The Evolution and Importance of Roll Forming in Truck Chassis Manufacturing

In the landscape of automotive manufacturing, particularly in the production of truck chassis, the roll forming process has emerged as a significant technique. This method, which involves the continuous bending of flat metal sheets into predetermined shapes, has revolutionized the way truck chassis are designed and produced. By incorporating roll forming technology, manufacturers can enhance efficiency, reduce waste, and improve the overall quality of the final product.

Understanding Roll Forming

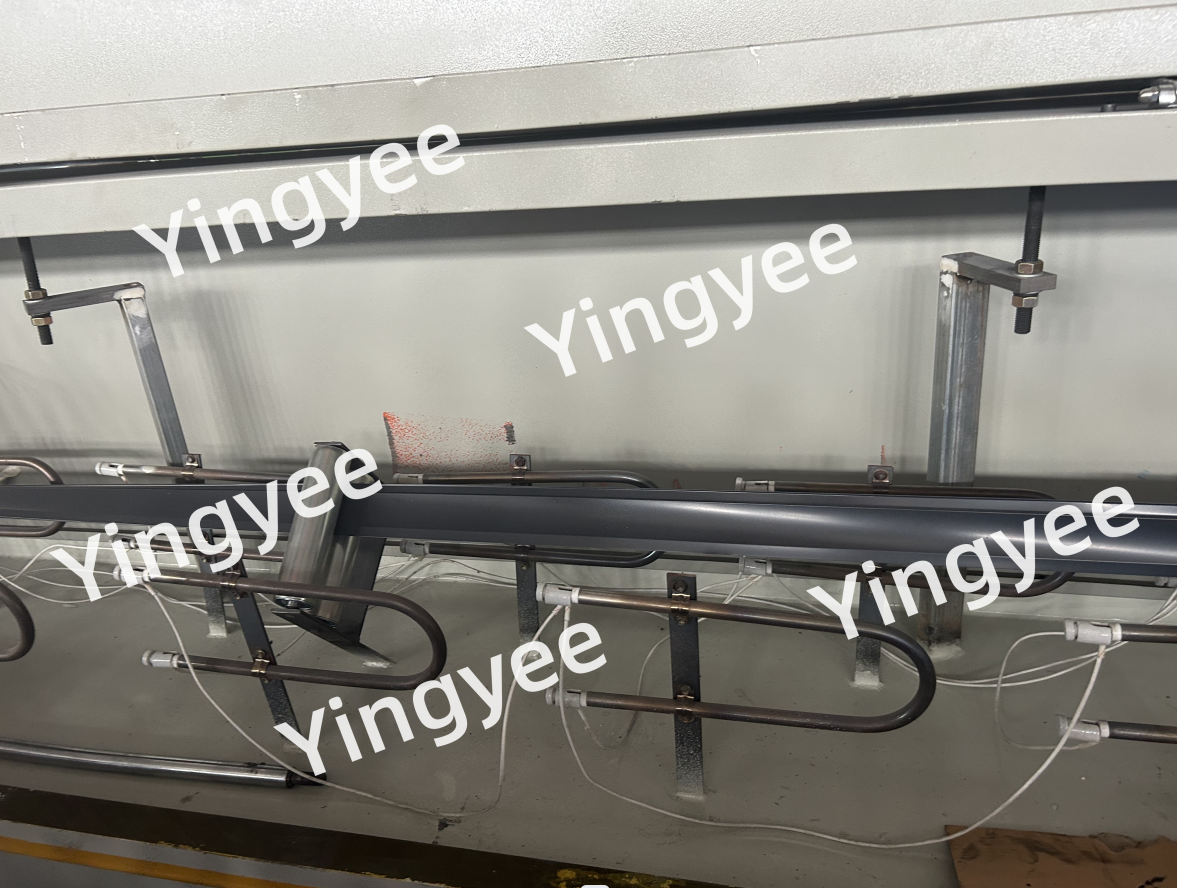

Roll forming is a process that involves feeding metal strips through a series of rollers, which progressively shape the material into specific cross-sectional profiles. This technique is particularly suitable for producing long lengths of uniform sections, making it ideal for truck chassis components. The process begins with raw metal sheets, typically made of high-strength steel or aluminum, which are then manipulated into desired shapes without the need for extensive cutting or welding.

One of the standout advantages of roll forming is its ability to maintain uniformity and precision throughout the manufacturing cycle. Since the process is continuous, it minimizes the risk of defects that can arise from traditional methods, such as stamping or cutting. This consistency is crucial in the automotive industry, where the integrity and performance of the chassis directly impact safety and durability.

Key Benefits of Roll Forming for Truck Chassis

1. Material Efficiency Roll forming significantly reduces material waste compared to other manufacturing methods. Because it uses continuous strips of metal, the process can maximize the use of raw materials, leading to cost savings and a lower environmental footprint.

2. Strength and Durability The cold working aspect of the roll forming process can enhance the mechanical properties of the metal, resulting in stronger and more durable truck chassis. This strength is essential for vehicles designed to carry heavy loads and withstand harsh conditions.

3. Design Flexibility Roll forming allows engineers to create complex shapes and profiles that can be tailored to specific truck designs. This flexibility supports innovative designs, enabling manufacturers to meet diverse customer requirements while optimizing performance.

4. Cost-Effectiveness Once the initial setup is complete, roll forming is a highly efficient process that can produce large quantities of truck chassis components at a relatively low cost. Reduced labor requirements and shorter production cycles further contribute to the overall cost-effectiveness of this method.

5. Reduced Lead Times The streamlined nature of roll forming minimizes the time required for production. As a result, manufacturers can meet market demands more swiftly, adapting to changes and fulfilling orders without significant delays.

Applications and Future Trends

In the realm of truck chassis manufacturing, roll forming is used to create various components, including beams, brackets, and reinforcements. These parts play a vital role in the structural integrity and functionality of trucks, ensuring that they can operate effectively under demanding conditions.

Looking to the future, the integration of automation and advancements in technology are poised to further enhance the roll forming process. The use of robotics and smart manufacturing techniques can optimize production lines, leading to even greater efficiency and precision. Moreover, as the demand for electric and hybrid trucks increases, roll forming will likely play a crucial role in fabricating lightweight and energy-efficient chassis designs.

Conclusion

The roll forming process represents a significant advancement in the manufacturing of truck chassis, offering numerous benefits that enhance efficiency, strength, and design versatility. As the automotive industry continues to evolve, the importance of innovative manufacturing techniques like roll forming will remain paramount. By embracing these technologies, manufacturers can ensure that they not only meet current demands but also pave the way for future developments in truck design and construction. The journey of roll forming in truck chassis production is just beginning, and its potential is as vast as the roads these vehicles will traverse.