The Advantages of Roof Cold Roll Forming Machines

In the modern construction industry, efficiency and precision are paramount. Roof cold roll forming machines have emerged as a game-changer, streamlining the process of creating roof panels and various other metal structures. These machines utilize a continuous roll forming process, which allows for the consistent production of high-quality components. In this article, we will explore the workings of roof cold roll forming machines and their advantages in roofing applications.

Understanding Cold Roll Forming

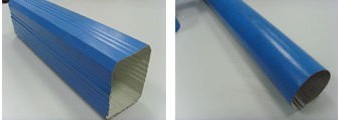

Cold roll forming is a process that involves feeding metal sheets into a series of rollers that shape the material at room temperature. Unlike traditional manufacturing methods, which may involve cutting and welding, cold roll forming shapes metal by bending it through a series of carefully designed rollers. This method retains the material's structural integrity while producing a product that is stronger and more durable than many alternatives.

Key Features of Roof Cold Roll Forming Machines

Roof cold roll forming machines are designed with several critical features that enhance their functionality. These machines typically include adjustable rollers, a programmable control system, and integration with cutting mechanisms for precise length specifications. The rollers can be customized to produce various profiles, accommodating different roofing designs and styles, ensuring versatility for manufacturers.

Efficiency and Cost-Effectiveness

One of the most significant advantages of using roof cold roll forming machines is their efficiency. The continuous nature of the process allows for high production speeds, which means that manufacturers can meet tight deadlines with ease. Furthermore, because the machines can create multiple profiles without the need for extensive retooling, production flexibility is enhanced, allowing companies to adapt quickly to changing market demands.

In addition to speed, these machines offer cost-effectiveness in terms of raw materials. The cold roll forming process typically minimizes waste, as it uses the entire sheet of material rather than cutting pieces out of larger sections. This not only reduces material costs but also contributes to more sustainable manufacturing practices.

High-Quality Output

The precision of roof cold roll forming machines guarantees high-quality output. The process produces components with exact dimensions, which is crucial in construction applications where accuracy is essential. Poorly fitting roofing materials can lead to leaks and other structural problems, so the reliable production of roof panels is vital. The uniformity of the products also facilitates easier installation, saving time and labor costs on-site.

Durability and Performance

Metal roofing panels manufactured using cold roll forming techniques often exhibit superior performance compared to those made using traditional methods. The cold working of metal increases its strength, making it more resistant to bending, warping, and damage over time. Roofing systems created with these machines are also more capable of withstanding harsh weather conditions, further enhancing their appeal in various climates.

Conclusion

Roof cold roll forming machines represent a significant advancement in roofing technology. Their ability to produce high-quality, durable metal components at a rapid pace, while being cost-effective and flexible in design, makes them indispensable tools for the construction industry. As the demand for efficient and sustainable building solutions continues to grow, these machines are likely to become even more prevalent, shaping the future of roofing manufacturing. Investing in roof cold roll forming technology is not only a step towards modernizing production capabilities but also a commitment to delivering superior products in the competitive construction market.