Understanding the Simple Cut-to-Length Line An Overview

In the manufacturing and processing industries, efficient material handling and production processes are essential for maintaining productivity and minimizing costs. One such method that has gained significant traction is the simple cut-to-length line. This article explores the concept, components, advantages, and applications of cut-to-length lines, focusing on their role in optimizing operations across various sectors.

What is a Cut-to-Length Line?

A cut-to-length line is an automated system designed to cut raw materials, such as metal, plastic, or wood, to specified lengths. Unlike traditional cutting methods, which may involve manual labor and time-consuming setups, cut-to-length lines streamline the process and enhance precision. These systems are particularly effective for industries where uniform length and high throughput are crucial.

The basic principle behind a cut-to-length line involves feeding a continuous roll of material through a series of machines that feed, cut, and stack the material based on predetermined lengths. This reduces waste and ensures that the final product meets specific requirements.

Key Components of a Cut-to-Length Line

1. Uncoiler This is the first station in the cut-to-length line. It is responsible for unwinding the raw material from coils. Uncoilers ensure a smooth and controlled flow of material to the subsequent processing stages.

2. Leveling Machine After the material is uncoiled, it often requires leveling to eliminate any inherent curvature or distortion. Leveling machines apply even pressure to the metal sheets or strips, ensuring uniformity before cutting.

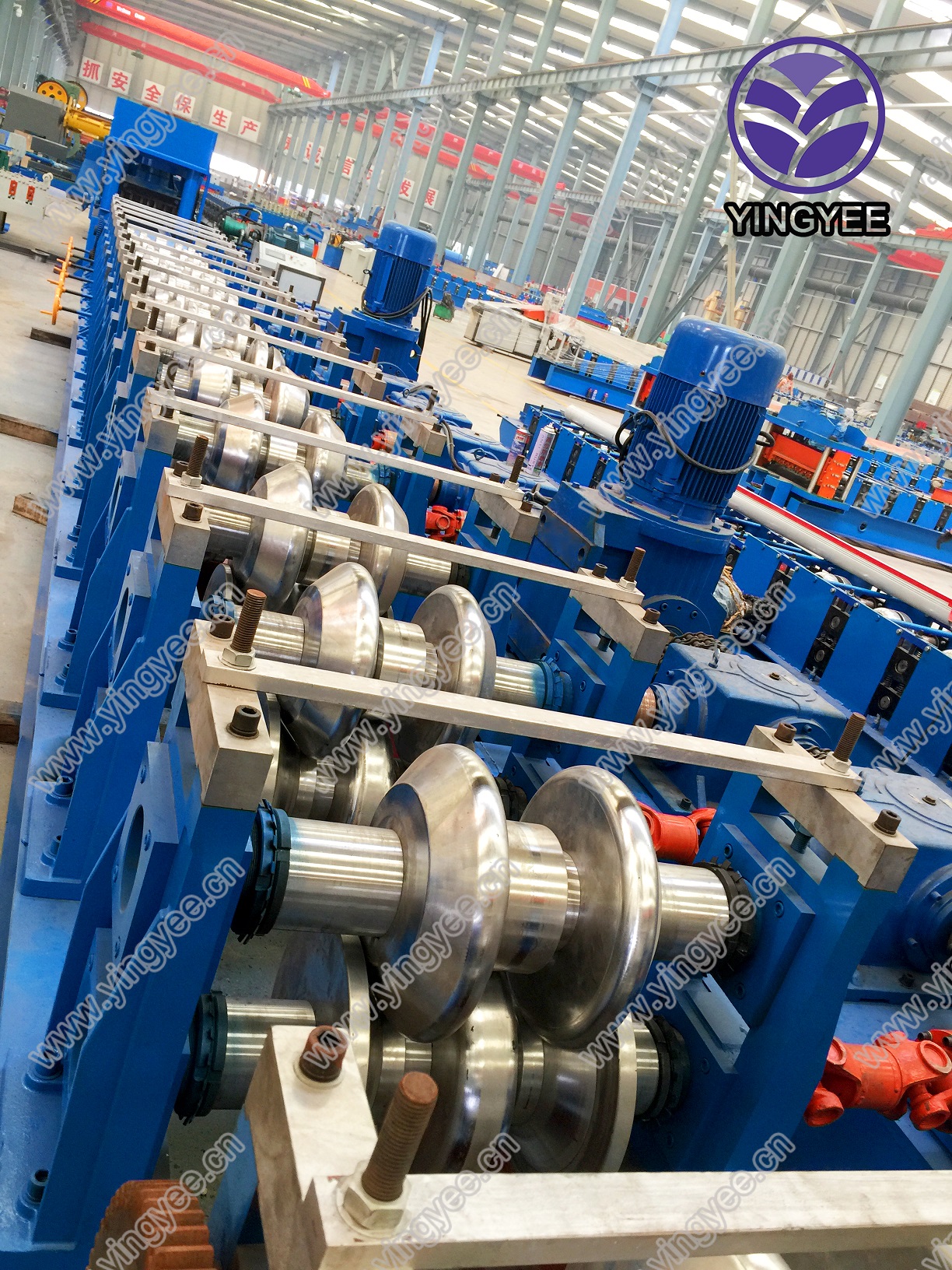

3. Cutting Unit This is the core of the cut-to-length line. The cutting unit precisely cuts the material into the desired lengths using various mechanisms, such as shear cutting or rotary cutting. Modern cutting units often employ advanced technologies, including laser and plasma cutting, to enhance precision and reduce cycle times.

4. Stacker Once cut, the individual lengths are transported to a stacking unit, which organizes and prepares the cut pieces for further handling or packaging. Automated stacking systems can adjust to various stack heights and orientations, improving overall efficiency.

5. Control System A central control system manages the entire process, ensuring synchronization between different components and enabling operators to adjust settings as needed. This system can often be integrated with broader manufacturing execution systems (MES) for real-time monitoring and data collection.

Advantages of Using a Cut-to-Length Line

The implementation of a simple cut-to-length line offers several advantages to manufacturers

- Increased Efficiency Automation reduces the time needed for material handling and processing, allowing for faster production rates. This efficiency helps manufacturers meet tight deadlines and respond to market demands more effectively.

- Reduced Waste By cutting materials to exact lengths, manufacturers can significantly minimize scrap and waste

. This not only saves costs on raw materials but also promotes sustainability within operations.- Improved Quality Precision cutting ensures consistent product quality. Uniform lengths help maintain the integrity of the final product, which is particularly important in industries such as automotive and aerospace.

- Flexibility Modern cut-to-length lines can accommodate a wide range of materials and thicknesses, making them versatile for various production needs. Operators can quickly adjust settings for different product specifications without significant downtime.

Applications of Cut-to-Length Lines

Cut-to-length lines are widely used across various sectors

- Metal Fabrication In metalworking industries, cut-to-length lines are essential for processing sheets and strips of steel, aluminum, and other metals into usable lengths for further fabrication.

- Wood Processing The lumber industry utilizes cut-to-length lines for cutting logs and lumber into specific sizes, facilitating efficient handling and milling.

- Plastic Manufacturing Plastic sheets and rolls can also be processed using cut-to-length systems, catering to industries such as packaging or automotive production.

In conclusion, simple cut-to-length lines play a vital role in enhancing the efficiency and effectiveness of material processing in various industries. Their key components work in harmony to ensure precision and productivity, making them an invaluable asset for manufacturers aiming to optimize their operations. As technology continues to evolve, we can expect further innovations in cut-to-length systems, driving even greater efficiencies in the future.