The shelf storage rack roll forming machine is revolutionizing storage solutions across various industries by combining advanced technology with robust design. Being at the forefront of storage innovation, these machines exemplify the perfect balance of expertise, reliability, and efficiency in metal forming processes.

Roll forming machines dedicated to shelf storage racks are engineered to deliver unmatched precision and consistency in the production of metal shelving units. These machines excel in crafting versatile storage solutions, catering to a wide range of industrial needs—from warehousing and retail to domestic storage. The comprehensive design enhances both operational stability and shelf life of the storage racks they produce, ensuring long-term durability.

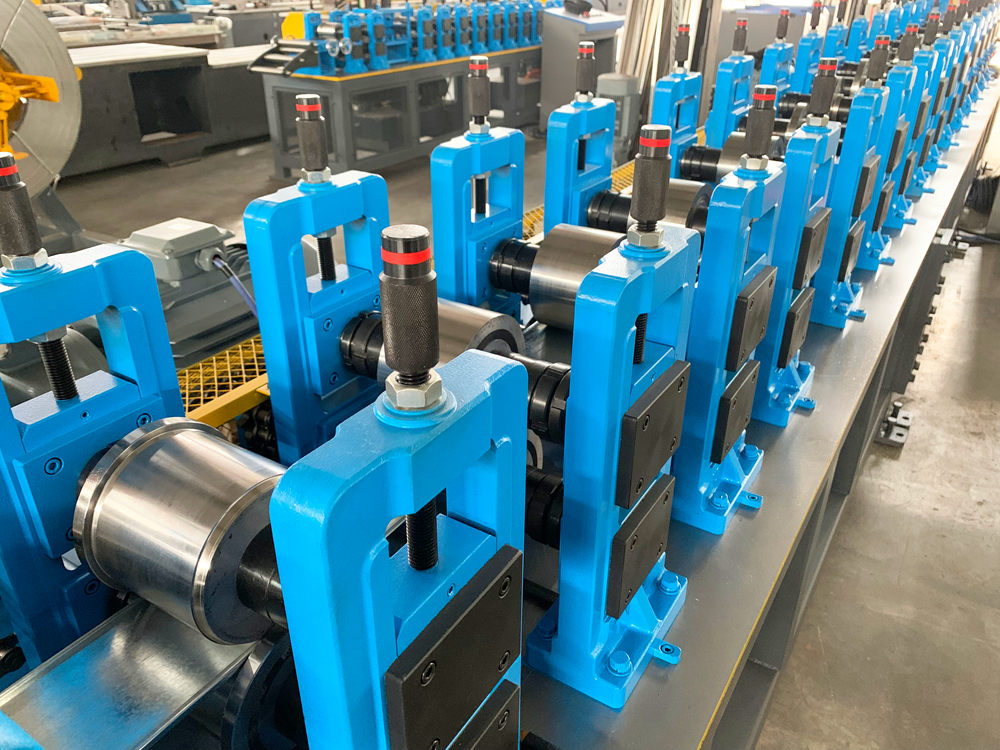

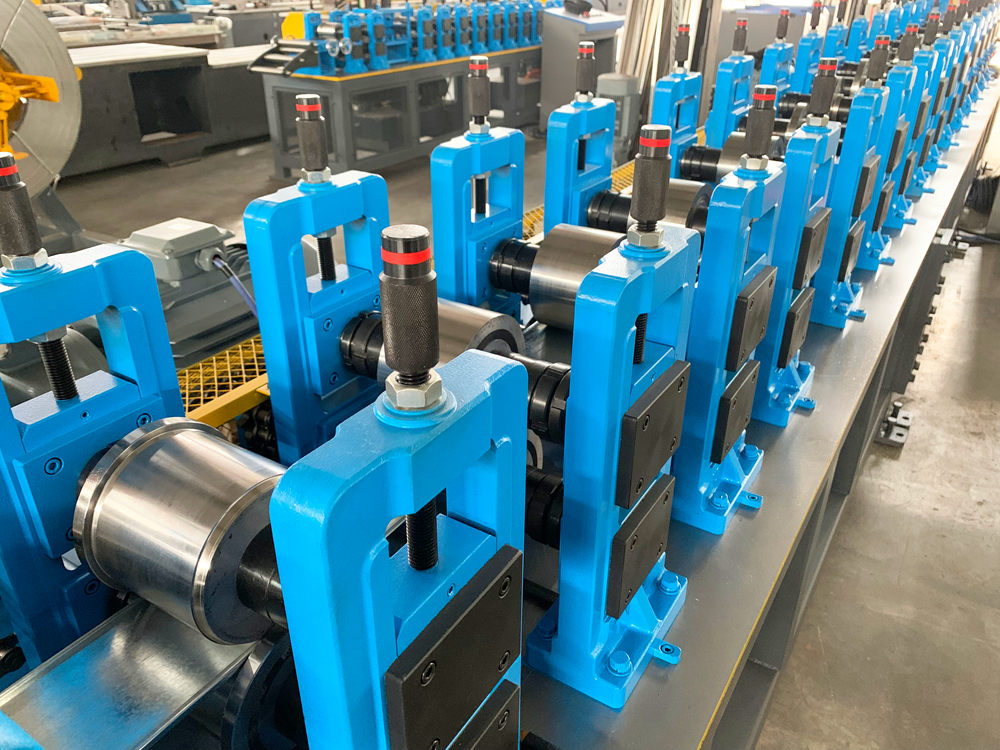

In-depth understanding in the field of roll forming is essential to grasp the full potential of these machines. Typically, they come equipped with a series of precision rollers that continually shape metal coils into desired forms. These machines have automated controls that adjust parameters like speed, angle, and pressure to achieve precise cuts and bends, thus creating perfectly formed shelving components every single time. This automated precision is critical, as it minimizes human error and significantly boosts productivity.

Beyond the technical aspects,

the impact of roll forming machines on logistical operations is notably profound. By providing a reliable means to produce high-quality storage racks, these machines play a pivotal role in optimizing space utilization. Implementing such storage solutions allows businesses to maximize their inventory management efficiency, directly translating into cost savings and improved operational workflows.

