Understanding Sandwich Panel Roll Forming Machines

In the modern construction industry, the demand for building materials that offer both durability and energy efficiency has led to the popularization of sandwich panels. These panels consist of two outer layers and a core that provides insulation, making them an ideal choice for various applications, including warehouses, factories, and even residential buildings. To produce these panels efficiently, manufacturers rely on sandwich panel roll forming machines.

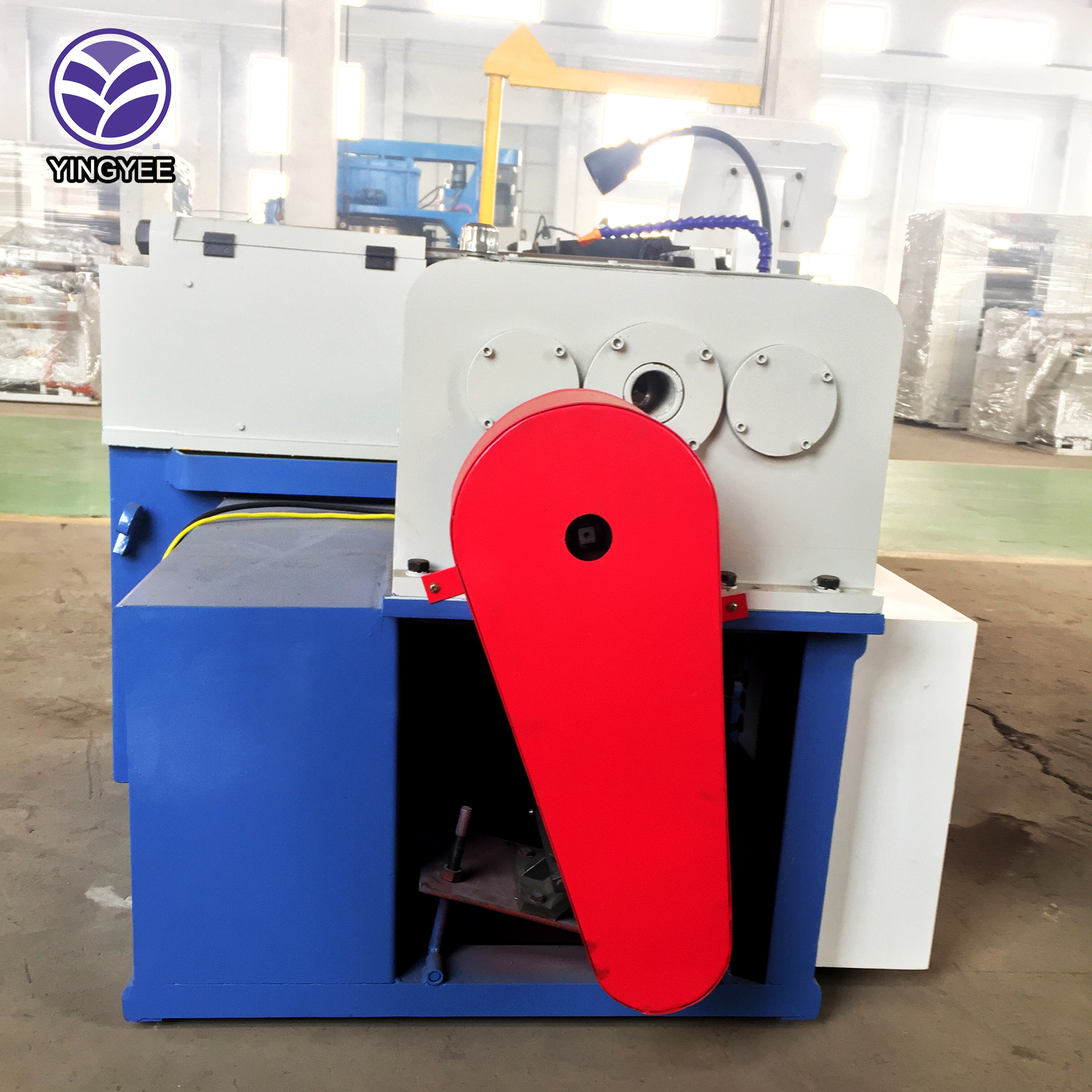

What is a Sandwich Panel Roll Forming Machine?

A sandwich panel roll forming machine is a specialized piece of equipment that creates sandwich panels through a continuous process. The machine takes flat metal sheets, which are often pre-coated to enhance their durability and aesthetic appeal, and rolls them into specific shapes to form the outer layers of the panel. Meanwhile, an insulating core material, typically made from polyurethane or polystyrene foam, is added between the two metal sheets. This process ensures the panels maintain structural integrity while offering excellent thermal insulation.

Key Components of the Machine

1. Feeding System This part of the machine is responsible for feeding the raw materials into the forming process. It often features automatic controls to enhance efficiency and reduce labor costs.

2. Roll Forming Station The core of the machine, where metal sheets are shaped into the desired profile. This station comprises various rollers that apply pressure to form the sheets gradually.

3. Cutting System The cutting mechanism usually works in tandem with the roll forming process to produce panels of predetermined lengths. It often uses hydraulic or mechanical systems for precise cuts.

4. Assembly Unit After forming and cutting, the machine assembles the sandwich panel by injecting the insulating core material between the outer layers. This step is crucial for achieving the panel's thermal properties.

5. Control System Modern machines feature advanced control systems equipped with PLC (Programmable Logic Controller) technology, allowing for precise adjustments and monitoring of the production process. This enhances both efficiency and product quality.

Benefits of Sandwich Panel Roll Forming Machines

1. Efficiency and Consistency One of the primary advantages of using roll forming machines is the speed and consistency with which they produce sandwich panels. This efficiency helps manufacturers meet high demands without compromising quality.

2. Customization Roll forming machines can be adjusted to produce a wide variety of panel sizes and shapes, making them highly versatile for different construction needs.

3. Cost-Effectiveness By automating the production process, businesses can reduce labor costs and minimize material waste, ultimately leading to higher profit margins.

4. Enhanced Insulation The combination of metal outer layers and insulated cores means that sandwich panels provide excellent thermal insulation, contributing to energy savings in buildings.

5. Durability Sandwich panels are known for their strength and resistance to environmental factors, such as moisture and temperature fluctuations. This durability makes them ideal for long-term use in various climates.

Conclusion

Sandwich panel roll forming machines represent a significant advancement in manufacturing technology, enhancing the production of energy-efficient building materials. With their ability to produce high-quality sandwich panels quickly and cost-effectively, these machines are transforming the construction landscape. As the industry continues to prioritize sustainability and efficiency, the role of sandwich panel roll forming machines will only grow, shaping the future of modern architecture. By investing in such technology, manufacturers can ensure they meet the increasing demand for innovative building solutions that align with contemporary environmental standards.