The integration of servo control technology in feeding, storage, racking, forming machines has revolutionized the manufacturing industry. Servo control systems offer precision, efficiency, and flexibility that traditional mechanisms lack. This advancement is not just a technical upgrade but a paradigm shift towards smarter and automated production processes.

In feeding operations, servo control systems provide accurate positioning and speed regulation for materials moving through production lines. The ability to fine-tune movements ensures that materials are handled with minimal waste and maximum efficiency. For instance, in an assembly line where components must be fed into a machine at precise intervals, servo motors can adjust their speed and timing based on real-time data, optimizing the process and reducing downtime.

Storage and retrieval systems have also benefited significantly from servo controls. Automated warehouses use servo-driven racking systems to store and retrieve goods with unparalleled accuracy and speed. These systems can handle a wide variety of products, from small parts to large pallets, without compromising safety or efficiency. The servo motors' smooth operation and precise control reduce wear and tear on machinery and increase the longevity of the equipment.

Racking systems in particular rely on servo motors to manage the complex movements required to access stored items

Racking systems in particular rely on servo motors to manage the complex movements required to access stored items

Racking systems in particular rely on servo motors to manage the complex movements required to access stored items

Racking systems in particular rely on servo motors to manage the complex movements required to access stored items

servo control feeding storage racking forming machine

servo control feeding storage racking forming machine. With servo control, these systems can perform rapid yet gentle handling of products, reducing damage and allowing for more efficient use of space within the warehouse.

