The Evolution of Sheet Roll Forming Machines

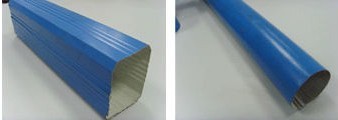

The sheet roll forming machine is a vital piece of equipment in modern manufacturing, especially in industries like construction, automotive, and appliances. This machine is designed to transform flat metal sheets into specific profiles by passing them through a series of rollers. The process provides high precision, excellent surface finish, and the ability to create complex shapes, making it an indispensable tool for producing components like roofing sheets, wall panels, and metal framing.

The history of roll forming technology dates back to the early 20th century when manufacturers sought more efficient ways to create metal products. Originally, the process was labor-intensive and required significant manual intervention. However, advancements in technology and engineering have transformed sheet roll forming machines into highly automated systems capable of operating with precision and speed.

One of the primary advantages of sheet roll forming machines is their ability to produce long lengths of uniform profiles with minimal waste. This not only reduces material costs but also enhances production efficiency. Modern machines can be tailored to produce a wide variety of shapes and sizes, catering to the specific needs of different industries. With the integration of computer numerical control (CNC) technology, manufacturers can achieve precise specifications, reducing errors and improving overall product quality.

The versatility of sheet roll forming machines extends beyond just material handling. They can work with various metals, including steel, aluminum, and other alloys, which allows manufacturers to choose the most suitable material for their products. Moreover, these machines can be integrated into automated production lines, further enhancing efficiency and reducing labor costs.

Despite their benefits, manufacturers must also consider the challenges associated with sheet roll forming. Proper maintenance and periodic inspections are crucial to ensure the longevity and performance of the machines. Additionally, operators need to be well-trained to manage the complexities of modern roll forming processes, ensuring that production runs smoothly and safely.

In conclusion, sheet roll forming machines have revolutionized the way metal products are manufactured. Their ability to produce high-quality, precisely shaped components with minimal waste has made them essential in various industries. As technology continues to advance, we can expect to see even greater innovations in roll forming, further enhancing the capabilities and efficiency of these machines. The future looks promising, as manufacturers continue to explore new materials and processes that will shape the landscape of metalworking for years to come.