The Evolution and Importance of Roof Tile Machines in Modern Construction

In the realm of construction, the roof is one of the most critical components of any building. It not only protects the structure from external elements like rain, snow, and wind, but also contributes significantly to aesthetic appeal and energy efficiency. As the demand for durable and visually appealing roofing materials rises, roof tile machines have become vital in the production of high-quality roof tiles. This article explores the evolution of roof tile machines, their significance in construction, and the future of this technology.

Historical Background

The production of roof tiles dates back to ancient civilizations, where clay was molded and baked into durable roofing materials. Over the centuries, the methods of manufacturing roof tiles have evolved dramatically. Initially, the process was labor-intensive and relied heavily on manual labor. However, the advent of industrialization brought about machinery that could automate the production process, vastly improving efficiency, consistency, and product quality. Roof tile machines emerged as a vital production tool, capable of creating a wide variety of tiles in a fraction of the time it would take traditional methods.

Types of Roof Tile Machines

Modern roof tile machines come in various configurations designed to meet specific production needs. The most common types include

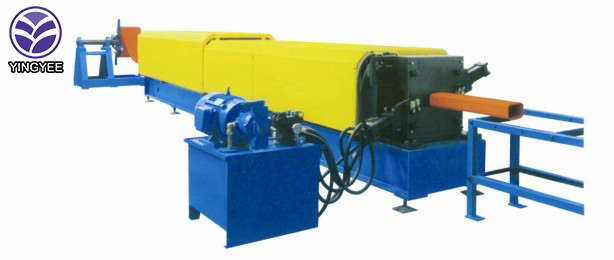

1. Extrusion Machines These machines use a process in which raw materials are forced through a mold to create tiles of desired shapes and sizes. This method is favored for producing continuous lengths of tiles, which are then cut to size.

2. Pressing Machines This type of machine utilizes molds to shape the tiles under high pressure. It is particularly effective for creating heavier, more robust tiles, commonly used in industrial applications.

3. Tile Forming Machines These machines form tiles from metal, plastic, or composite materials by shaping them into a finished product. They are increasingly popular due to their durability and flexibility in design.

4. Hydraulic Press Machines Known for their efficiency and precision, hydraulic pressing machines are used to produce high-quality concrete roof tiles. They enable manufacturers to create intricate designs and patterns while maintaining uniform thickness and strength of each tile.

Advantages of Using Roof Tile Machines

The adoption of roof tile machines has revolutionized the roofing industry. The primary advantages include

- Efficiency Machines can produce large quantities of tiles in a short amount of time, meeting high demand without compromising quality.

- Consistency Automated production ensures that each tile meets the same specifications, reducing variability and defects. This uniformity is crucial for installation and longevity.

- Cost-Effectiveness While there is an initial investment in machinery, the long-term cost savings from reduced labor and increased production speed are considerable.

- Customization Modern machines allow for a high degree of customization, enabling manufacturers to produce tiles that meet specific customer demands regarding size, color, and design.

Environmental Considerations

With increasing awareness of environmental issues, roof tile machines have also evolved to incorporate sustainable practices. Many manufacturers are now focusing on using recycled materials or reducing waste in the production process. Additionally, advancements in technology allow for energy-efficient machines that minimize their carbon footprint while maximizing output.

The Future of Roof Tile Machines

As technology continues to advance, the future of roof tile machines looks promising. Innovations such as 3D printing are beginning to see applications in roof tile manufacturing, allowing for even greater design flexibility and reducing material waste. Moreover, the integration of smart technologies, such as IoT (Internet of Things) systems, is paving the way for more responsive and efficient production environments.

In conclusion, roof tile machines play a crucial role in the construction industry, providing essential tools for the mass production of high-quality roofing materials. As the technology evolves, it is likely that these machines will continue to shape the future of roofing, supporting architectural advancements and sustainability initiatives in construction projects worldwide. The synergy between innovative machinery and traditional craftsmanship will undoubtedly lead to a new era in roof tile production, enhancing both functionality and design in modern architecture.