Servo Control Feeding Storage Racking Forming Machine Revolutionizing Manufacturing Processes

In today's rapidly evolving industrial landscape, manufacturers constantly seek innovative solutions to enhance production efficiency and reduce operational costs. One such breakthrough technology is the servo control feeding storage racking forming machine, a state-of-the-art system designed to streamline the manufacturing process. This advanced machine integrates servo control technology with feeding, storage, and racking capabilities, transforming the way materials are handled and processed in various industries.

Understanding the Technology

At its core, the servo control system employs motors that are highly responsive and precise, allowing for accurate movement and positioning of materials. Unlike traditional systems that rely on pneumatic or hydraulic controls, servo systems offer greater efficiency and flexibility. This precision is crucial in manufacturing environments where even minor deviations can result in significant errors or waste.

The feeding mechanism in the servo-controlled machine plays a vital role in synchronizing the flow of materials into the production line. With the integration of advanced sensors and feedback systems, the feeder can automatically adjust its speed and position based on real-time data. This ensures that materials are delivered consistently and accurately to the forming section of the machine.

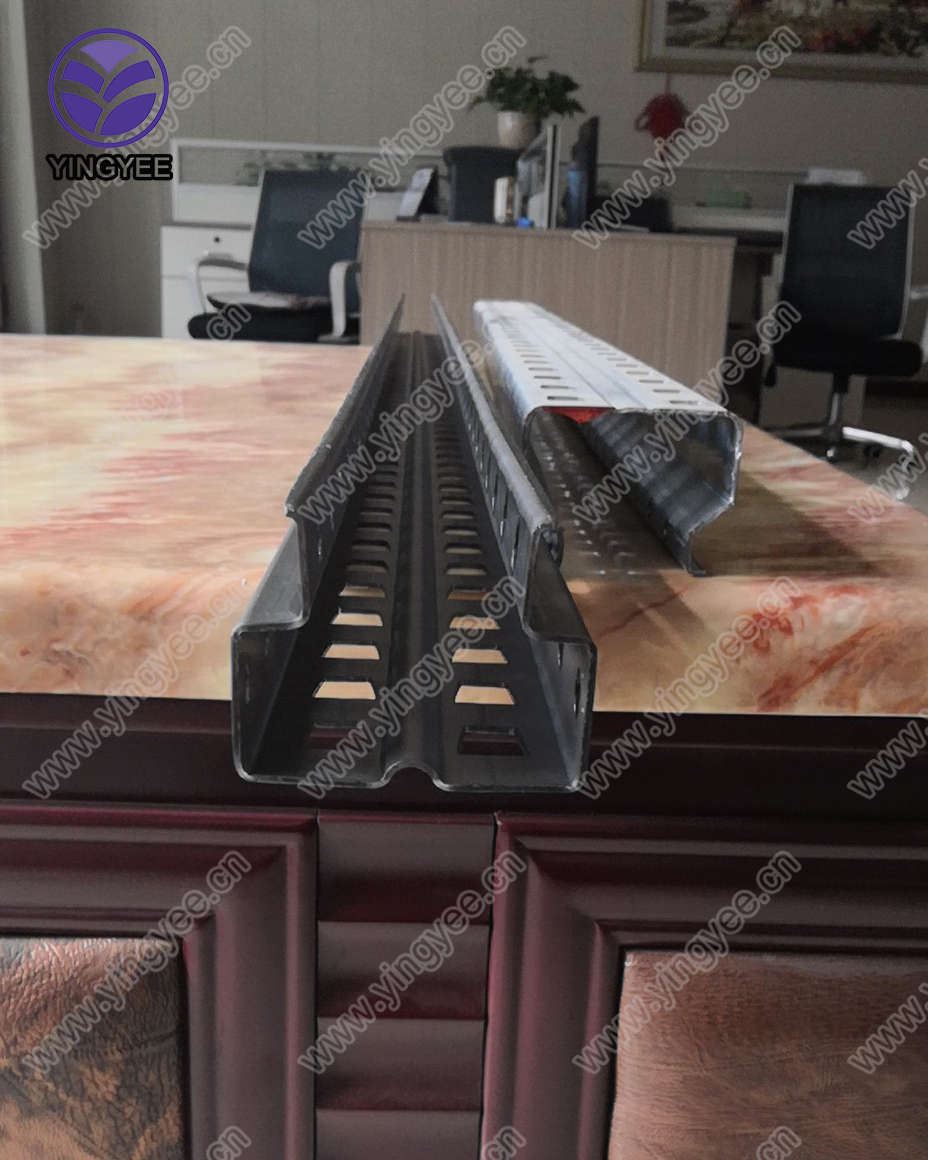

Storage capabilities are another critical aspect of this technology. The machine is designed with smart racking systems that optimize space utilization while maintaining easy access to the required materials. These racking systems can be configured to accommodate various types of materials, including sheets, coils, and other components, making it highly versatile for different manufacturing applications.

Benefits of Servo Control Feeding Storage Racking Forming Machines

1. Increased Efficiency The automation of feeding and storage processes significantly reduces manual intervention, which minimizes downtime and increases throughput. By automating material handling, manufacturers can achieve faster production cycles, ultimately leading to higher output and profitability.

2. Precision and Accuracy Servo control technology allows for highly precise positioning and consistent material delivery, reducing the likelihood of errors in the manufacturing process. This precision is particularly essential in industries that require tight tolerances and high-quality standards, such as automotive and aerospace manufacturing.

3. Flexibility and Adaptability The modular design of these machines enables manufacturers to easily adapt to changes in production needs. Whether adjusting for different product sizes or switching between materials, the servo control feeding system can be quickly configured to meet evolving demands.

4. Space Optimization The integrated racking and storage solutions help maximize available warehouse space, reducing the footprint of the manufacturing operation. By minimizing the area required for material storage, companies can allocate resources more effectively, leading to further cost savings.

5. Reduced Labor Costs With automation taking over labor-intensive tasks, manufacturers can reallocate their workforce to more value-added activities. This shift not only enhances overall productivity but also helps in skill development and job satisfaction for employees.

Future Prospects

As industries continue to embrace automation and smart technologies, the demand for servo control feeding storage racking forming machines is expected to grow. With advancements in IoT (Internet of Things) and AI (Artificial Intelligence), future iterations of these machines could further enhance their capabilities through predictive maintenance, enhanced data analytics, and real-time monitoring, allowing manufacturers to stay ahead of the competition.

In conclusion, the servo control feeding storage racking forming machine represents a significant advancement in the manufacturing sector. By integrating precision servo technology with efficient feeding and storage solutions, this innovative machine not only optimizes production processes but also provides manufacturers with a competitive edge in an increasingly demanding market. As technology continues to advance, these machines will play an integral role in shaping the future of manufacturing, paving the way for smarter, more efficient operations.