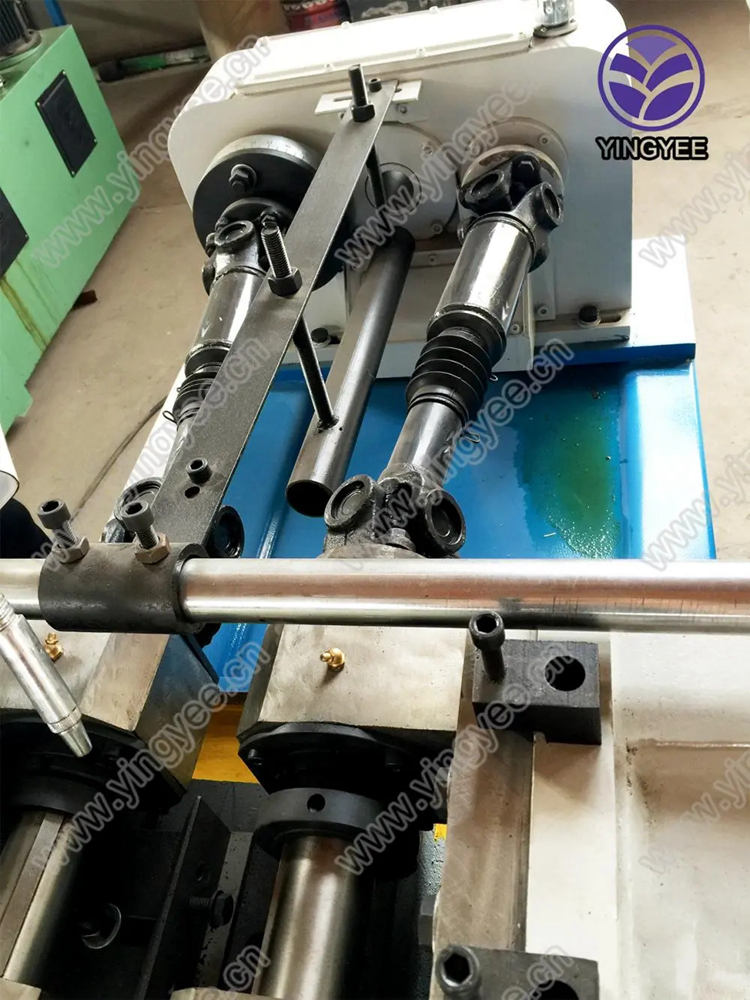

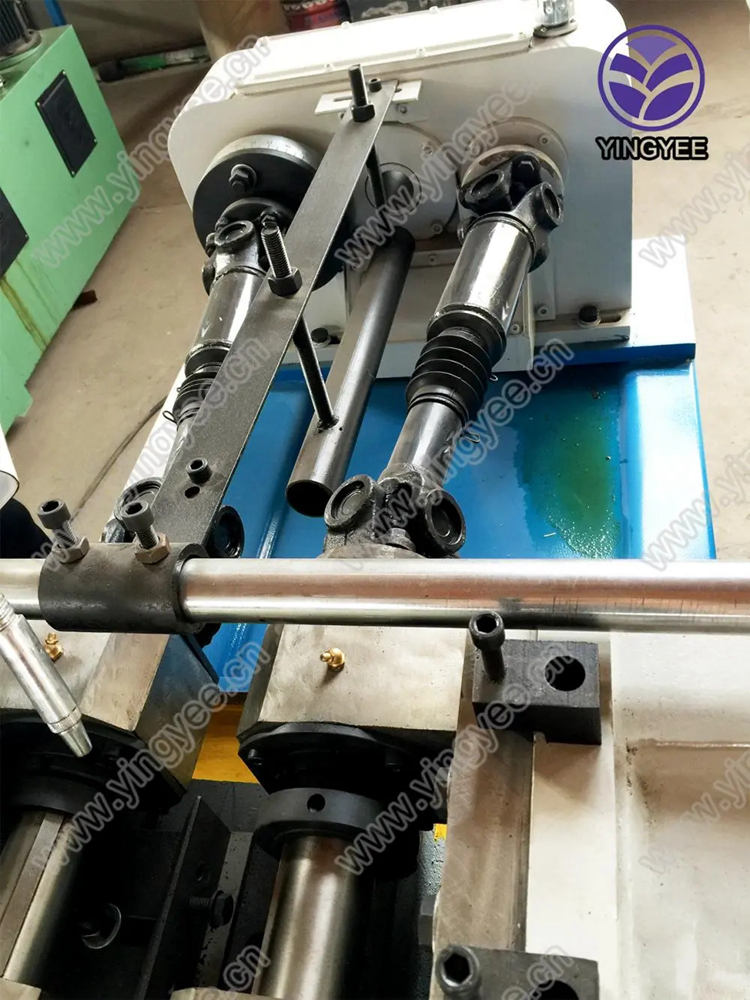

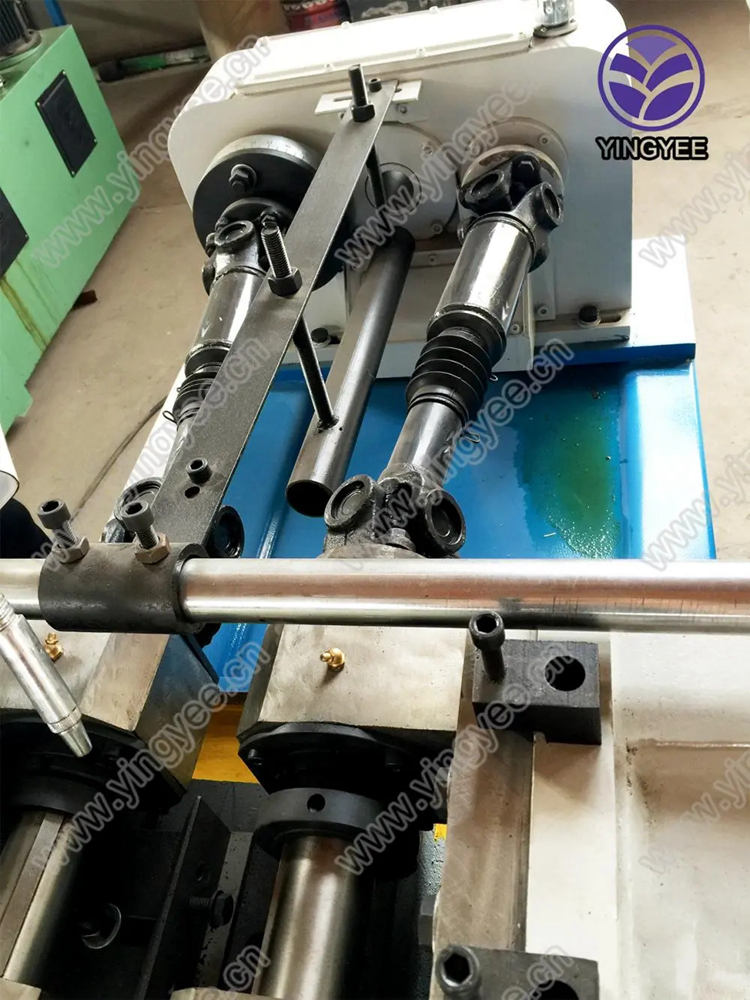

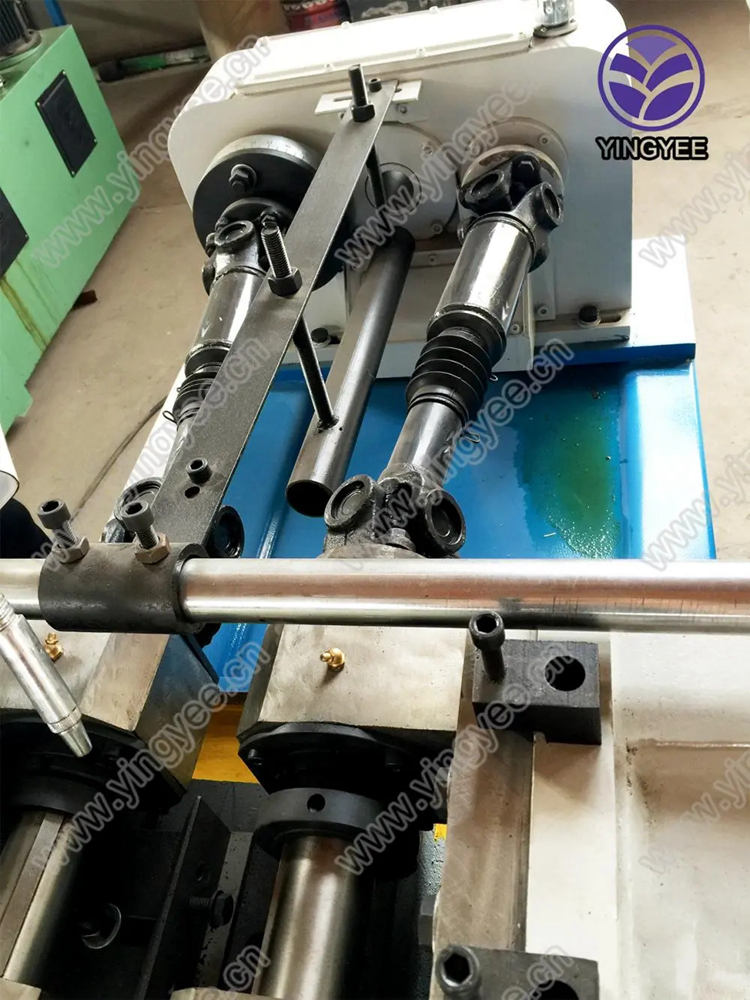

In forming machines used in industries such as metalworking and plastic molding, servo control technology enables intricate shaping with high precision. Forming machines equipped with servo motors can apply exactly the right amount of force at just the right moment, resulting in consistent product quality and reduced material waste. The adjustments can be made instantaneously, responding to variations in material thickness or other factors that might affect the forming process.

Furthermore, servo control systems often come with advanced diagnostic tools that can monitor machine health and performance in real-time. This predictive maintenance feature helps manufacturers detect potential issues before they become costly problems, ensuring continuous operation and reducing maintenance costs.

In conclusion, the application of servo control technology in feeding, storage, racking, and forming machines enhances operational efficiency, product quality, and system reliability. As we move toward increasingly automated and intelligent manufacturing environments, servo control systems will undoubtedly continue to play a pivotal role in driving innovation and productivity.

Racking systems in particular rely on servo motors to manage the complex movements required to access stored items

Racking systems in particular rely on servo motors to manage the complex movements required to access stored items

Racking systems in particular rely on servo motors to manage the complex movements required to access stored items

Racking systems in particular rely on servo motors to manage the complex movements required to access stored items servo control feeding storage racking forming machine. With servo control, these systems can perform rapid yet gentle handling of products, reducing damage and allowing for more efficient use of space within the warehouse.

In forming machines used in industries such as metalworking and plastic molding, servo control technology enables intricate shaping with high precision. Forming machines equipped with servo motors can apply exactly the right amount of force at just the right moment, resulting in consistent product quality and reduced material waste. The adjustments can be made instantaneously, responding to variations in material thickness or other factors that might affect the forming process.

