The Rise of Roll Forming Machines in China Revolutionizing Manufacturing

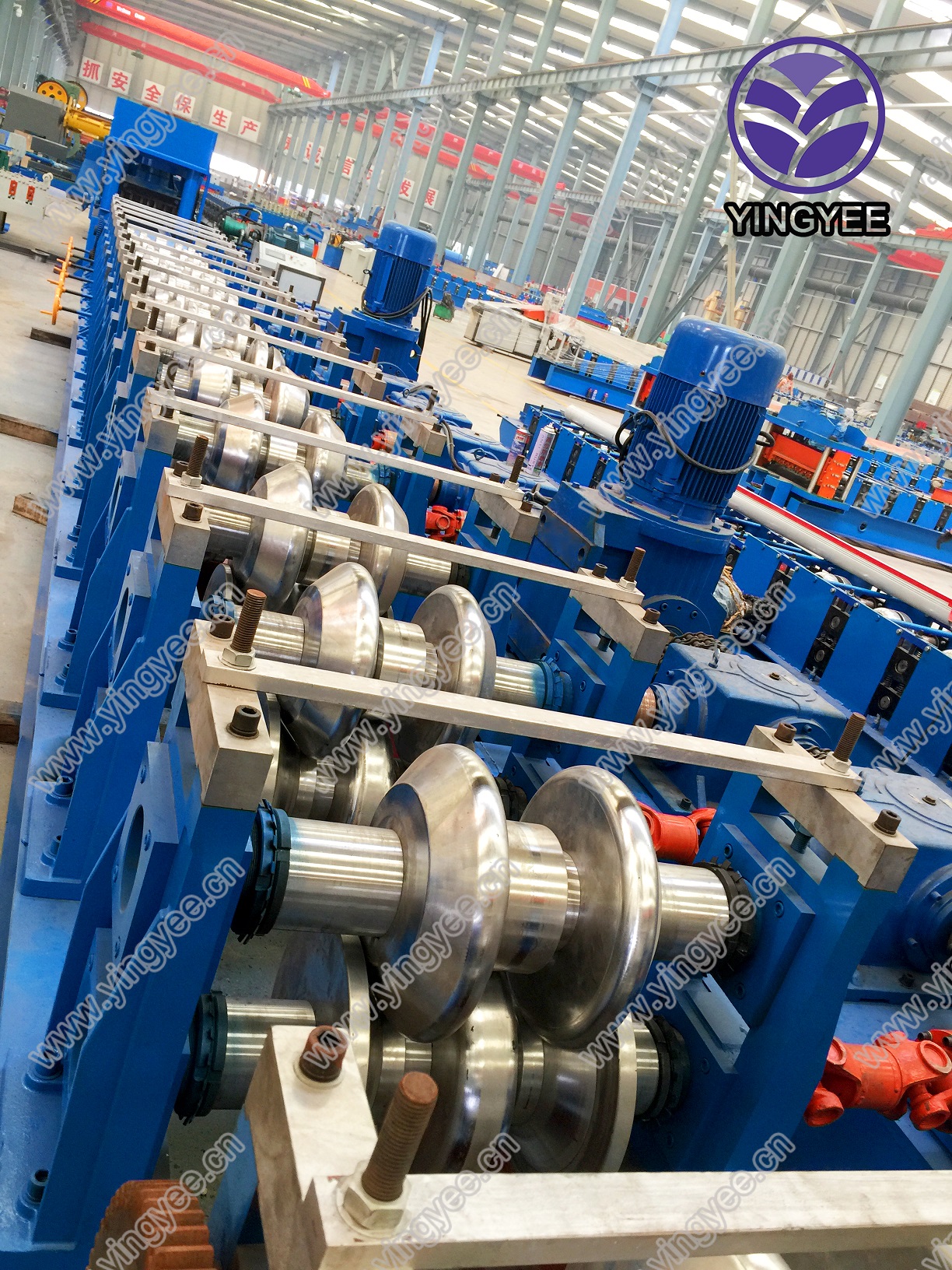

In recent years, China has emerged as a global leader in manufacturing, and one of the most significant contributors to this success is the advancement of roll forming machines. These machines are pivotal in the production of various metal components, which are essential in industries such as construction, automotive, and appliances. The roll forming process offers several advantages, including efficiency, precision, and versatility, making it an indispensable part of modern manufacturing.

The Rise of Roll Forming Machines in China Revolutionizing Manufacturing

One of the primary reasons for the growth of the roll forming machine market in China is the nation's booming construction industry. With ongoing urbanization and infrastructural development, the need for efficient and precise metal components has skyrocketed. Roll forming machines are capable of producing various products, including roofing panels, wall panels, and structural support sections, all of which are essential in construction projects. Moreover, as builders seek to improve sustainability, roll forming machines allow for the efficient use of materials, reducing waste and promoting environmentally friendly practices.

Technological advancements have also played a crucial role in enhancing the capabilities of roll forming machines. Manufacturers in China are investing heavily in research and development to create machines that are faster, smarter, and more energy-efficient. Automated systems and computerized controls are now commonplace, allowing operators to adjust parameters effortlessly and ensuring consistent quality throughout the production process. The integration of Industry 4.0 technologies, such as IoT and artificial intelligence, is further enabling manufacturers to monitor machine performance in real-time and optimize production lines accordingly.

The versatility of roll forming machines is another key factor behind their popularity in China. These machines can work with a wide range of materials, including steel, aluminum, and even non-ferrous metals. This adaptability allows manufacturers to cater to diverse sectors, from automotive parts to metal furniture. Customization options also enable companies to produce tailored solutions that meet specific requirements, thereby increasing their competitiveness in the market.

Furthermore, the competitive edge of Chinese roll forming machine manufacturers is supported by cost-effective production processes. With access to abundant raw materials and a skilled workforce, Chinese manufacturers can produce machines at lower prices while maintaining high quality. This has made roll forming machines accessible not only to domestic companies but also to international markets seeking reliable and affordable manufacturing solutions.

In conclusion, roll forming machines have become a cornerstone of China's manufacturing landscape, significantly contributing to the country's economic growth. Their ability to produce high-quality, precision metal components at an impressive speed makes them invaluable in various industries. As technology continues to evolve, and with ongoing investments in innovation, the roll forming machine industry in China is poised for further growth, solidifying its status as a key player in the global manufacturing sector. The future of roll forming in China looks bright, promising enhanced efficiency and sustainability for years to come.