The Evolution and Importance of Shelf Rack Upright Roll Forming Machines

In the fast-paced world of manufacturing and logistics, efficiency and precision have become paramount. One of the unsung heroes of this revolution is the shelf rack upright roll forming machine. This innovative piece of equipment has transformed the way shelf racks are produced, optimizing both space and resources. In this article, we will explore the functionality, advantages, and future prospects of these machines.

What is a Shelf Rack Upright Roll Forming Machine?

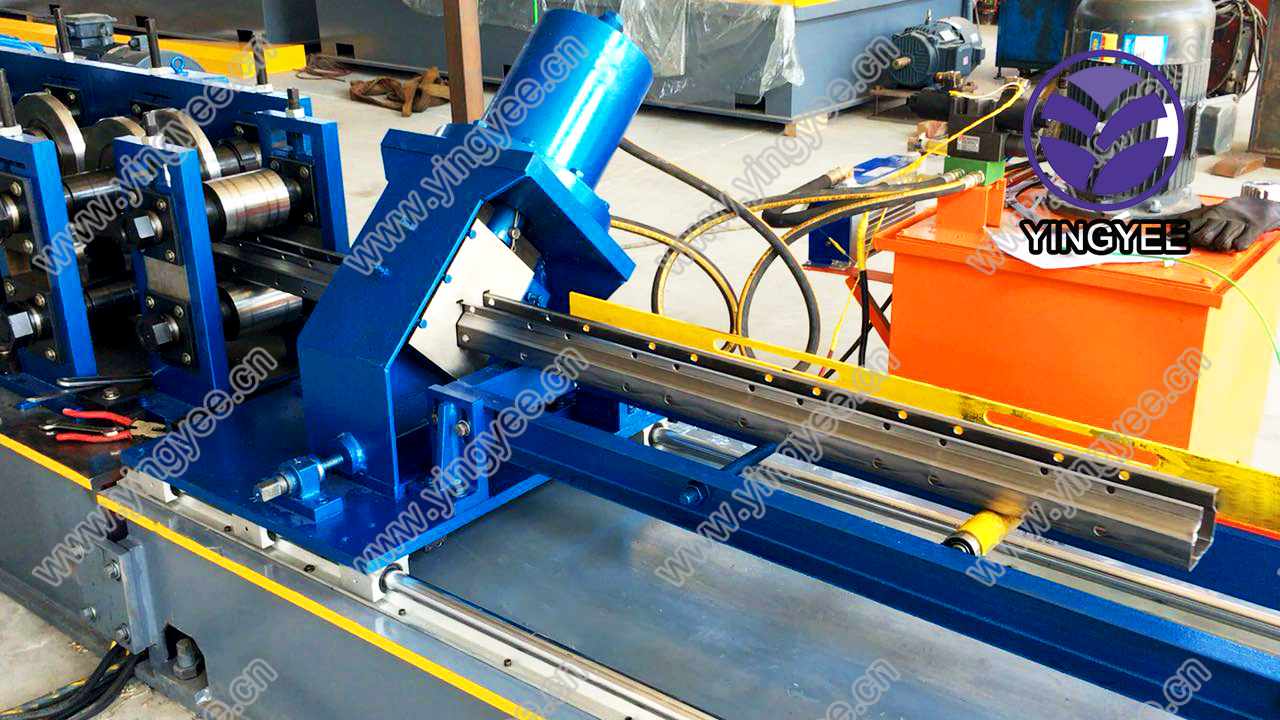

At its core, a shelf rack upright roll forming machine is designed to create upright supports for shelving systems. These machines work by continuously feeding metal coils through a series of rolls that shape the material into desired profiles. The result is a strong, durable frame that can support heavy loads, making it ideal for warehouses, retail settings, and storage facilities.

The Manufacturing Process

The process begins with raw metal coils, typically made of steel or aluminum. These coils are fed into the machine, where they are progressively shaped through various roll stations. Each station adds a specific contour or bend, ultimately forming the upright sections of the rack. After shaping, the material can be cut to size automatically, allowing for high precision and consistent quality.

This method of production significantly enhances the speed of manufacturing. Unlike traditional methods, which may involve cutting and welding, roll forming provides a continuous and automated approach. This not only saves time but also reduces labor costs and minimizes material waste.

Advantages of Using Roll Forming Machines

1. Cost-Effectiveness One of the primary advantages of shelf rack upright roll forming machines is their cost efficiency. By reducing labor and material waste, manufacturers can produce high-quality shelves at a lower cost.

2. Durability and Strength The roll-formed steel profiles offer superior strength compared to those made through welding or other methods. This is crucial for rack systems that need to support heavy items without bending or breaking.

3. Customization These machines can be easily adjusted to create different sizes and shapes, allowing manufacturers to cater to specific client needs. This flexibility is vital in an industry where diverse storage requirements are common.

4. Automated Production Modern roll forming machines are often equipped with advanced automation technologies. This leads to greater efficiency, reduced human error, and higher output rates.

5. Environmental Impact Minimizing waste in the manufacturing process also contributes to sustainability. Roll forming allows for the maximum use of raw materials, making it a more environmentally friendly option compared to traditional methods.

The Future of Shelf Rack Upright Roll Forming Machines

As industries evolve, so do the technologies behind them. The future of shelf rack upright roll forming machines looks promising, with advancements in automation and smart manufacturing on the horizon. The integration of artificial intelligence and machine learning is paving the way for machines that can self-optimize for efficiency. Such innovations may enable manufacturers to predict maintenance needs, further reducing downtime and increasing productivity.

Moreover, with the growing emphasis on sustainability, manufacturers are increasingly seeking solutions that minimize environmental impact. Roll forming machines, with their efficient use of materials and energy, are well-positioned to adapt to these changing demands.

Conclusion

In conclusion, shelf rack upright roll forming machines play a crucial role in modern manufacturing, particularly in sectors where storage solutions are essential. Their ability to produce strong, durable, and cost-effective shelving units makes them indispensable. As technology continues to advance, we can expect even greater improvements in efficiency and sustainability, solidifying the importance of these machines in the future of manufacturing and logistics. By embracing innovation, the industry can ensure that it meets the growing demands of an evolving marketplace while maintaining high standards of quality and performance.