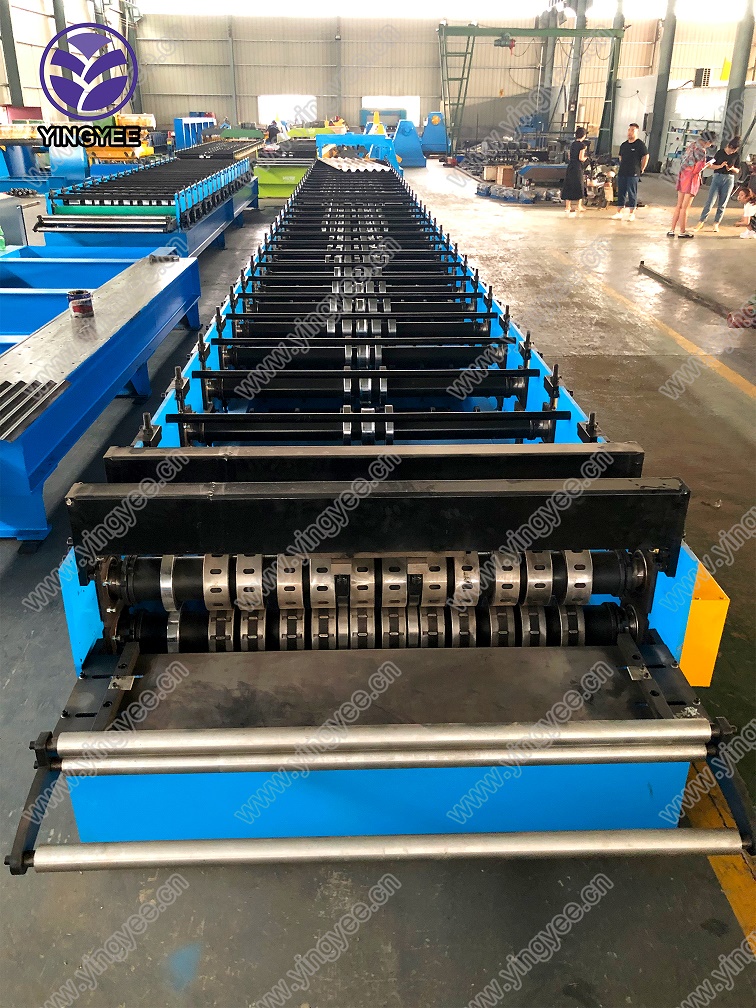

The roof wall panel roll forming machine is a revolutionary piece of equipment that has transformed the construction industry. This machine is designed to quickly and efficiently produce roof and wall panels for buildings of all shapes and sizes. The roll forming process involves feeding a coil of metal through a series of rollers that gradually shape the metal into the desired panel profile.

One of the key benefits of using a roof wall panel roll forming machine is the speed at which panels can be produced. Traditional methods of manufacturing roof and wall panels involve cutting and shaping individual pieces of metal, which is time-consuming and labor-intensive. With a roll forming machine, panels can be produced in a fraction of the time it takes using traditional methods, allowing for faster construction times and increased productivity.

In addition to speed, the roof wall panel roll forming machine also produces panels that are highly accurate and consistent in size and shape

. This ensures that panels fit together seamlessly during the construction process, resulting in a high-quality finished product. The machine can also produce panels in a variety of profiles and sizes, allowing for customization to meet the specific needs of each project.

Another advantage of using a roof wall panel roll forming machine is the cost savings associated with increased efficiency and productivity. By streamlining the production process and reducing labor costs, construction companies can save money on both materials and labor, ultimately leading to higher profit margins.

Furthermore, the use of a roll forming machine also reduces waste and improves sustainability in the construction industry. By producing panels to exact specifications, there is less scrap material left over, reducing the environmental impact of the construction process. Additionally, the machine can be programmed to produce panels with minimal material waste, further reducing the carbon footprint of a construction project.

Overall, the roof wall panel roll forming machine has revolutionized the way roof and wall panels are manufactured in the construction industry. Its speed, accuracy, cost savings, and sustainability make it an essential piece of equipment for any construction project. As technology continues to advance, the roll forming process will only become more efficient and effective, further improving the construction industry as a whole.