Furthermore, servo control systems often come with advanced diagnostic tools that can monitor machine health and performance in real-time. This predictive maintenance feature helps manufacturers detect potential issues before they become costly problems, ensuring continuous operation and reducing maintenance costs.

In conclusion, the application of servo control technology in feeding, storage, racking, and forming machines enhances operational efficiency, product quality, and system reliability. As we move toward increasingly automated and intelligent manufacturing environments, servo control systems will undoubtedly continue to play a pivotal role in driving innovation and productivity.

servo control feeding storage racking forming machine. With servo control, these systems can perform rapid yet gentle handling of products, reducing damage and allowing for more efficient use of space within the warehouse.

In forming machines used in industries such as metalworking and plastic molding, servo control technology enables intricate shaping with high precision. Forming machines equipped with servo motors can apply exactly the right amount of force at just the right moment, resulting in consistent product quality and reduced material waste. The adjustments can be made instantaneously, responding to variations in material thickness or other factors that might affect the forming process.

Furthermore, servo control systems often come with advanced diagnostic tools that can monitor machine health and performance in real-time. This predictive maintenance feature helps manufacturers detect potential issues before they become costly problems, ensuring continuous operation and reducing maintenance costs.

In conclusion, the application of servo control technology in feeding, storage, racking, and forming machines enhances operational efficiency, product quality, and system reliability. As we move toward increasingly automated and intelligent manufacturing environments, servo control systems will undoubtedly continue to play a pivotal role in driving innovation and productivity.