational efficiency. Ultimately, a well-maintained and properly debugged roll forming machine is key to achieving success in manufacturing processes that rely on precision and consistency.