The Evolution and Importance of Roll Forming Machines in Z Purling Production

Roll forming machines have revolutionized the production of various metal components, one of which is the Z purling. Z purlings are structural components commonly used in the construction industry, particularly in the building of warehouses, industrial structures, and agricultural facilities. These components are essential for providing support to roofs and walls, often influencing the overall stability and longevity of the structures they help create. The role of roll forming machines in manufacturing Z purling is crucial, as they provide a highly efficient, precise, and cost-effective method for producing these essential components.

Understanding Roll Forming Machines

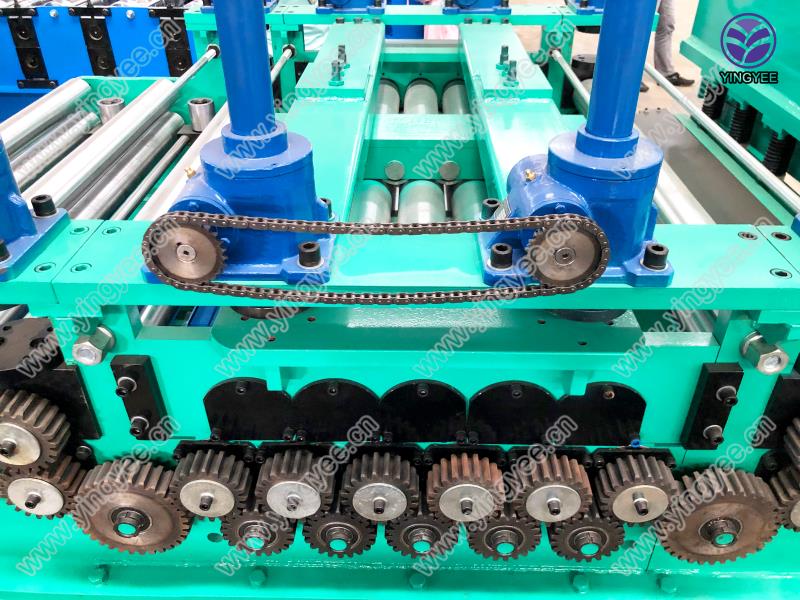

At its core, the roll forming process involves feeding a metal strip through a series of configured rollers, which sequentially shape the strip into the desired profile. This process can be utilized for a variety of materials, including steel, aluminum, and other metals. Roll forming machines are particularly well-suited for high-volume production, allowing manufacturers to produce long lengths of Z purling with consistent cross-sectional shapes and dimensions.

The design of roll forming machines has significantly evolved over the years. Modern machines are equipped with advanced technologies, including computer numerical control (CNC) systems, which enable precise adjustments and ensure uniformity across large production runs. The integration of these technologies has contributed to the enhanced accuracy and efficiency of roll forming processes, making it possible for manufacturers to meet the demanding specifications of today’s construction industry.

The Production of Z Purling

Z purling typically features a Z-shaped profile, which provides increased strength and stability when used as a structural support. The production of Z purling via roll forming entails several key steps. Initially, a coil of metal is fed into the roll forming machine, where it is progressively shaped into the Z profile by passing through a series of rollers. This process allows for the continuous production of Z purling, minimizing waste and maximizing efficiency.

One of the significant advantages of roll forming Z purling is the ability to customize dimensions to meet specific project requirements. Manufacturers can easily adjust the tooling and settings of the roll forming machine to produce Z purlings of varying sizes and thicknesses, catering to diverse construction applications.

Advantages of Roll Forming Z Purling

The use of roll forming machines for Z purling production offers several notable benefits

1. High Efficiency Roll forming is a continuous process, allowing for the rapid production of large quantities of Z purlings. This efficiency helps reduce production lead times and lowers overall costs.

2. Consistent Quality The precision of roll forming technology ensures that each piece of Z purling produced is uniform, meeting the high-quality standards required in construction.

3. Material Savings The roll forming process minimizes waste, as it can produce profiles with minimal off-cuts. This efficiency translates to cost savings and a reduced environmental impact.

4. Versatility Roll forming machines can be designed to create a variety of profiles, making them adaptable for different projects and needs within the construction industry.

5. Strength and Durability Z purlings produced through roll forming are often stronger and more resilient than those made using alternative methods. The continuous formation process enhances the structural integrity of the final product.

Conclusion

The role of roll forming machines in the production of Z purling cannot be overstated. As building practices evolve, and the demand for high-quality structural components increases, the efficiency and precision offered by roll forming technology position it as a vital manufacturing process in the construction industry. The ability to produce custom profiles quickly and economically, while maintaining high standards of quality, underscores the enduring importance of roll forming machines in contemporary construction practices. As we look to the future, the integration of advanced technology in roll forming processes will likely continue to enhance the production of Z purling and related structural components, supporting the ongoing growth and development of the construction sector.