Roofing Sheet Making Machine Revolutionizing the Construction Industry

In the realm of construction and architecture, the materials used play a pivotal role in determining the longevity, durability, and aesthetic appeal of structures. Among these materials, roofing sheets stand out as essential components, providing shelter and protection against the elements. To meet the rising demand for quality roofing solutions, the roofing sheet making machine has emerged as a game-changer in the industry. This innovative machinery not only enhances production efficiency but also ensures high-quality outputs that comply with diverse building standards.

Understanding the Roofing Sheet Making Machine

A roofing sheet making machine is an industrial device designed to manufacture metal roofing sheets from raw materials, typically in the form of coils. These machines can process various types of metals, including galvanized steel, aluminum, and stainless steel, allowing manufacturers to produce sheets that cater to different climatic conditions and architectural styles.

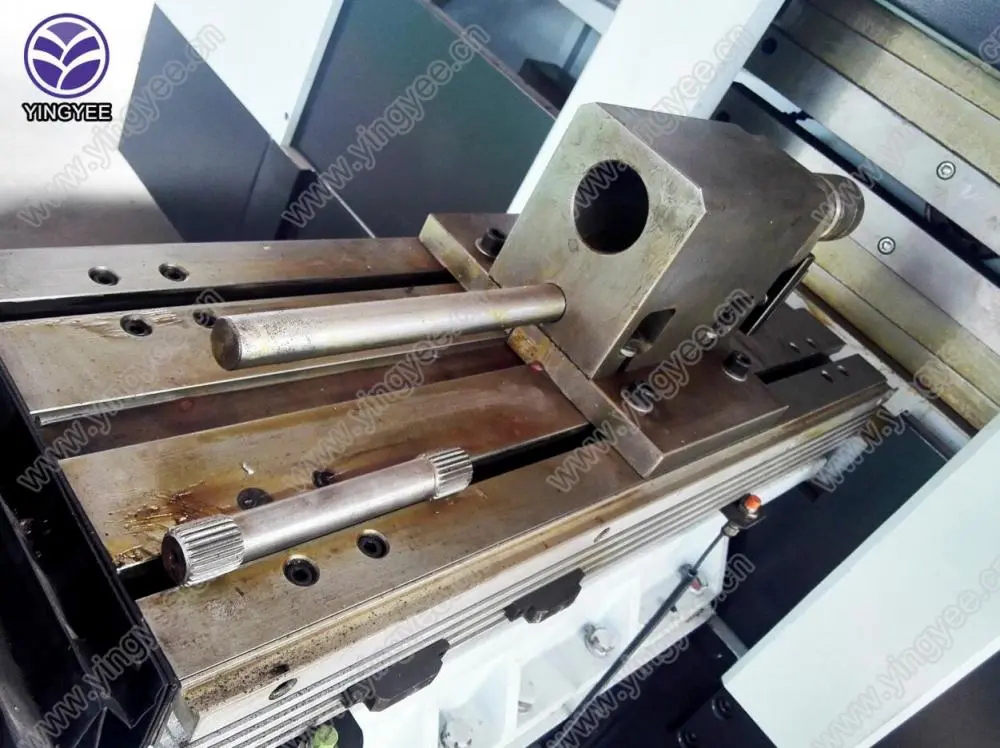

The operation of these machines involves several key processes unwinding, feeding, forming, and cutting. Initially, the metal coils are unwound and fed into the machine, which then processes the material through a series of rollers that shape it into the desired profile. Finally, the formed sheets are cut to the required lengths before being packaged for delivery.

Benefits of Using a Roofing Sheet Making Machine

1. Efficiency and Speed One of the most significant advantages of roofing sheet making machines is their ability to produce large quantities of roofing sheets in a relatively short period. Automated processes minimize manual labor and reduce production time, enabling manufacturers to meet tight deadlines and increasing overall productivity.

2. Customization Modern roofing sheet making machines are equipped with advanced technology that allows for customization of sheet sizes, thicknesses, and profiles. This flexibility is crucial for catering to specific project requirements, whether it be for residential, commercial, or industrial buildings.

3. Cost-Effectiveness By streamlining the production process and reducing labor costs, roofing sheet making machines contribute to significant savings for manufacturers. The initial investment in these machines can be recouped through increased output and reduced operational costs over time.

4. Quality Assurance Quality control is paramount in construction materials. Roofing sheet making machines are designed to deliver consistent quality, ensuring that each sheet meets stringent industry standards. Advanced features such as automatic thickness measurement and defect detection enhance the reliability of the products.

5. Eco-Friendly Production With growing environmental concerns, many manufacturers are turning to roofing sheet making machines that emphasize sustainability. These machines often utilize recyclable materials and reduce waste, contributing to greener production practices.

Application and Use Cases

The roofing sheets produced by these machines are versatile and widely used in various applications. They are ideal for residential homes, commercial buildings, warehouses, and agricultural structures. Different profiles, such as corrugated, tile, and flat sheets, are available to suit diverse architectural styles.

In addition to traditional applications, there is a growing trend toward using roofing sheets for green building projects. With advancements in technology, certain roofing sheets can now incorporate features like solar panels, enhancing energy efficiency and promoting sustainable construction practices.

Conclusion

As the construction industry continues to evolve, the roofing sheet making machine stands out as a vital tool that enhances efficiency, quality, and sustainability. Manufacturers that adopt this technology not only improve their production capabilities but also position themselves to meet the future demands of the market. With the ongoing advancements in machinery and material science, the evidence suggests that roofing sheet making machines will play an increasingly important role in shaping the skyline of our cities, one roof at a time. As this technology becomes more accessible, the possibilities for innovation in building design and functionality will undoubtedly expand, ushering in a new era in construction.