The Evolution and Importance of Roof Sheet Machines in Glazed Sheet Forming

In the construction and manufacturing industries, the demand for durable and aesthetically pleasing materials has given rise to numerous innovations. Among these, the roof sheet machine, specifically designed for glazed sheet forming, stands out as a remarkable development. This specialized machinery not only streamlines production but also enhances the quality of construction materials, thereby playing a critical role in modern building practices.

Understanding Roof Sheet Machines

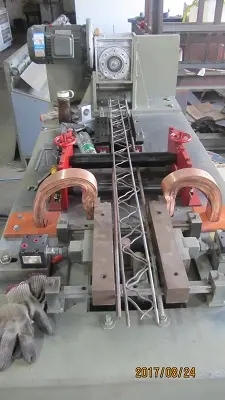

Roof sheet machines are specialized devices designed to produce roofing sheets from raw materials such as galvanized steel or aluminum. These machines can create a variety of profiles, and when specifically tailored for glazed sheets, they add a layer of finish that increases both aesthetic appeal and functional performance. Glazed sheet forming machines utilize advanced technology to ensure precise shape and dimensions, producing sheets that fit seamlessly into various architectural designs.

The glazing process involves applying a layer of protective coating, which enhances durability and weather resistance. This is particularly important in roofing applications where exposure to the elements can lead to rapid degradation. By incorporating a glazing technique, manufacturers can produce roofing sheets that resist rust, corrosion, and fading, ensuring longevity and low maintenance for end-users.

Efficiency in Production

One of the most significant advantages of automated roof sheet machines is their efficiency. Traditional methods of producing roofing materials were labor-intensive and time-consuming, often leading to inconsistencies in quality. With the advent of automated machinery, manufacturers can produce large volumes of roof sheets in a fraction of the time. These machines are designed to operate continuously, optimizing material usage and minimizing waste.

Moreover, modern roof sheet machines are equipped with advanced control systems that allow for real-time monitoring and adjustments during production. This not only enhances the precision of the glazed sheets being produced but also significantly reduces the likelihood of defects. As a result, manufacturers can maintain a higher standard of quality, thus building a stronger reputation in the marketplace.

Customization and Versatility

Another key feature of roof sheet machines is their ability to customize products according to client specifications. Builders and architects often have unique requirements based on the design and function of the structures they are working on. The capability to adjust the machine settings to create specific profiles, thicknesses, and finishes allows producers to meet diverse customer needs.

This versatility extends beyond mere design features; roof sheet machines can also accommodate various raw materials. Whether the project calls for lightweight aluminum sheets or robust steel options, manufacturers can easily switch materials, making it a resource-efficient solution for modern construction needs.

Economic Impacts

The economic implications of roof sheet machinery are profound. By streamlining production processes and reducing material waste, manufacturers can lower costs and increase their profit margins. Additionally, the ability to produce high-quality glazed sheets can open new markets and business opportunities. Construction companies prefer sourcing materials that offer both aesthetic value and durability, making glazed roof sheets increasingly desirable.

Furthermore, job creation is another positive aspect of this technological advancement. While automation minimizes some traditional labor roles, it also creates demand for skilled technicians who can operate and maintain these sophisticated machines. This shift in workforce requirements emphasizes the need for continued education and training in the construction and manufacturing sectors.

Conclusion

The roof sheet machine for glazed sheet forming exemplifies the intersection of technology and construction innovation. By enhancing production efficiency, maintaining high-quality standards, and offering customization options, these machines are reshaping the roofing materials landscape. As the construction demands evolve, the importance of such machinery will only continue to grow, enabling builders and manufacturers to rise to new challenges while ensuring that safety, durability, and aesthetics remain at the forefront of every project. Ultimately, the integration of glazed sheet forming technologies in roof sheet production is a testament to the ongoing evolution within the construction industry, paving the way for a more efficient and visually appealing future.