The Shelf Rack Upright Roll Forming Machine Revolutionizing Storage Solutions

In today's fast-paced industrial landscape, efficient storage solutions are paramount for businesses seeking to optimize their operational capabilities. One such solution that has gained significant traction is the shelf rack upright roll forming machine. This innovative equipment is designed to create high-quality shelf rack components, which are crucial for organizing and maximizing space in warehouses, retail environments, and manufacturing facilities.

Understanding Roll Forming Technology

Roll forming is a manufacturing process that involves feeding a long strip of metal—often steel—through a series of rolls to progressively shape it into a desired profile. This method is highly efficient and yields consistent quality, making it particularly suited for producing components like shelf rack uprights. These uprights serve as the vertical supports in shelving systems, providing the backbone for all shelving units and ensuring structural integrity.

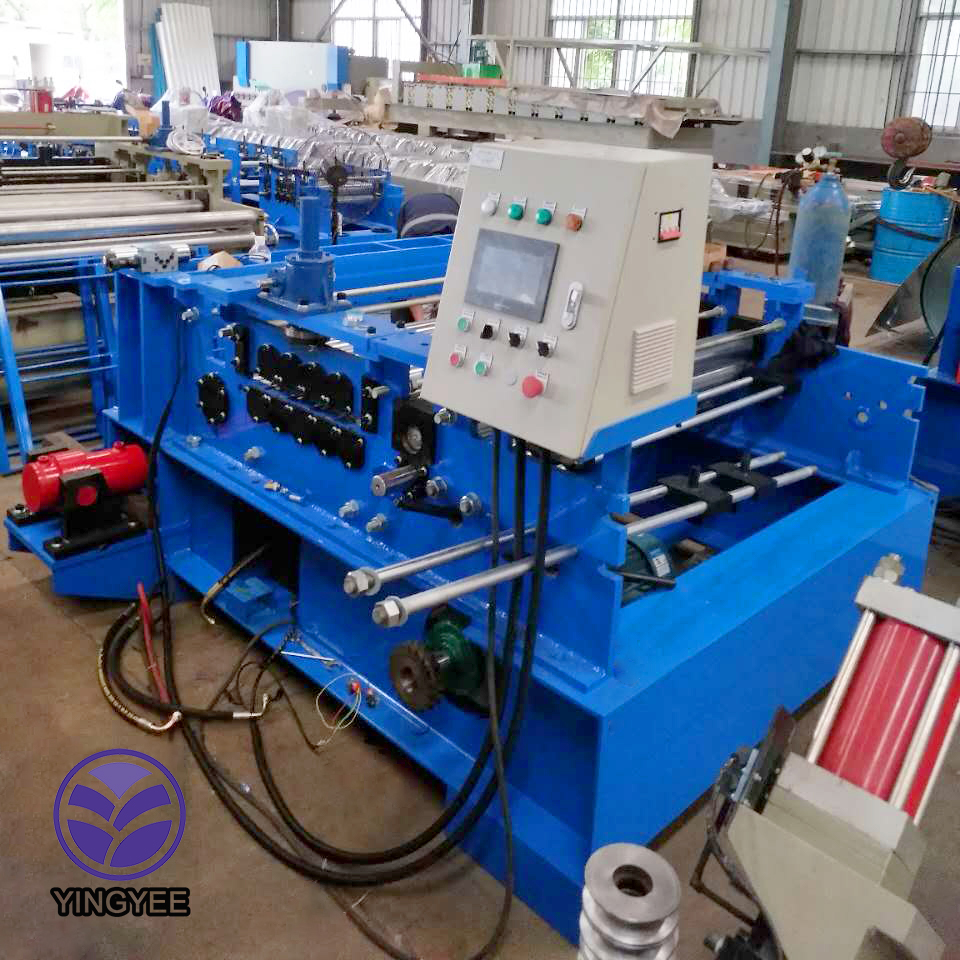

The shelf rack upright roll forming machine is equipped with multiple roll stations, each designed to perform a specific shaping function. By carefully adjusting the roll alignment and pressure, manufacturers can create complex profiles that enhance the strength and functionality of the finished product. The precision of this process is critical; even minor discrepancies can affect the overall stability and load-bearing capacity of the shelving system.

Key Features and Benefits

1. High Production Efficiency One of the standout features of shelf rack upright roll forming machines is their speed. These machines can produce a significant volume of uprights in a short amount of time, reducing lead times and improving overall productivity. This efficiency is vital for businesses that require rapid turnaround times and consistent output.

2. Customization and Flexibility Every business has unique requirements when it comes to storage solutions. These roll forming machines can be customized to produce uprights of various sizes, shapes, and materials, allowing manufacturers to cater to specific client needs. This flexibility empowers businesses to adapt to changing market demands without incurring substantial retooling costs.

3. Cost-Effectiveness Although the initial investment in a shelf rack upright roll forming machine may seem substantial, the long-term savings often outweigh the costs. The efficient use of materials minimizes waste, and the high production rates lead to lower labor costs. Additionally, the durability of roll-formed components reduces replacement and maintenance expenses over time.

4. Quality and Durability The roll forming process results in a uniform structure that enhances the strength and durability of shelf rack uprights. As these components are subjected to significant loads, their robustness is essential for ensuring safety in storage applications. Moreover, the consistency achieved through automation leads to fewer defects and higher product quality.

5. Ease of Operation Modern shelf rack upright roll forming machines are designed with user-friendliness in mind. Advanced control systems often allow for easy adjustments and monitoring, making the operation intuitive, even for those with limited technical expertise. This ease of use can lead to reduced training time and increased operator efficiency.

Conclusion

The introduction of the shelf rack upright roll forming machine has transformed the way manufacturers approach storage solutions. Its ability to produce high-quality, customizable components quickly and cost-effectively has made it a vital asset in various industries. As businesses continue to seek ways to optimize their storage capabilities, the role of roll forming technology in creating reliable shelf racks is only expected to grow. By investing in such machinery, companies can enhance their operational efficiency, reduce overhead costs, and ultimately improve their bottom line. As the demand for organized, functional spaces rises, the shelf rack upright roll forming machine stands as a testament to innovation in manufacturing technology.