The Evolution and Importance of Roof Tile Rolling Machines

In the construction industry, the production of roof tiles plays a crucial role in building durable and aesthetically appealing structures. Roof tile rolling machines have emerged as essential equipment in the manufacturing process, revolutionizing the way tiles are produced. These machines are designed to create high-quality roof tiles efficiently, ensuring consistency and reliability across various projects.

Roof tile rolling machines work on the principle of continuous production, utilizing a series of rollers to shape metal sheets into the desired tile profile. Typically, these machines are equipped with advanced technology to enhance precision and reduce waste. The process begins with feeding raw materials, often steel or aluminum, into the machine. The rollers then gradually reshape the material into tiles, which can be further cut to the required lengths.

One of the primary benefits of using a roof tile rolling machine is the efficiency it brings to the manufacturing process. Unlike traditional methods, which are often labor-intensive and time-consuming, rolling machines allow for rapid production. This not only helps manufacturers meet growing demand but also reduces labor costs significantly. With the capability to produce thousands of tiles in a single day, these machines are essential for large-scale construction projects.

Moreover, roof tile rolling machines contribute to enhanced quality control. Modern machines are equipped with precise calibration systems that ensure each tile meets specific standards for thickness and dimension. This consistency is vital, as it affects not only the aesthetic appeal of the roof but also its structural integrity. High-quality tiles provide better resistance to weathering, improving the lifespan of the roofs they cover.

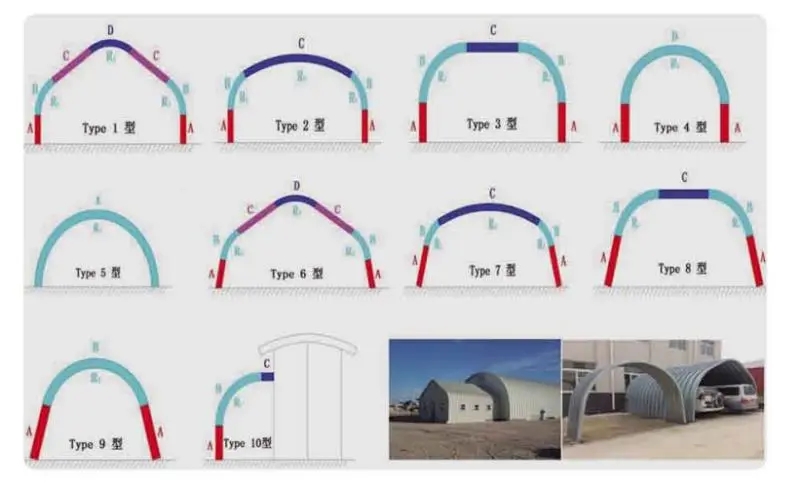

The versatility of roof tile rolling machines is another noteworthy aspect

. They can be customized to produce various styles of tiles, including traditional clay patterns, contemporary designs, and even specialized tiles for unique roofing needs. This adaptability allows manufacturers to cater to diverse market demands, providing clients with a wide range of options to choose from.In addition to their operational benefits, roof tile rolling machines are significant in terms of sustainability. Many modern machines are designed to minimize material waste and improve energy efficiency. As environmental concerns grow, manufacturers are increasingly looking for ways to reduce their carbon footprint, making these machines an integral part of sustainable building practices.

As the construction industry continues to evolve, the role of roof tile rolling machines becomes even more critical. With advancements in technology, such as automation and smart controls, the future of roof tile production looks promising. Manufacturers that leverage these innovations will likely gain a competitive edge, meeting the demands of a rapidly changing market.

In conclusion, roof tile rolling machines represent a significant advancement in construction technology. Their efficiency, quality control, versatility, and sustainability features make them indispensable in the modern manufacturing landscape. As the industry progresses, these machines will continue to play a vital role in shaping the roofs of the future, merging functionality with aesthetic appeal.