Advancements in Round and Square Steel Pipes Forming Machines

In an era where precision and efficiency in industrial manufacturing are paramount, round and square steel pipes forming machines have emerged as critical pieces of equipment in various sectors. These machines play a pivotal role in the fabrication of steel pipes, which are integral components in construction, automotive, and infrastructure development. This article delves into the significance, functionality, and advancements in round and square steel pipes forming machines.

Understanding the Machines

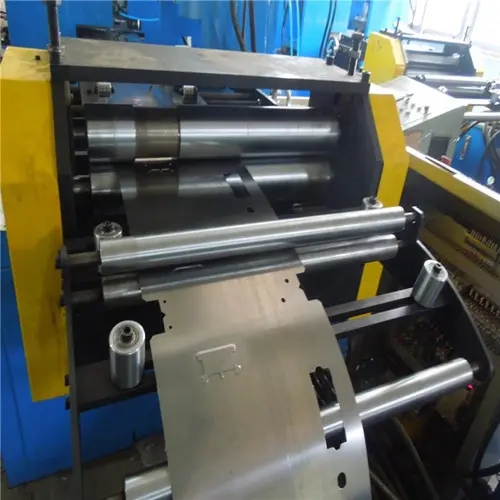

Round and square steel pipes forming machines are designed to transform raw steel strips into finished pipes through processes such as bending, welding, and shaping. These machines utilize advanced technologies to ensure that the pipes achieve the desired dimensions, wall thickness, and structural integrity. The choice between round and square pipes often depends on the application; while round pipes are typically used for fluid transport and structural applications, square pipes are preferred for construction and aesthetic purposes.

Applications and Importance

The applications of round and square steel pipes are extensive. In the construction industry, they are used for framing buildings, creating scaffolding, and developing various structural elements. In the automotive sector, these pipes serve as components for exhaust systems and chassis structures. Moreover, round pipes are instrumental in the oil and gas industries, where they are used for pipelines and transportation of various fluids.

The importance of these machines cannot be overstated. They not only enhance the production capacity of steel manufacturers but also improve the quality and consistency of the products. With rising global demand for steel pipes, particularly in developing economies, the efficiency of forming machines directly influences market competitiveness.

Technological Advancements

Recent innovations in technology have led to significant improvements in the design and functionality of round and square steel pipes forming machines. Modern machines are equipped with advanced Computer Numerical Control (CNC) systems that automate the forming and cutting processes. This automation reduces human error, increases precision, and optimizes production cycles.

Moreover, advancements in material science have introduced high-strength steel materials that can withstand extreme conditions. Forming machines have adapted to work with these new materials, ensuring that the end products meet stringent safety and performance standards.

Another key innovation is the integration of real-time monitoring systems that utilize IoT (Internet of Things) technology. These systems track the performance of machines, providing valuable data that can be used for predictive maintenance and quality control.

Environmental Considerations

As industries move towards greener production methods, the role of forming machines in reducing waste and energy consumption has become increasingly important. Many modern machines are designed to operate with greater energy efficiency and minimal scrap production. Manufacturers are also focusing on the recyclability of the materials used in the pipes, which aligns with global sustainability goals.

Conclusion

Round and square steel pipes forming machines are at the forefront of modern manufacturing technology. Their ability to produce high-quality pipes efficiently and sustainably makes them indispensable in various industries. As technology continues to evolve, we can expect further enhancements in the capabilities of these machines, contributing to improved industrial performance and sustainability.

In summary, the future of round and square steel pipes forming machines looks promising, driven by technological innovations and a growing focus on efficiency and sustainability. As businesses seek to meet the demands of a rapidly changing marketplace, these machines will undoubtedly play a crucial role in shaping the landscape of steel production for years to come.