The Evolution and Importance of Roof Tile Rolling Forming Machines

In the construction and roofing industry, efficiency and quality are paramount. Among the innovations that have emerged to meet these demands, the roof tile rolling forming machine stands out as a game-changer. This advanced machinery not only streamlines the manufacturing process of roof tiles but also contributes significantly to the overall performance and aesthetics of roofing systems.

Understanding Roof Tile Rolling Forming Machines

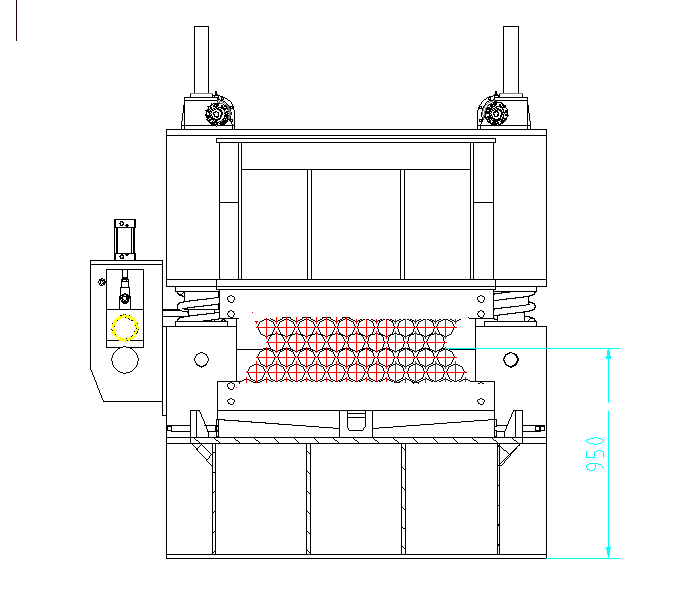

Roof tile rolling forming machines are specialized pieces of equipment designed for the continuous production of roof tiles from metal sheets. The process begins with the feeding of flat metal strips into the machine, where they are progressively shaped and cut into tiles. The rolling process utilizes a series of rollers that shape the metal into the desired profile, offering a seamless and precise finish. This technology significantly reduces the time and labor required compared to traditional methods, making it a cost-effective solution for manufacturers.

Advantages of Roof Tile Rolling Forming Machines

1. High Efficiency The automation of the tile production process allows for rapid output, enabling manufacturers to meet high demand without compromising on quality. This efficiency is particularly beneficial in large-scale construction projects where timelines are critical.

2. Quality and Consistency The precision engineering behind roof tile rolling forming machines ensures that each tile produced meets strict quality standards. The uniformity in size and shape not only enhances the aesthetic appeal of the roof but also improves its structural integrity.

3. Material Versatility These machines can work with a variety of materials, including galvanized steel, aluminum, and other metal alloys. This flexibility allows manufacturers to offer a range of products that meet different architectural styles and environmental requirements.

4. Customizability Modern roof tile rolling forming machines can be customized to produce various tile profiles and designs, catering to a wide range of customer preferences. This adaptability opens new markets for manufacturers and gives consumers more choices in roofing materials.

5. Cost-Effectiveness While the initial investment in rolling forming machines may seem high, the long-term savings in labor costs and waste reduction make it a worthwhile investment. The reduction in scrap material also contributes to a more sustainable manufacturing process.

The Future of Roof Tile Rolling Forming Machines

As technology continues to evolve, so too will the capabilities of roof tile rolling forming machines. Advancements in automation, such as artificial intelligence and machine learning, could lead to smarter machines that can detect flaws in real-time and make adjustments on the fly, enhancing product quality even further. Additionally, as sustainable practices become more critical in the construction industry, manufacturers may look towards using eco-friendly materials in their production processes, further improving the industry's environmental impact.

Furthermore, the increasing demand for durability and resilience in roofing materials, particularly in regions susceptible to extreme weather conditions, will drive innovation in this field. Manufacturers of roof tile rolling forming machines are likely to focus on producing tiles that not only look good but also withstand the test of time and environmental challenges.

Conclusion

The roof tile rolling forming machine is a vital tool in modern construction, facilitating the efficient production of high-quality roofing materials. With its numerous advantages, it represents a significant advancement in manufacturing technology, promising to shape the future of the roofing industry. As manufacturers continue to innovate and adapt to changing market demands, we can expect roof tile rolling forming machines to play an increasingly crucial role in ensuring that our buildings are not only functional but also aesthetically pleasing and sustainable.