The Revolution of Roof Tile Making Machines

The construction industry has experienced significant advancements over the years, particularly in manufacturing processes. Among these innovations, roof tile making machines have emerged as essential equipment that enhances productivity and quality in the roofing materials sector. This article delves into the function, benefits, and future trends of roof tile making machines.

Understanding Roof Tile Making Machines

Roof tile making machines are specialized machinery designed to produce various types of roof tiles, including ceramic, concrete, and asphalt shingles. The machines automate the manufacturing process, providing efficiency and consistency that manual processes cannot match. They operate on principles that involve mixing raw materials, shaping them into tiles, and curing them to achieve durability and weather resistance.

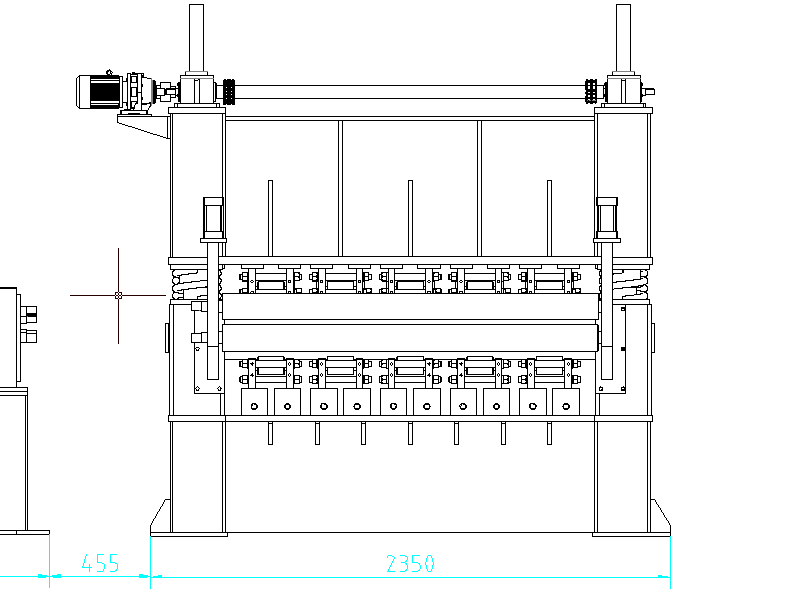

Typically, a roof tile making machine includes several components such as mixers, molds, hydraulic presses, curing ovens, and automated control systems. These components work synchronously to ensure high-quality tile production. The modern models available today are equipped with advanced technology, allowing for precise control over the manufacturing process and enabling the production of custom tile designs.

Advantages of Using Roof Tile Making Machines

Investing in a roof tile making machine offers numerous advantages for manufacturers. Some of the key benefits include

1. Increased Efficiency Automation in the production process significantly reduces the time required to manufacture tiles. High-capacity machines can produce thousands of tiles per day, allowing companies to meet high market demand without compromising quality.

2. Cost-Effectiveness While the initial investment for these machines may be substantial, the long-term savings in labor costs and increased production rate make them a cost-effective solution. Moreover, with less manual intervention, the likelihood of human error is reduced, leading to lower waste and material costs.

3. Consistent Quality Roof tile making machines are designed to ensure uniformity in size, shape, and texture. This consistency is vital for maintaining the aesthetic appeal of roofing materials and ensuring they meet industry standards.

4. Versatility Modern roof tile making machines can accommodate a variety of raw materials and can produce diverse types of tiles. This versatility allows manufacturers to cater to different customer preferences and market needs.

5. Reduced Labor Dependency By automating the production process, companies can lessen their reliance on manual labor. This shift not only mitigates the risks associated with labor shortages but also minimizes workplace accidents, contributing to a safer working environment.

Environmental Considerations

As environmental awareness grows, manufacturers are being urged to adopt sustainable practices. Roof tile making machines can be designed to use eco-friendly materials and processes. For instance, some machines are capable of utilizing recycled materials, reducing waste and lowering the carbon footprint of the manufacturing process.

Furthermore, advancements in technology have led to the development of energy-efficient machines that consume less power, contributing to sustainability in the production of roofing materials.

Future Trends in Roof Tile Making Machines

The future of roof tile making machines appears promising, with ongoing advancements in technology shaping the industry. Some key trends to watch include

1. Smart Technology Integration The incorporation of IoT (Internet of Things) technology into roof tile making machines can optimize production by providing real-time data on performance, maintenance needs, and production efficiency.

2. Customization Capabilities As consumer preferences evolve, there is an increasing demand for customized roofing solutions. Future machines will likely incorporate advanced design software that allows for easy adjustments in tile design and production specifications.

3. Automation and AI Further integration of automation and artificial intelligence could lead to even higher efficiency and quality control in tile production, making the manufacturing process seamless and more responsive to market demands.

Conclusion

The evolution of roof tile making machines has revolutionized the roofing materials industry, offering enhanced efficiency, quality, and sustainability. As technology continues to advance, these machines will play an increasingly pivotal role in meeting the construction demands of the future while adhering to environmentally friendly practices. Embracing this innovation is essential for manufacturers aiming to thrive in an ever-competitive market. The future is bright for the roofing industry, and roof tile making machines will be at the forefront of this transformation.