Manufacturers of shelf storage rack roll forming machines integrate cutting-edge technology to ensure these machines remain on the leading edge of innovations in the storage sector. Through continual research and development, these machines are now capable of producing racks with complex configurations and custom dimensions—meeting the growing demands for flexibility in storage systems. This adaptability is crucial for businesses that require tailored solutions to align with evolving storage strategies.

shelf storage rack roll forming machine

Furthermore, the authority of these machines in the market is reinforced by their adherence to stringent industry standards for safety and quality. Reputable manufacturers conduct rigorous testing and quality assurance processes to ensure each roll forming machine delivers consistent performance whilst minimizing the risk of operational failures. This adherence not only boosts trust among users but also enhances the safety metrics of industrial environments employing these machines.

Trustworthiness is further enhanced by the comprehensive support and service networks that backing manufacturers provide. This includes detailed user manuals, training programs, and responsive customer service—ensuring users can seamlessly integrate these machines into their production lines. Such support alleviates implementation challenges and helps maintain the longevity and efficiency of the roll forming machines.

In terms of sustainability, modern shelf storage rack roll forming machines are designed with eco-efficiency in mind. Energy-efficient motors and reduced material waste processes align with global sustainability goals, providing environmentally friendly production solutions without compromising performance.

In conclusion, the expertise, authority, and trust vested in shelf storage rack roll forming machines underscore their indispensable role in modern storage system manufacturing. By marrying technological advancements with industrial experience, these machines serve as reliable pillars in optimizing storage solutions across diverse sectors. Businesses leveraging these machines lay the groundwork for improved efficiency, enhanced safety, and greater adaptability in storage management—a testament to the value these roll forming machines bring to the table.